Options, Flow rate range table, Flow sensor selection – Culligan HD-726 User Manual

Page 9

TM

Commercial Systems

©2000 Culligan International Co.

1-800-CULLIGAN

www.culligan.com

DCO 992196

Printed in USA 01/00

SL-0064

Moore Part No. 49004

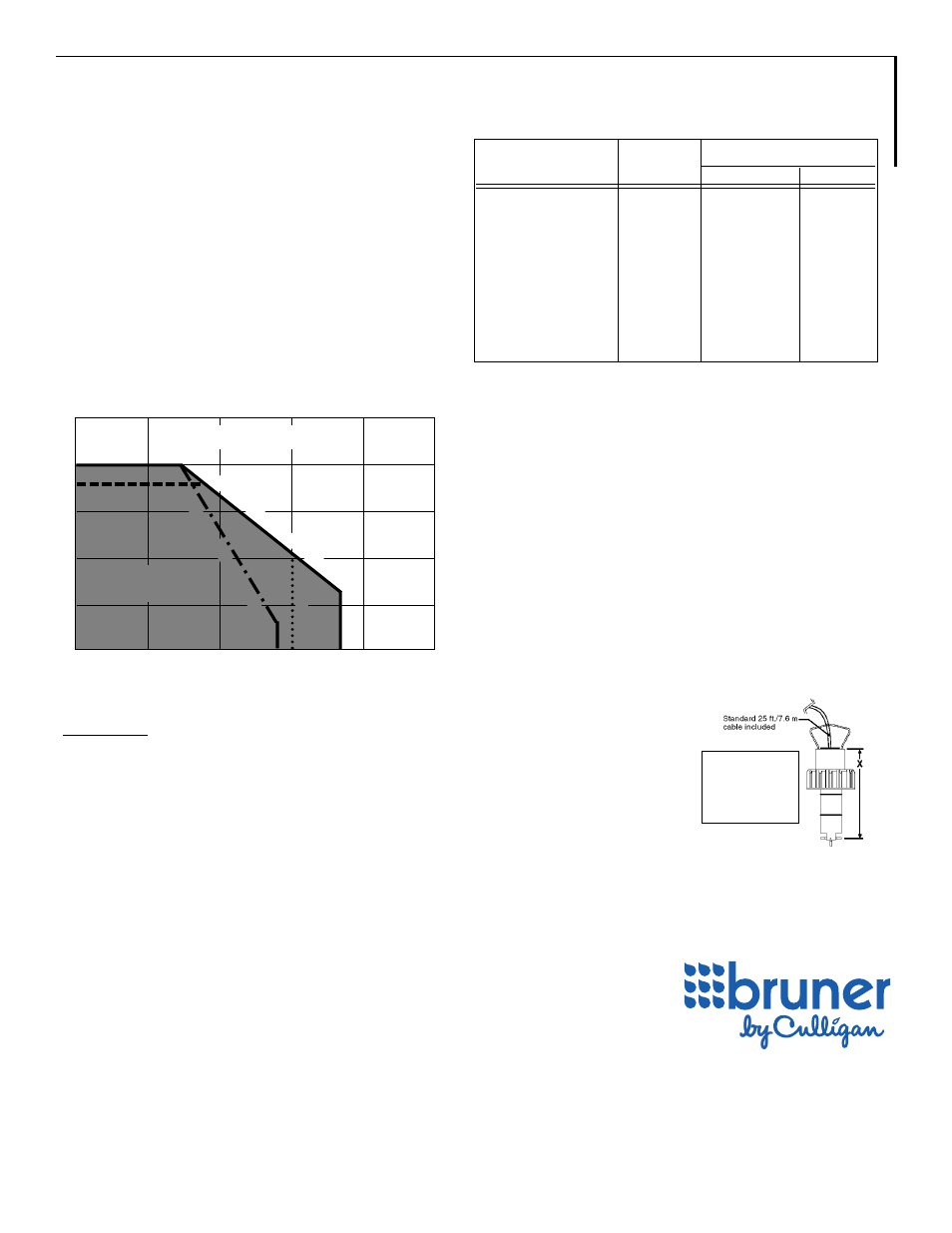

Flow Sensor Selection

To select the flow sensor package that best fits your requirements,

consider these application parameters:

1. Determine Installation Fitting Type – fittings are available for a

variety of piping materials.

2. Determine Installation Fitting Size – identify the HIGHEST

anticipated flow rate which would occur regularly thru EACH tank

of a single/multiple tank network. Match this value against those in

the MINIMUM and MAXIMUM FLOW column of the Flow Rate

Range Table to find the corresponding installation Fitting Pipe Size.

3. Verify Temperature/Pressure Operating Range – the maximum

operating pressure for the XLF series flow sensor is dependent on

the measured fluid temperature and type of installation fitting. Refer

to the Temperature/Pressure Graph for operating range. Refer to

OPTIONS paragraph for applications requiring a higher

temperature/pressure rating.

† PRESSURE LOSS FORMULA (S.G.=1.0)

( )

= Pressure Loss @ Actual Flow

(PSI) (GPM)

Options

Installation Fitting Service Plug:

Allows resumption of flow after depressurization and removal of flow

sensor element.

Wet Tap Assembly:

Provides a safe and fast method of removing a flow sensor element

without shutting off flow and pressure.

(Maximum Pressure – 100 psig @ 68

0

F; Maximum Temperature – 140°F

@ 25 psig)

High Temperature/Pressure Applications:

Contact factory for pressures up to 1,500 psig and temperatures up to

300°F for stainless steel flow sensors.

Actual Flow (GPM)

C

V

Factor

■

200

150

100

50

0

50

0

F

100

0

F

150

0

F

200

0

F

250

0

F

Pressure (PSIG)

Operating Temperature

Temperature/Pressure Relationship Table

Operating Range

Flow Sensors

And Installation Fittings

For Temperature/Pressure Conditions beyond

Operating Range of XLF Sensors see OPTIONS

Metal

Tees 0.5 to 2 in./M

etal W

eld-o-lets 2.5 to 8 in.

Bronz

e

Metal W

eld-o-lets and Iron Saddles 10 in.-up

Iron Saddles 2 to 8 in.

▲ ■

Installation Fitting

Cv

Flow Rate Range – (GPM)

Pipe Size – (Inches)

Factor

Minimum

▲

Maximum

1

**

39.0

0.7

44.0

11/4 **

56.0

1.2

80.0

11/2 **

84.0

1.7

110.0

2

**

157.0

2.8

187.0

21/2 ***

273.0

4.5

298.0

3 ***

483.0

6.9

460.0

4 ***

977.0

11.9

793.0

5 ***

1750.0

18.7

1247.0

6 ***

2846.0

27.0

1800.0

8 ***

5773.0

47.0

3118.0

10 ***

10,660.0

74.0

4915.0

Flow Rate Range Table

▲ Choose the Installation Fitting Pipe Size principally on the MINIMUM flow rate that would

occur REGULARLY in the treated water stream of each water treatment tank.

DO NOT OVERSIZE THE INSTALLATION FITTING!

■ C

V

= flow rate (GPM) @ 1.0 psi head loss; 60°F water temperature.

includes worst case requirement of 50 pipe diameters before and 5 pipe diameters

following the flow sensor location assuring minimum flow turbulence.

(

)

Specifications

Pressure Loss @ maximum rated flow: Less

than 3.5 psig. See formula †

• includes head loss of required straight length

of pipe both before and after flow sensor

location.(maximum requirement –55 diameters)

C

V

Factor:

■

See Flow Range

Table

Flow Rate Range:

0.3 thru 20 feet per

second fluid velocity

Output Linearity:

± 1% of maximum

range

Accuracy:

± 1% of maximum

range

Repeatability:

± 0.5% of full

range

Wetted Materials:

Polypropylene, Viton,

Titanium, PVDF

*Maximum

Temperature:

185°F @ 25 psig

*Maximum

Pressure:

180 psig @ 68

0

F

Installation Requirements:

*Maximum wire length 200 ft. –contact

between sensor and factory for greater

IQS/3 Controller

distance requirements

*Number of pipe

15 minimum/

diameters required

55 maximum

adjacent to flow

sensor location

dependent on source

of upstream turbulence:

Electrical Output:

Open Collector,

*Requires DC Current

transistor, sinking

from IQS/3;+5VDC

@ 10 ma.

Environmental:

Ambient temperature

-4

0

F to 122

0

F

Relative Humidity:

0% to 100%

Non-condensing

Dimensions:

X:

1/2" thru 4" = 3.50"

5" thru 8"

= 5.00"

10" up

= 7.75"

*Refer to table for temperature/pressure/

installation fitting relationships.

** Threaded Tee Sch 40 Galv. Pipe

*** Cast Iron Saddle Sch 40 Pipe

F

LOW

S

ENSOR

A

PPLICATION

D

ATA