Great Plains 3P600 Operator Manual User Manual

Page 31

Great Plains Manufacturing, Inc.

Troubleshooting

27

2011-10-21

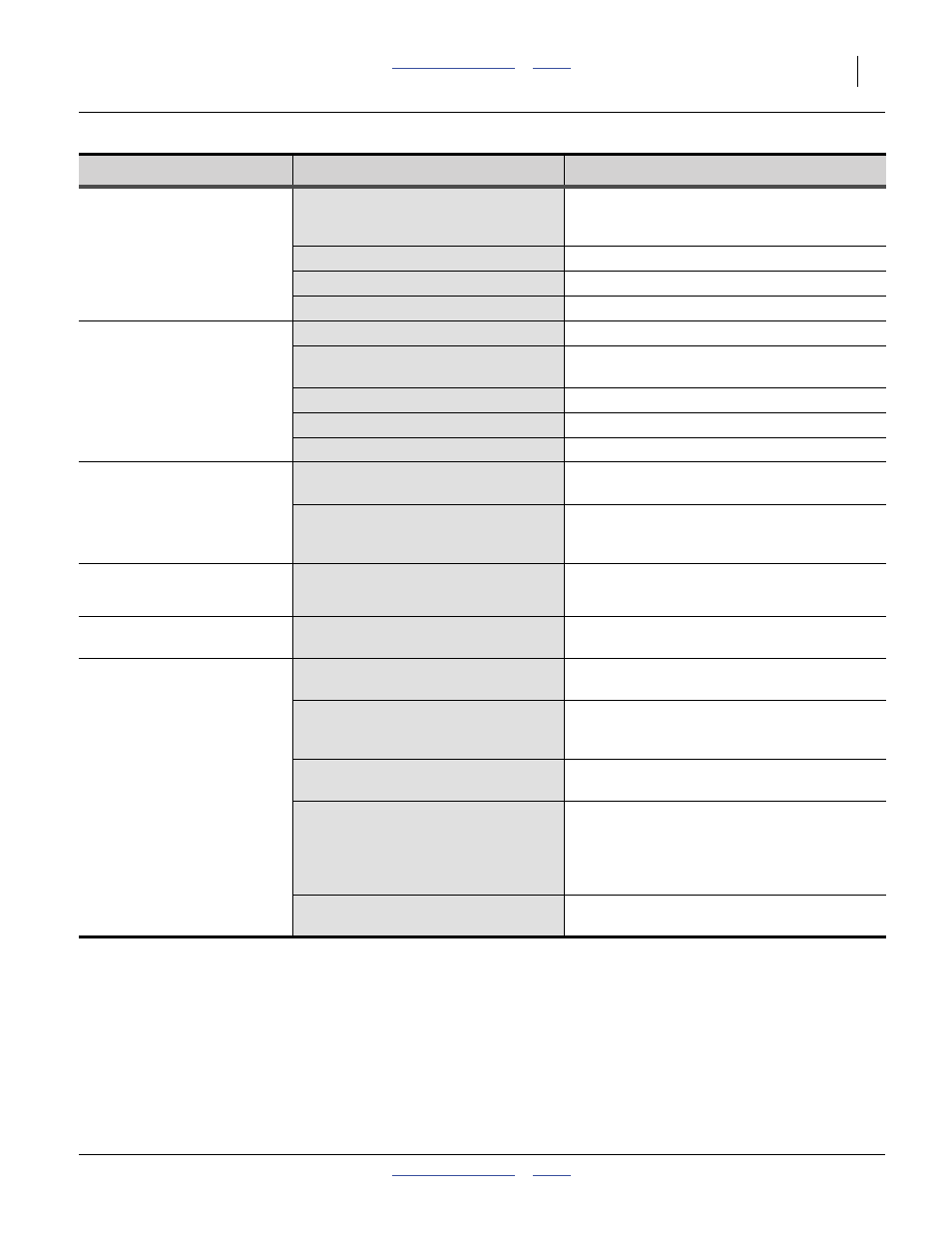

Boxes not emptying

evenly

Some boxes do not have same

number of feed cups between each

divider of bulkhead.

Load more material than required.

Re-distribute when re-loading.

Main box seed cup door setting

Set all doors the same, per seed size.

Seed plug(s) installed

Remove seed plug(s).

Meter or tube blocked

Clear blockage.

Press wheel or openers

plugging

Planting conditions too wet

Wait until drier weather.

Too much down pressure on openers

Reduce down pressure on openers

(page 21).

Backed up with drill in the ground

Clean out and check for damage.

Failed disc bearings

Replace disc bearings.

Scraper worn or damaged

Replace scraper.

Feed cup sprockets

locked up or twisted feed

cup drive shaft

Foreign matter lodged in one or more

feed cup sprockets

Clean out feed cup sprockets. Use clean

seed.

Dried liquid insecticide inside feed

cups

Remove build up by disassembling each feed

cup and scraping foreign substance from turn

surfaces.

Small seeds box not

emptying evenly

Aw~usueg g+divider (Option) not seˇ!

evenly

Move adjustable divider to create more

volume in areas that run out first.

Chain fouling

Debris in retainer clip

Be sure retainer clip is facing opposite way of

chain travel (page 31).

Acremeter inaccurate

Excess wheel slippage

Check frame height. If correct, solution may

be to wait for drier conditions.

Passes misaligned

Check that planting passes are not leaving

gaps (under-reporting area) or causing

overlap (over-reporting area).

Wheel slippage is varying from

nominal

If variance is consistent, develop a correction

factor for your conditions.

Check that acremeter is for your drill.

Activate display. Lower left corner must be:

3P500: 928 revs/ac or 2293.1 revs/ha

3P500V: 928 revs/ac or 2293.1 revs/ha

3P600: 786 revs/ac or 1942.2 revs/ha

Contact dealer if otherwise.

Acremeter battery failing

Replace acremeter (page 16). Unit is sealed

and battery is not replaceable.

Problem

Cause

Solution