Step 6 — adjust indoor-fan speed – Carrier 012 User Manual

Page 13

Step 6 — Adjust Indoor-Fan Speed —

Adjust in-

door fan speed to meet jobsite conditions.

For units with electric resistance heating, required mini-

mum L/s (cfm) is 1062 (2250) for 50LJQ008 and 1416 (3000)

or 50LJQ012, with the following exceptions.

UNIT

50LJQ

UNIT

VOLTAGE

HEATER

kW

UNIT

CONFIG-

URATION

REQUIRED

MINIMUM

L/s

Cfm

012

220

50.0

Horizontal

or Vertical

1534

3250

400

50.0

Horizontal

or Vertical

1605

3400

Tables 5A and 5B show fan rps and rpm at motor pulley

settings. Refer to Tables 6-13 to determine fan speed

settings.

Fan motor pulleys are factory set for speed shown in

Tables 1A and 1B.

To change fan speed:

a. Shut off unit power supply.

b. Loosen belt by loosening fan motor mounting nuts. See

Fig. 18.

c. Loosen movable pulley flange setscrew (see Fig. 19).

d. Screw movable flange toward fixed flange to increase speed

and away from fixed flange to decrease speed. Increasing

fan speed increases load on motor. Do not exceed maxi-

mum speed specified in Tables 1A and 1B.

e. Set movable flange at nearest keyway of pulley hub and

tighten setscrew (see Tables 1A and 1B for speed change

for each full turn of pulley flange).

To align fan and motor pulleys:

a. Loosen fan pulley setscrews.

b. Slide fan pulley along fan shaft.

c. Make angular alignment by loosening motor from mount-

ing plate.

To adjust belt tension (see Fig. 18):

a. Loosen fan motor mounting bolts.

b. Slide motor mounting plate away from fan scroll for proper

belt tension (13 mm [

1

⁄

2

-in.] deflection with one finger)

and tighten mounting bolts.

c. Adjust bolt and nut on motor mounting plate to secure

motor in fixed position.

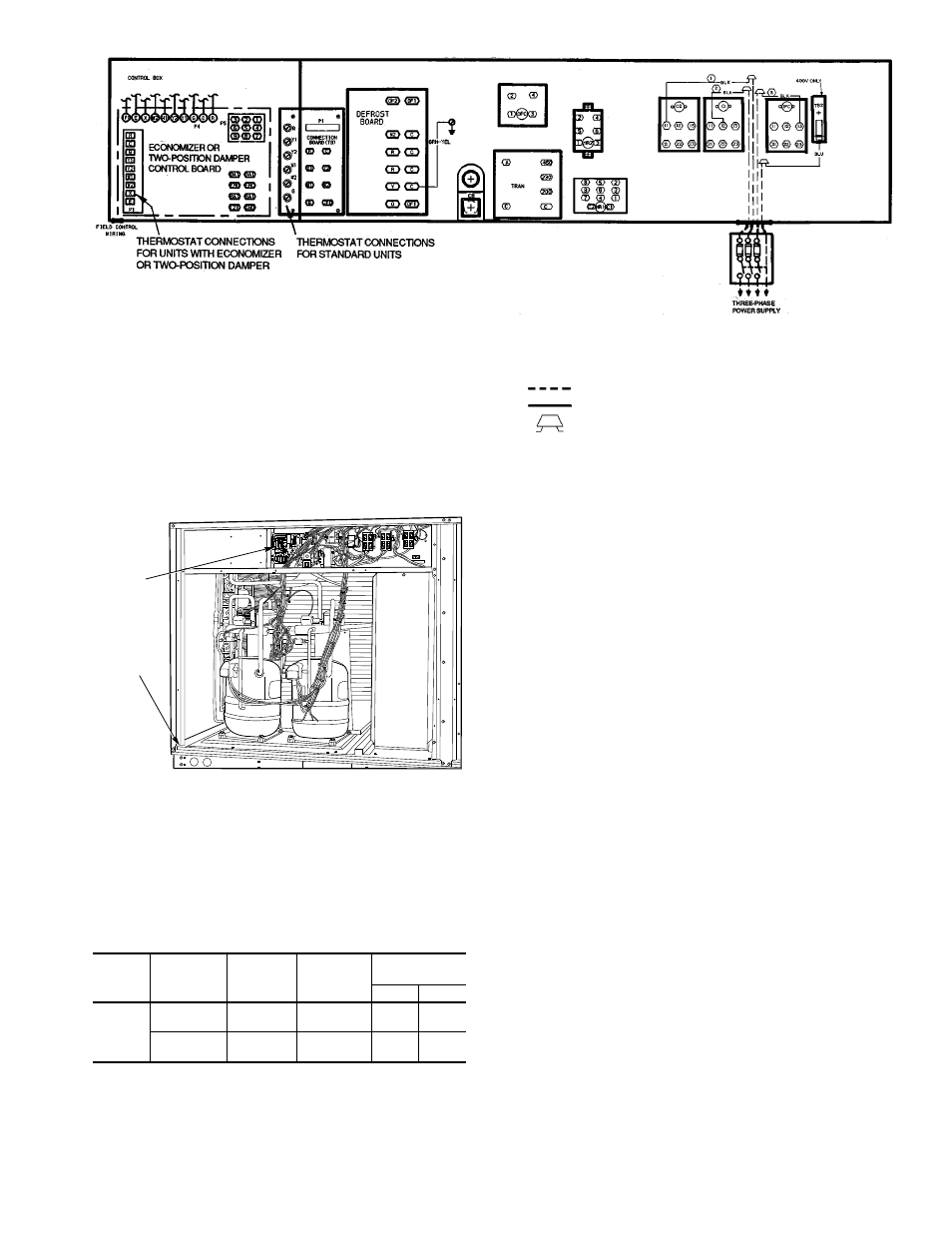

LEGEND

BAT

— Battery

C

— Contactor

CB

— Circuit Breaker

DAT

— Discharge-Air Thermistor

EMC/EMFC — Energy Management Closed

EMO/EMFO — Energy Management Open

EQUIP

— Equipment

GND

— Ground

HR

— Heater Relay

IFC

— Indoor-Fan Contactor

OFC

— Outdoor-Fan Contactor

P

— Plug

TB

— Terminal Board

TRAN — Transformer

Field Wiring

Factory Wiring

Splice Connection (Factory Supplied)

Fig. 16 — Field Wiring Connections

UNIT

CONTROL

BOARD

RACEWAY

Fig. 17 — Field Control Wiring Raceway

13