Level bar, Hitch assembly, Level bar hitch assembly – Great Plains 3000TM Predelivery Manual User Manual

Page 14

10

1800-3000TM

Great Plains Manufacturing, Inc.

586-536Q

03/19/2014

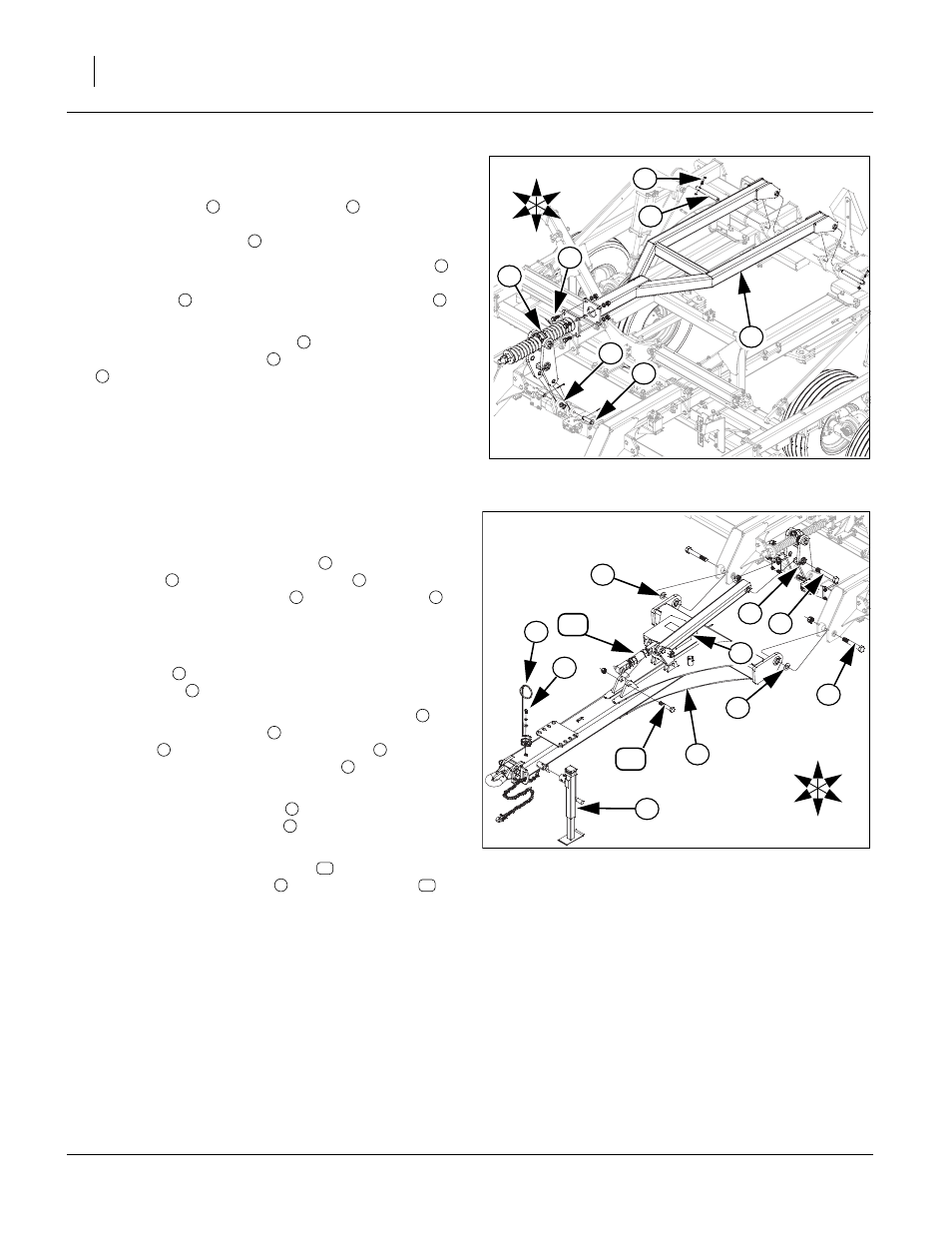

Level Bar

Refer to Figure 9

31. Attach level bar

with 1 x 9 1/2 pin

. Align hole in pin

and holes in collars on outside of torque tube ears, install

3/8 x 2 1/4 Gr. 8 bolts

and 3/8 nylock lock nuts.

32. Align bottom holes on h-bracket spring assembly

with

ears on front of center brace bar, secure with 1 x 3 1/4

usable pins

, 1.5 x 1.0 x.075 machine washers

and

3/16 x 2 cotter pin.

33. Attach front plate of level bar

with rear plate of h-

bracket spring assembly

with 3/4 x 2 Gr. 8 hex bolts

, 3/4 lock washers and 3/4 nuts.

34. Bolts may be tightened to specs, See “Torque Values

Chart” on page 26 and cotter pins bent

Hitch Assembly

Refer to Figure 10

35. Remove the 1 1/4 x 8 Gr. 8 bolts

from the rear of hitch

assembly

. Bolt the hitch assembly

to center frame

with the 1 1/4 x 8 Gr. 8 bolts

, 1 1/4 flat washer

(one

side of uniball to take up space) and 1 1/4 top lock nuts.

Tighten bolts snug, do not torque, as the hitch must pivot

freely.

36. Install jack

on front outside of hitch to support the

front of hitch

for the rest of assembly.

37. Remove 1 1/4 x 8 1/2 Gr. 8 special thread bolt

from

front short level bar tube

. Align holes in rear of level

bar tube

and center hole of h-bracket

. Install the 1

1/4 x 8 1/2 Gr. 8 special thread bolt

from the left side

and secure with 1 1/4 top lock nut.

38. Bolt the spring hose holder

to welded nut on front of

hitch with 1/2 x 1 Gr. 5 bolt

, 1/2 flat washer and 1/2

lock washer.

39. The front of the level turnbuckle

may need attached

to ears on hitch assembly

with 1 x 6 hex bolt

and 1

top lock nut

40. Bolts may be tightened to specs, See “Torque Values

Figure 9

Level Bar

42389

2

6

5

4

1

3

U

D

F

B

L

R

7

1

2

3

4

5

6

1

4

7

Figure 10

Hitch

42388

3

4

1

6

2

8

9

7

5

U

D

F

B

L

R

3

10

11

2

1

1

2

3

4

1

5

6

6

7

5

8

9

10

1

11