Tooth angle, Spot implement, Disconnect/move leading chains – Great Plains FH6800HD Operator Manual User Manual

Page 41: Spot implement disconnect/move leading chains

Great Plains Manufacturing, Inc.

Appendix B - Initial Setup

37

04/28/2014

564-070M

Tooth Angle

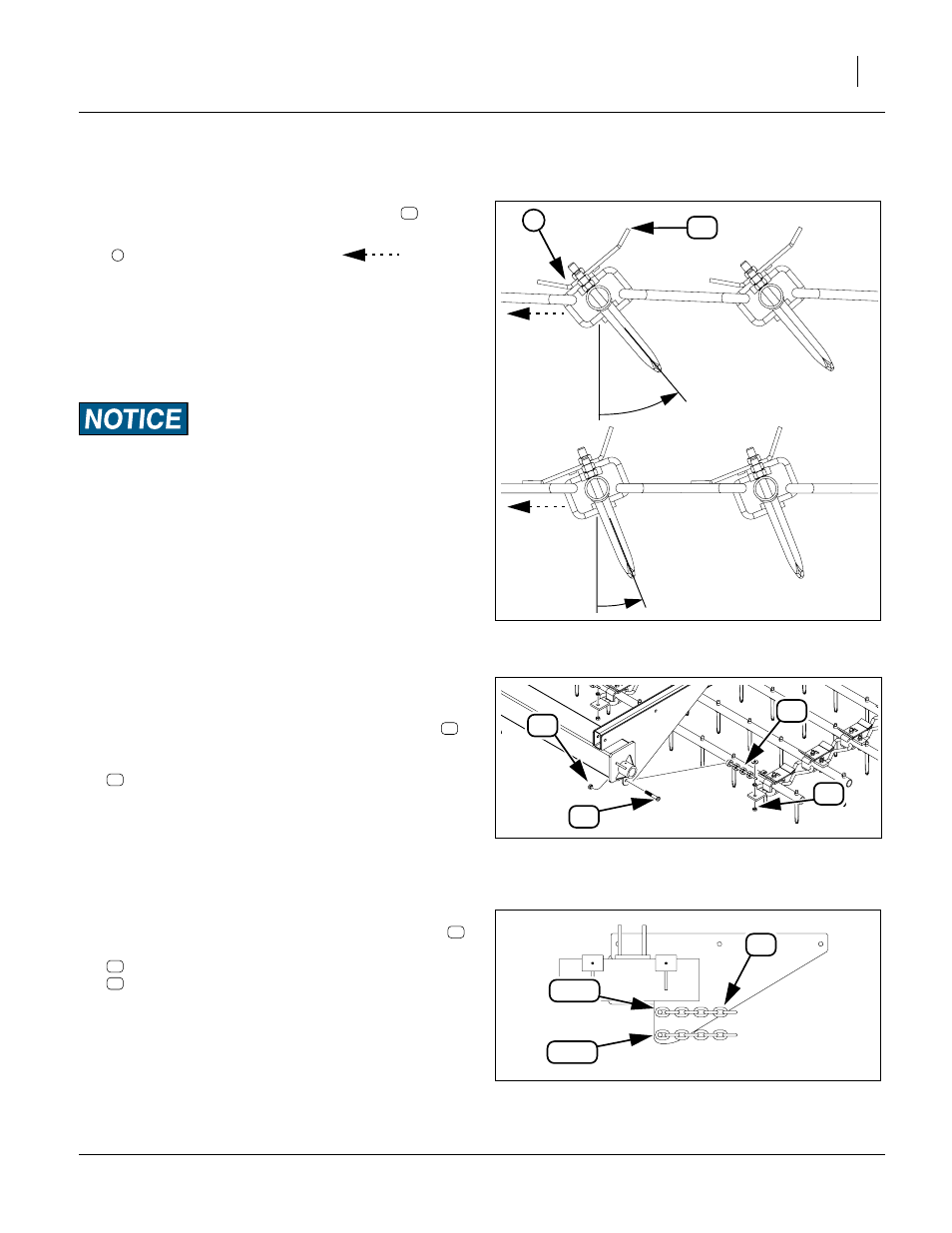

Refer to Figure 21

Tine tooth angle is set by the tooth angle plate

.

The tine teeth are factory-set with the sharp break

side

toward the direction of motion (

).

This pulls the teeth at 40

° off vertical (50° relative to the

ground). This angle is suitable for most conditions, has

no speed restrictions, usually creates a more optimal

seedbed, and provides easier residue flow.

For a more aggressive tine angle of 22

° off vertical (68°

relative to the ground), reverse all harrow sections at

their chain connection to the arms.

Excess Wear / Irregular Results Risks:

Do not exceed 4

1

⁄

2

mph (7.2 kph) with tines at 22

°.

Machine loads are much higher.

Tine sections may also hop on the ground.

To change tine angle:

Spot Implement

1.

With the harrow directly hitched to a tractor (not to

another implement), fully unfold the implement in

field conditions (page 16). Allow enough room for the

tractor to approach either end of the harrow sections.

Pull forward to lay the sections flat on the ground.

Disconnect/Move Leading Chains

Refer to Figure 22

2.

Disconnect the trailing end of the leading chains

from the harrow sections. Remove and save only the

lock nut:

803-019C NUT LOCK 1/2-13 PLT

Refer to Figure 22 and Figure 23

3.

Disconnect the leading ends of the leading chains

from the section frame. Remove fasteners:

802-722C HHCS 9/16-12X3 1/2 GR5 ZNYCR

803-319C NUT HEX TOP LOCK 9/16-12 ZNYCR

Re-attach them at the other frame hole.

Use the upper hole for the 22

° tooth angle.

Use the lower hole for the [standard] 40

° tooth angle.

Tighten nuts only until bolt does not rotate freely.

Figure 21

Tooth Angles

31746

1

38

40

°

22

°

38

Figure 22

Disconnect Leading Chain

31648

64

70

61

40

40

64

Figure 23

Relocate Leading Chain

31756

40

22

°

40

°

40

61

70