Air and seeding system overview – Great Plains YP825A3P Operator Manual User Manual

Page 32

28

YP4-6-825A3P

Great Plains Manufacturing, Inc.

401-652M

2013-05-28

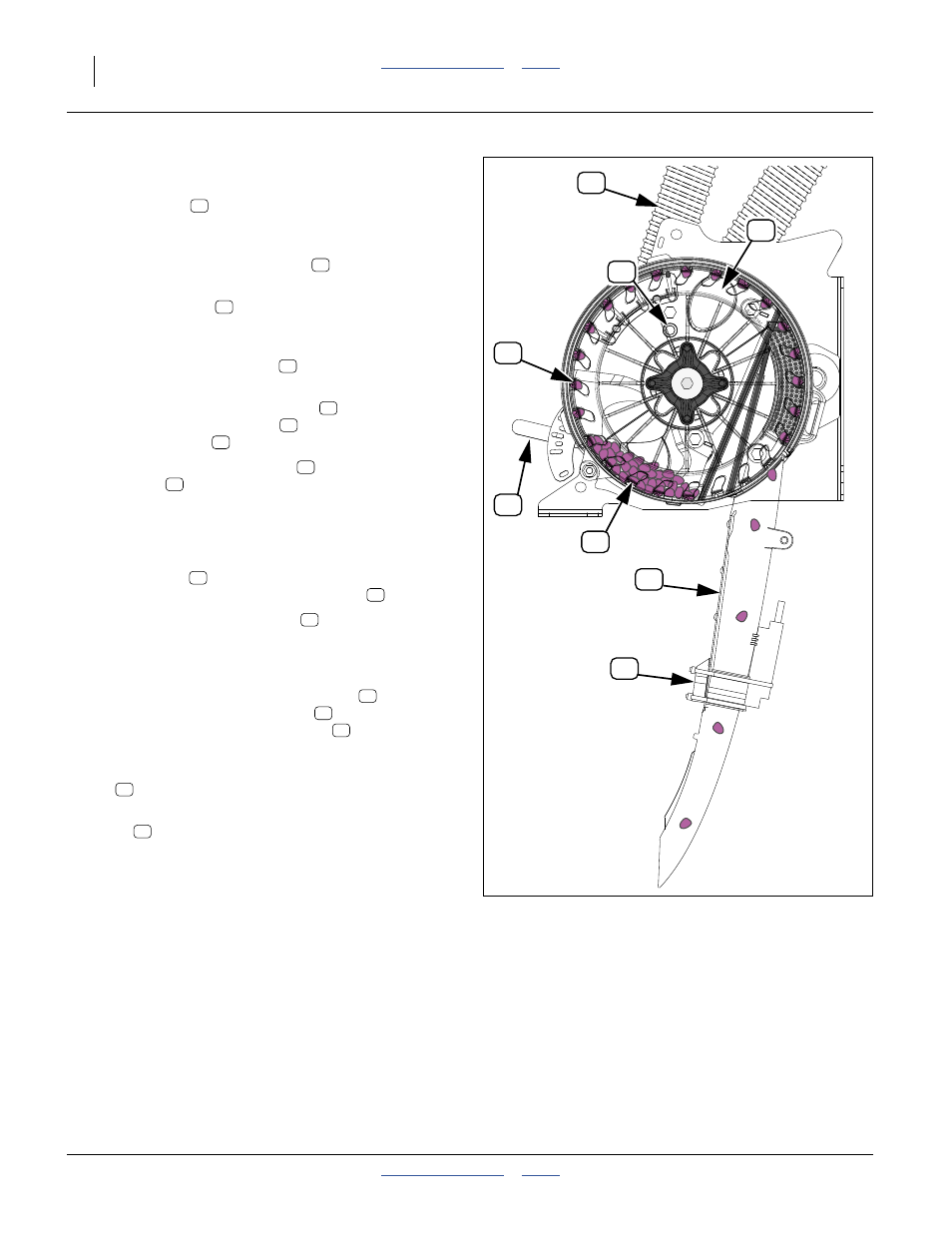

Air and Seeding System Overview

Refer to Figure 20, on page 27, and Figure 21.

The hydraulic fan

supplies air exclusively for meter

operation. Fan rpm is operator-adjusted (page 31),

normally via the tractor circuit’s hydraulic flow control.

A manually-adjusted butterfly valve

is provided at the

fan outlet. See page 31 for valve adjustment.

The manifold system

delivers fan air across the

planter. It includes passive internal design features to

balance pressure across the planter.

Separate pressurization tubes

route manifold air to

each row unit.

Seed is delivered from the seed box

by gravity

through the sliding seed tubes

Air-Pro

®

seed meter

.

A manually adjusted inlet shutter

controls the size of

the seed pool

at the base of the meter. The shutter

also minimizes air loss back up the seed inlet tube, and

is also used during row shut off. See page 55 for shutter

adjustments.

At the meter, pressurization air exits the meter through

the seed pockets

of the disk, and holds seed in the

pockets until released above the seed tube

.

In the seed tube, the seed sensor

detects passage of

seeds. Medium size and large seeds are counted

individually. With smaller seeds, most are detected,

allowing the monitor to detect stoppages.

Several rows have a pressure sensor port

for the

meter pressurization system. A line

from each of

these rows is connected to a chamber

to average the

pressures.

The averaged pressure is reported by a Magnehelic

®

gauge

visible to the tractor operator. See page 43 for

use of the gauge in making fan adjustments.

A sensor

in each seed tube reports seed passage to

the seed monitor. Larger seeds are counted individually.

For smaller seeds, the system acts as a blockage

monitor.

Note: Use of the special blank disk (page 59), and closing

the seed inlet shutter (page 55), are particularly

important when a sensor row is shut off.

Note: On any row, running a normal disk with no seed, or

with an open empty inlet, unbalances the air

system. Doing either at a sensor row causes the

gauge to mis-report as well.

Note: Do not operate in the ground with the fan shut off, or

with insufficient manifold pressure. The meters will

completely fill with seed. Meter clean-out may be

required to resume normal operation.

Figure 21

Air-Pro

®

Meter, Disk Side

31040

14

12

10

4

9

8

11

13

1

2

3

4

5

7

8

9

10

11

12

14

15

16

17