6 maintenance overview, 7 overview of lubricating points – Great Plains P16867 Serial No 18009156 User Manual

Page 21

21

X-Press Trailing Kit

Operating Instructions

4.6 Maintenance Overview

After first operation

Instructions

Interval

Note

Check all screw, bolt and plug

connections

Check they are firmly seated. Tighten

/ Secure if necessary

---

---

Lubricate machine

See overview of lubricating points

---

Page 21

During operation

Lubricate machine

See overview of lubricating points

---

Page 21

Hydraulic system and

components (if applicable)

Check seals, signs of crushing/wear,

function and condition

daily

---

Parking Stand

Check condition and function

daily

---

After season

Lubricate machine

See overview of lubricating points

---

Page 21

Bolts

Grease any exposed threads

---

---

Entire machine

Carry out cleaning and maintenance

---

---

After 4 years

Hydraulic pipes (if applicable) Replace

MRL Anh I EN 1533

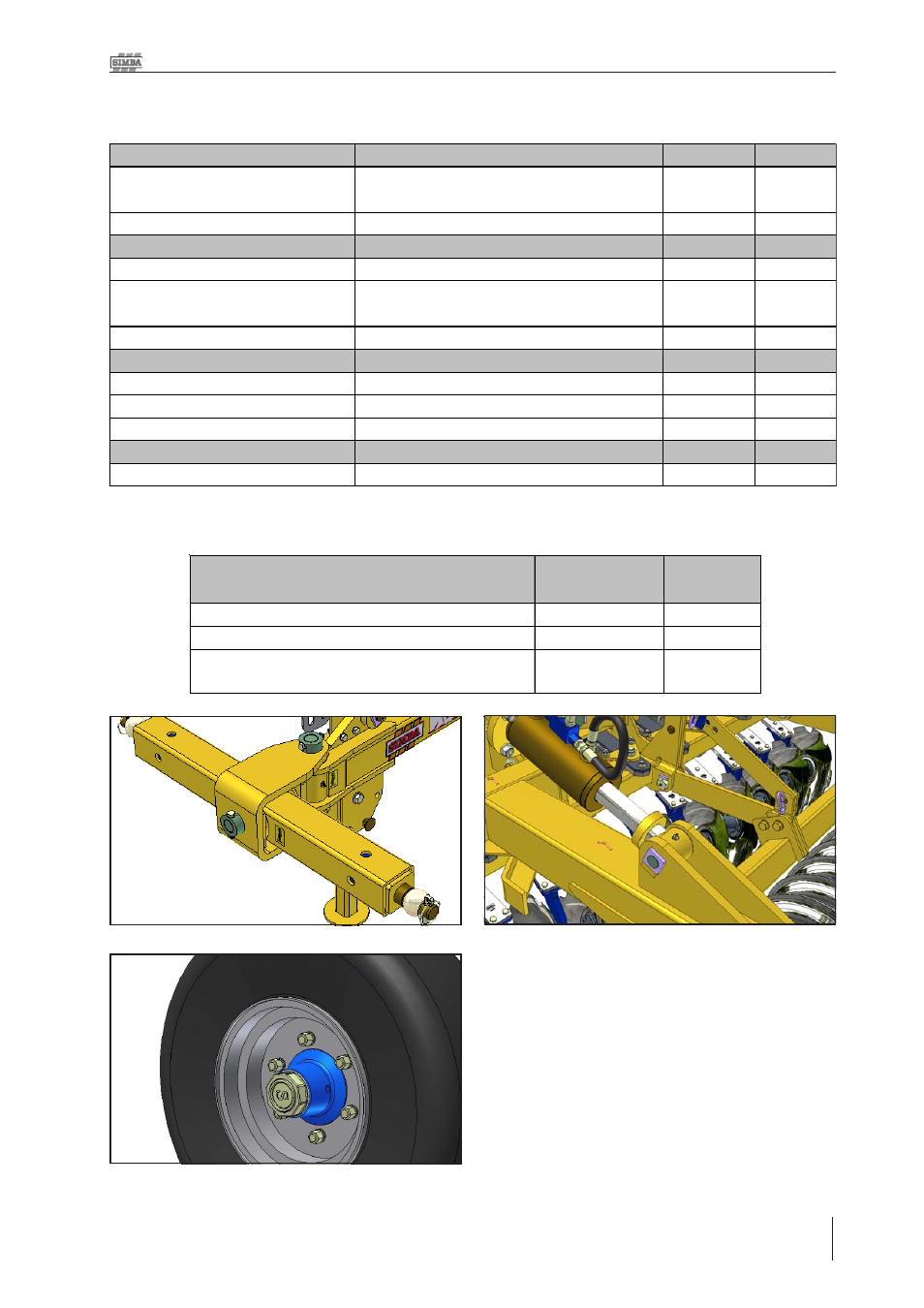

4.7 Overview of Lubricating Points

Linkage Pivots

50 hours

4.01

Transport Axle Cylinder / Optional Front Cyl.

50 hours

4.02

Wheel Hubs

(Note: on hubs w ithout nipples fitted hub

cap should be removed and hub packed w ith grease)

600 hours

4.03

X-Press Trailing Kit Lubrication Points

Interval

Diag. No.

Fig. 4.01: Bar Coupler Grease Points

Fig. 4.02: Lift Cylinder Grease Point

È

Fig. 4.03: Wheel Hub Grease Points

И

И

И

4. Servicing and Maintenance