Adjustments, Planting depth, Seed rates – Great Plains 3P600 Operator Manual User Manual

Page 22

2011-10-21

18

3P500, 3P500V & 3P600

Great Plains Manufacturing, Inc.

Adjustments

To get full performance from your drill, you need an

understanding of all component operations, and many

provide adjustments for optimal field results. Some of

these have been covered earlier in this manual.

Even if your planting conditions rarely change, some

items need periodic adjustment due to normal wear.

Planting Depth

Setting nominal planting depth, and achieving it

consistently, is affected by multiple adjustable drill

functions. From greatest to least effect they are:

• Opener depth (press wheel height)

• Opener down-pressure (spring)

• Row unit down-pressure spring

• Opener (tool bar) height

• Disc blade adjustments (as discs wear)

Seed Rates

Seeds are applied by fluted feed meters driven by the

gauge wheel. Independent mechanisms control the rate

for each box. Changing one box rate does not affect the

other.

Details of rate setting are in the 118-794B Seed Rate

Manual

Main Box seed rate is controlled by adjustments for:

• Drive Type gearbox lever

• Rate handle at seed box (drill front)

• Feed Cup Door handle (one each seed tube)

Small Seeds (Option) rate is controlled by a Rate

Handle (drill rear).

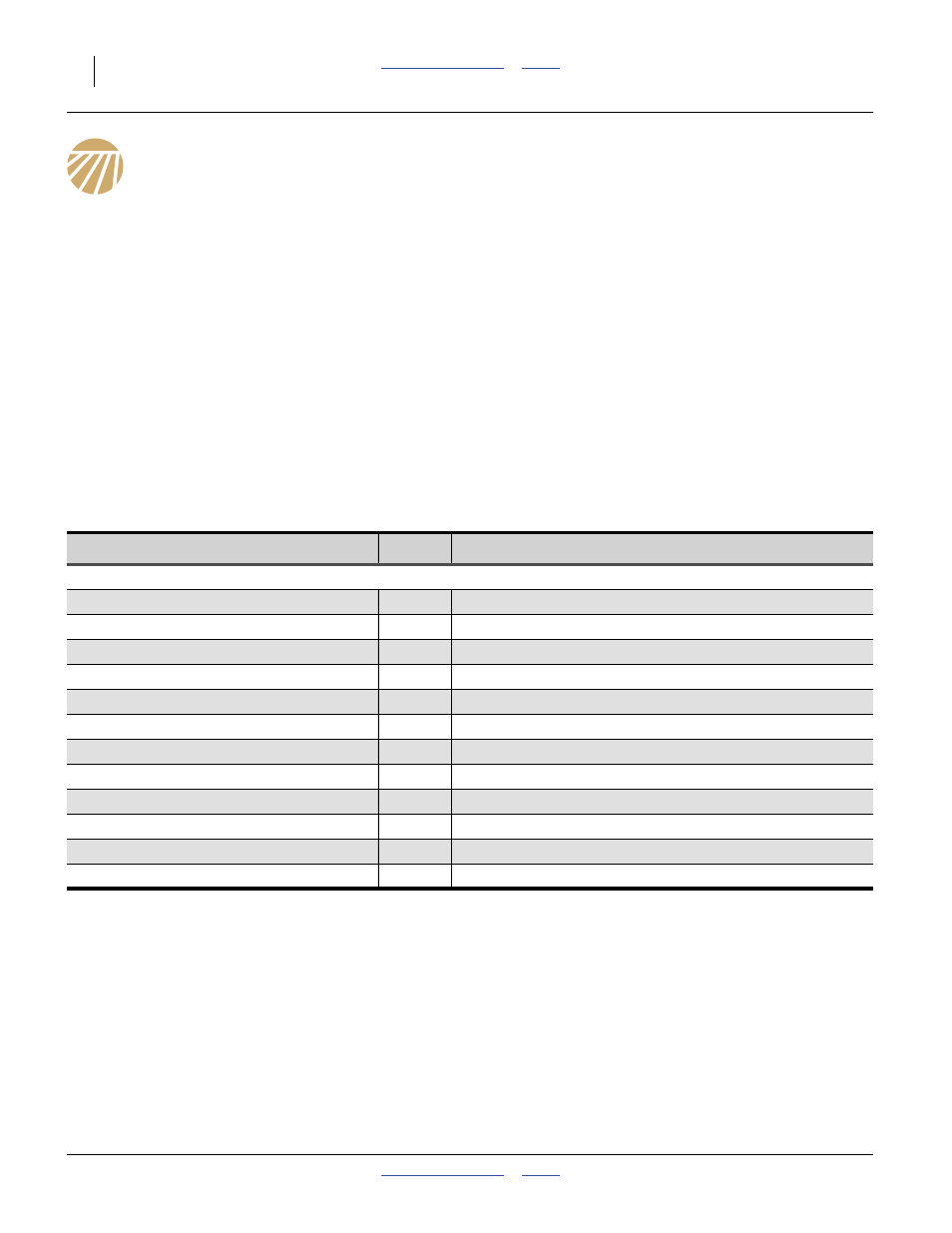

Adjustment

Page

The Adjustment Affects

Main Seed Box Rate

Drive Type

SRM

a

a. SRM: Seed Rate Manual: This adjustment is described in manual 118-794B.

Coarse seed rate

Rate Adjustment Handle

Fine seed rate

Seed Cup Doors

Consistent seed metering

Small Seeds Rate

Fine seed rate

3-Point Height

Compensate for unusual opener depths

Frame Level

Consistent seed depth

00 Series Row Unit Adjustments

Consistent seed depths in challenging conditions

Compensate for disc wear

Consistent seeding depth

Opener Depth (Press Wheel Height)

Primary control of seed depth

Furrow coverage behind seeding