3 adjusting depth, 2 work settings – Great Plains P16867 Serial No 18009156 User Manual

Page 18

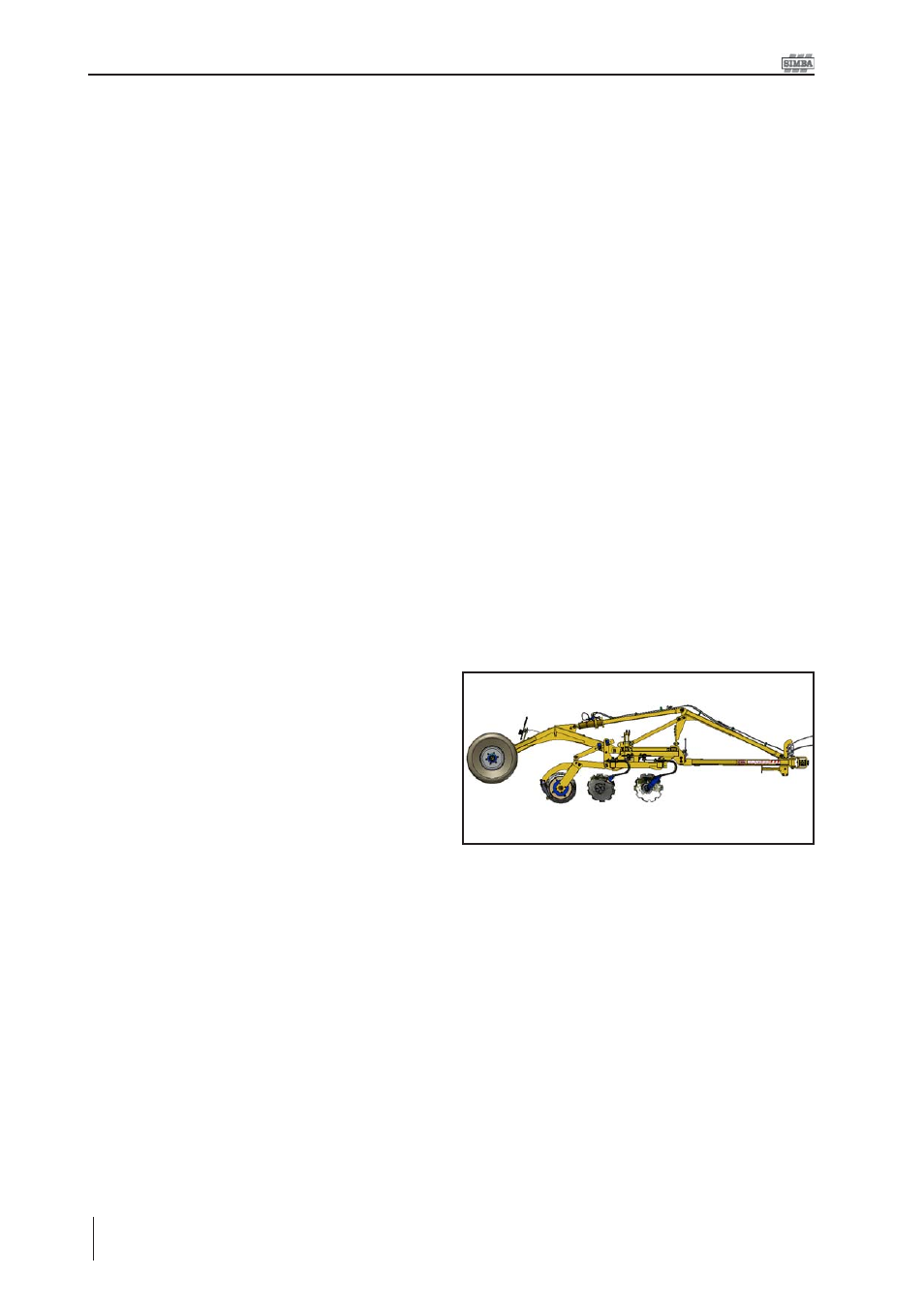

X-Press Trailing Kit

Operating Instructions

18

3.3 Adjusting Depth

Working depth is controlled using the tractor

linkage and the roll linkage.

Roll depth is controlled using the depth stops

and pins on the roll linkage. Reversing the

depth stop through 180° and refitting gives a

finer depth adjustment.

When the depth has been altered, lower the

machine into work and check operation. If

the depth change has been significant then

other setting could be affected. This could

be chassis pitch (front to rear) and disc angle

for the given depth.

A small amount of cultivation, eg. a 20 metre

run, should be carried out before altering

these settings to check whether they are now

suitable for the cultivation effect required.

These settings should be addressed

immediately to prevent too much work being

carried out.

3.2 Work Settings

The X-Press should be run with the chassis

level to slightly tail low. In practice it is possible

to use the X-Press on ground conditions that

are unsuitable to achieve the desired effect,

and it is usually possible to operate the DD

Light roll without regular blockage under such

unsuitable conditions, assuming that the roll

assemblies are tight, the scrapers correctly

adjusted and rings smooth. As such,

especially under wet conditions, it is advisable

to check on the cultivation effect of the X-

Press.

Optimum performance has been found to be

achieved when the DD Light roll rings have

worn away the painted finish leaving a smooth

shiny surface. When the DD Light rings are

new or rusty, soil may tend to pick up on the

surface and blockage may occur, this will

reduce when the rings are shiny again.

The X-Press should be lifted fully clear of the

ground onto the transport wheels for all

headland turns. Turning with the disc units or

roller on the ground could lead to damage of

these components.

I

n work machine will want to normally move to

the left due to the forces acting on the front

and rear gangs. This can be countered by

allowing the machine to be offset from the

tractor centre line by enabling the tractor

linkage to float sideways. This is done by

removing or loosening the linkage sway bars.

If the machine always moves to the left either:

a)

reduce the front gang angle to reduce

the forces acting on the front blades

which will move the machine towards

the centre or

b)

increase the angle on the rear blades

to increase the forces acting on them.

3. Adjustment / Operation

Fig. 3.02: X-Press with Trailing Kit in work position

The changes must be made with the finished

cultivation in mind. Increasing rear blade

angle could lead to blocking of the blades /

roller in some circumstances.

If the rear roller is not giving enough

consolidation the tractor linkage may be

raised slightly to transfer weight to the roller.

Alternatively, reducing forward speed will

allow the roller more time to consolidate the

ground.

If an optional front cylinder is fitted to the

machine this can be used to alter the front to

rear pitch of the machine.