Culligan Iron-Cleer User Manual

Page 19

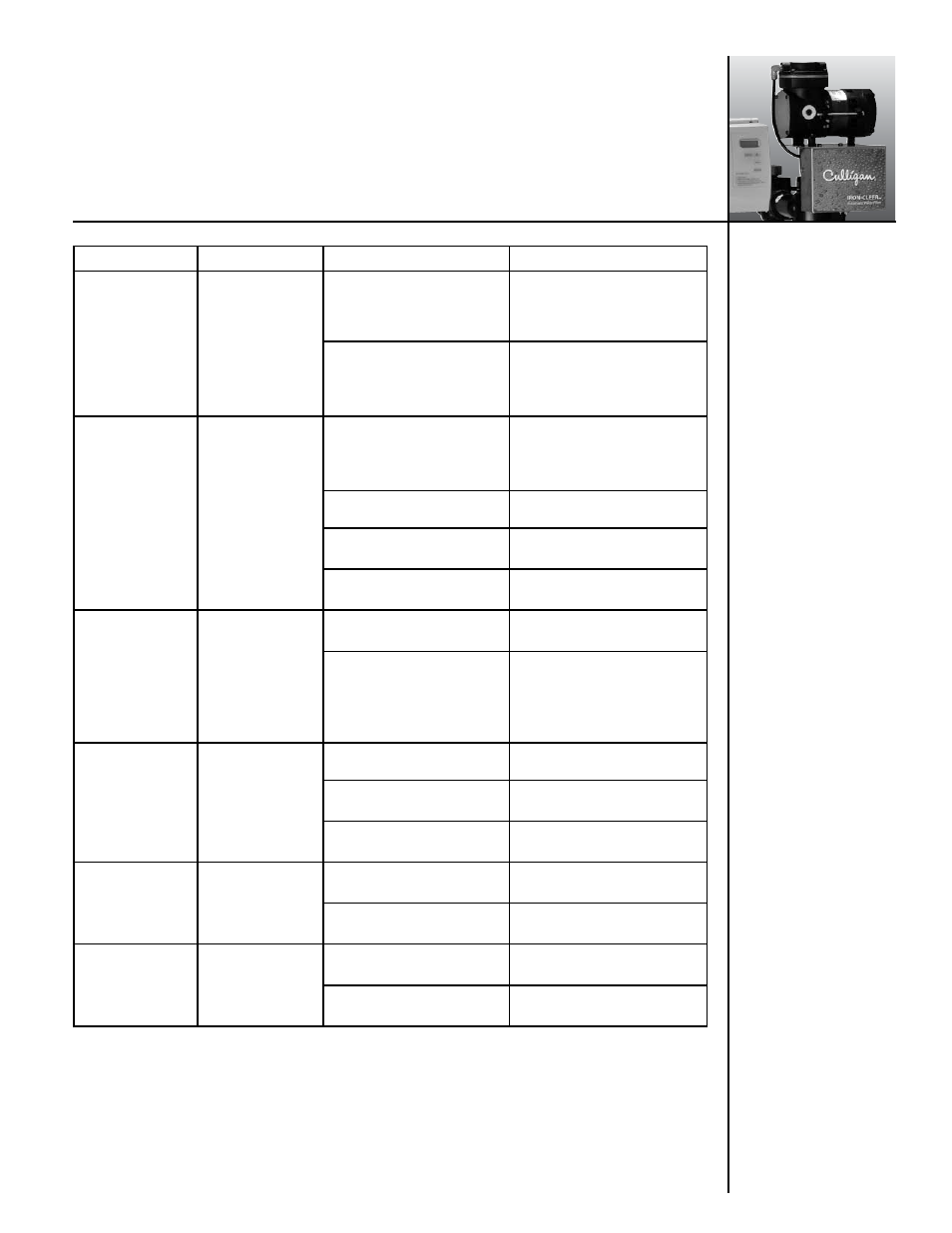

15

Complaint

Problem

Cause

Solution

Excessive

noise during

regeneration.

A. Howling

or whistling

noise during

regeneration

cycle.

1. Inadequate drain line

size.

1. Call your Culligan dealer

for service.

2. Drain line is vibrating

against other pipes,

conduits, pipe hangers, heat

ducts, floor joists,etc.

2. Call your Culligan dealer

for service.

Water is

running to drain

continuously.

A. Control

valve is stuck

in regeneration

cycle.

1. Electrical service

to control(s) has been

interrupted.

1. Assure continuous

electrical service is available.

(check plug, breaker, fuse,

etc.)

2. Faulty circuit board.

2. Replace circuit board..

3. Faulty drive motor.

3. Call your Culligan dealer

for service.

4. Foreign material lodged

in piston.

4. Call your Culligan dealer

for service.

Blue green

staining.

A. Corrosive

water condition in

copper distribution

piping system.

1. Low pH condition of the

raw water supply.

1. Call your Culligan dealer

for service.

2. In rare occasions,

highly aerated water in

combination with a specific

water supply can create a

slightly corrosive condition.

2. Call your Culligan dealer

for service.

Compressor

doesn’t run.

1. Compressor unplugged.

1. Plug it in.

2. Relay settings incorrect.

2. Call your Culligan dealer

for service.

3. Bad relay.

3. Call your Culligan dealer

for service.

Compressor run

with excessive

noise.

1. Dead head pressure is

65 psi.

1. Call your Culligan dealer

for service.

2. Dead head pressure is

65 psi.

2. Call your Culligan dealer

for service.

Compressor runs

continuously.

1. Incorrect relay settings

1. Call your Culligan dealer

for service.

2. Bad relay.

2. Call your Culligan dealer

for service.