Monitor setup, Marker setup (option), Monitor setup marker setup (option) – Great Plains YP825A3P Operator Manual User Manual

Page 23

Great Plains Manufacturing, Inc.

Preparation and Setup

19

2013-05-28

401-652M

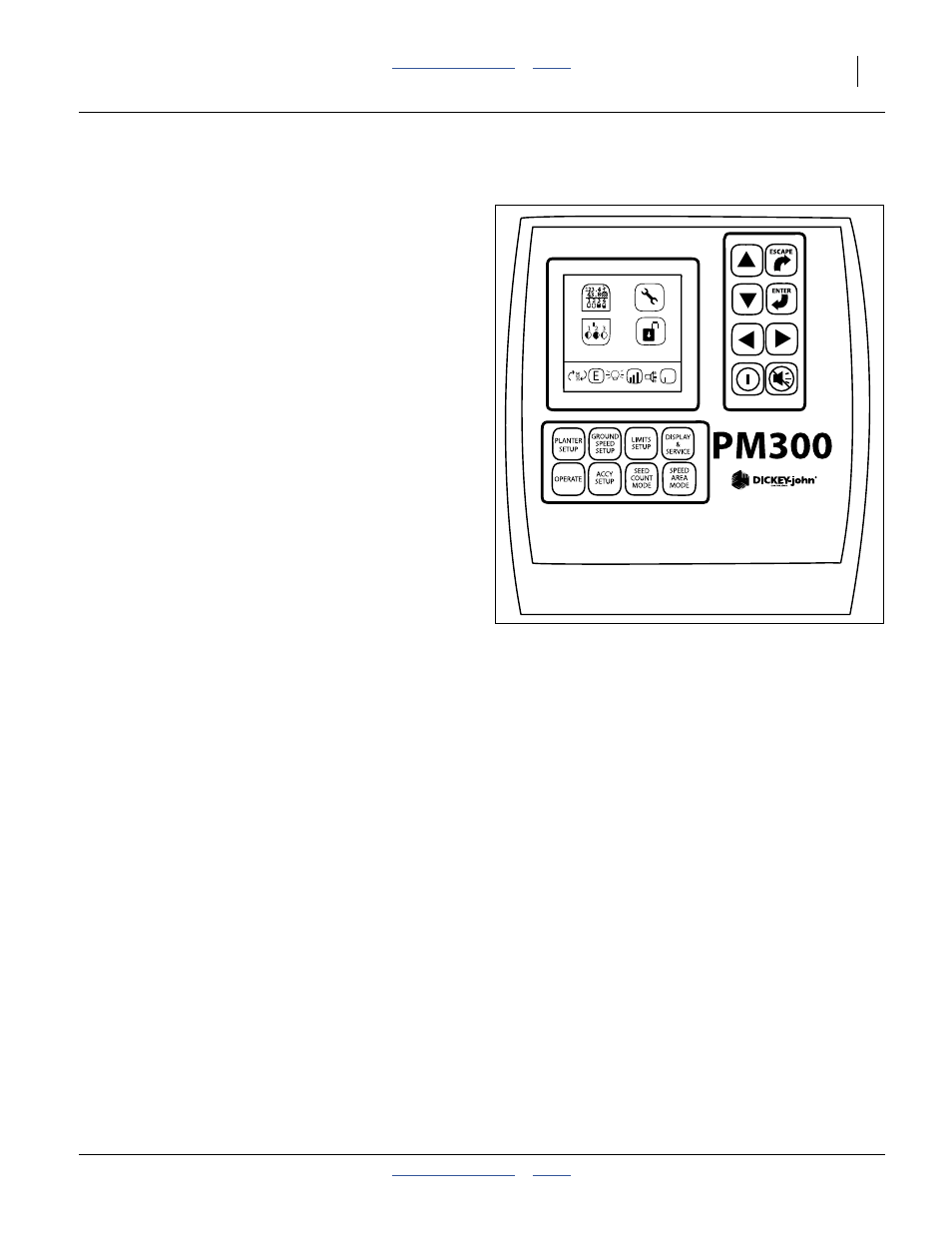

Monitor Setup

Refer to Figure 19

The standard DICKEY-john

®

PM300 system monitors

the following elements of a YP4-6-825A3P planter:

• Seeds at each row unit seed tube.

• Ground speed.

See “Seed Monitor Console Installation” on page 112.

Refer to the DICKEY-john

®

PM300/PM332/PM400

Operator’s Manual for monitor operations.

After installation, and prior to first field use, the monitor

must be setup with the row spacing and speed sensor

constant, as well as your preferences for information

display. Row count is auto-assigned, but any other

factory defaults are not likely to be correct for your

planter.

Row spacing data may be found in the Appendix.

For speed setup, Great Plains recommends using the

400-foot calibration described in the DICKEY-john

®

manual, rather than using a theoretical “# of pulses”.

Perform the calibration run in representative field

conditions, as soil conditions, surface looseness and

other tillage practices can cause variations in the

effective rolling radius of the ground drive wheel.

Prior to each planting session, set any desired limits for

speed and population for the current crop.

Marker Setup (Option)

Prior to first use, check and adjust:

• “Marker Speed Adjustment” on page 113.

Prior to first use, and whenever changing row spacings,

set or reset:

• “Marker Extension” on page 114.

Prior to each planting session, check and adjust:

• “Marker Disk Adjustment” on page 42.

Figure 12

Monitor Primary Screen

29971