Install press wheel assemblies, Engage ground drive spring, Rl f b – Great Plains YP825A3P Operator Manual User Manual

Page 115

Great Plains Manufacturing, Inc.

Appendix B - Pre-Delivery

111

2013-05-28

401-652M

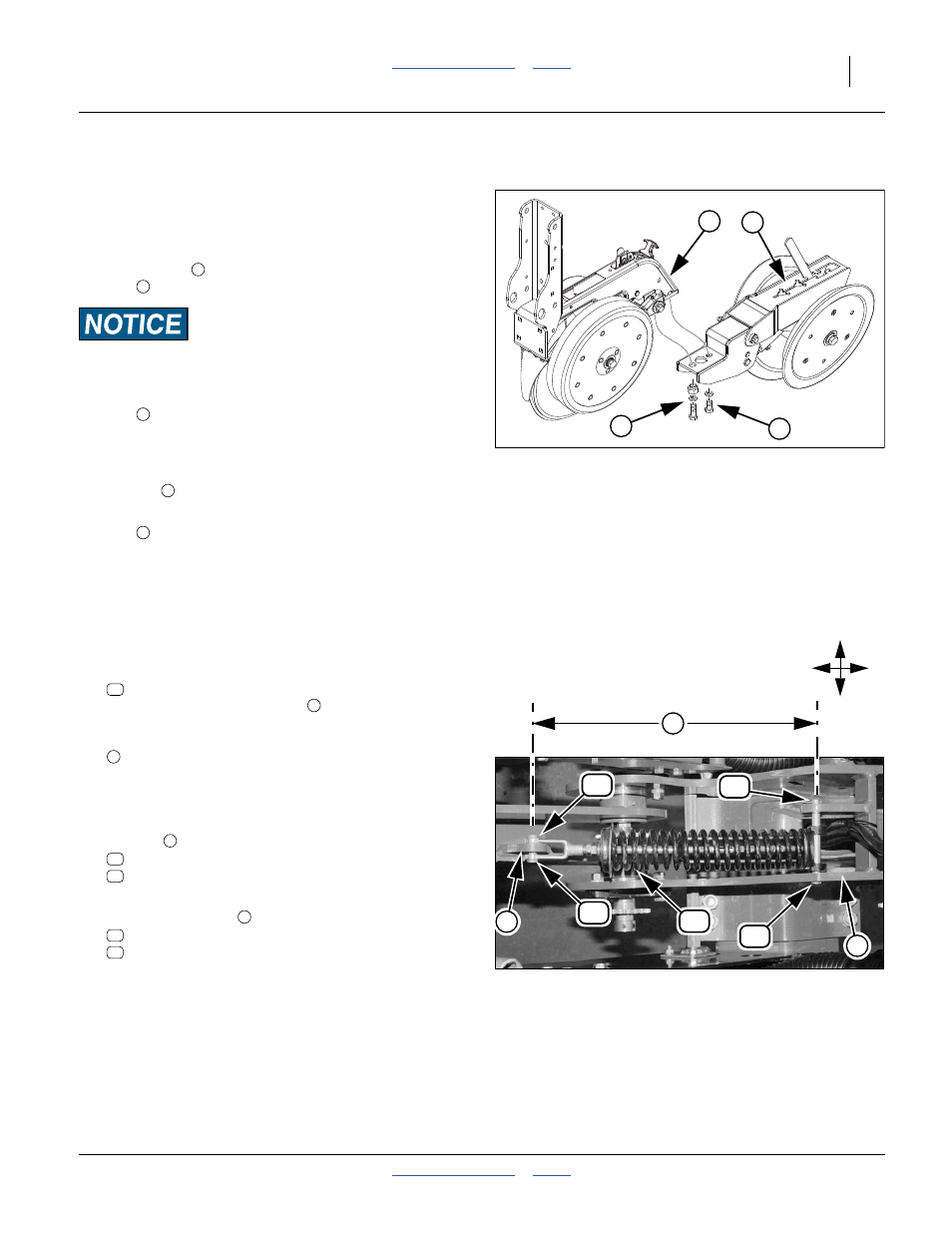

Install Press Wheel Assemblies

To meet highway clearance requirements, press wheel

arms and wheels may not be factory-installed.

Refer to Figure 96

4.

Remove and save the

1

⁄

2

-13x1 inch hex head bolt

and washer

at the back of an incomplete row

unit

.

There are four bolts at this location. Remove only the hex head

bolts. Do not loosen or remove the square head bolts forward.

5.

Remove and save the

1

⁄

2

-13

×

1

1

⁄

2

inch hex head

bolt

, washer, and eccentric adjuster nut.

6.

Align the

1

⁄

2

inch holes in the press wheel assembly

with the

1

⁄

2

-13 tapped holes in the row unit, loosely

assemble with the

1

⁄

2

-13

×

1 inch hex head bolt and

washer

.

7.

Loosely screw in the

1

⁄

2

-13

×

1

1

⁄

2

inch hex head

bolt

, washer, and eccentric adjuster nut. Rotate

the adjuster to visually align the press wheel

assembly with the row unit, and tight the adjust and

both bolts.

Engage Ground Drive Spring

8.

Select one new:

121-763S OPENER SPRING ROD ASSY. SHRT.

Check that the overall length

, from clevis to

trunnion, center-line to center-line, with pin holes

aligned, is:

17

1

⁄

4

inch

±

1

⁄

16

inch (43.7 to 44.0 cm)

9.

Remove and save all pins at clevis and trunnion

ends of spring rod assembly.

10. Secure the clevis end of the spring assembly to the

arm lug

, using one each:

805-127C PIN CLEVIS 1/2 X 1 3/4

and

805-064C PIN COTTER 7/64 X 1 LONG

11. Secure the trunnion end of the spring assembly to

the upper trunnion

, using one each:

805-235C PIN CLEVIS 1/2 X 5 PLATED

and

805-064C PIN COTTER 7/64 X 1 LONG

Figure 96

25AP Press Wheel Assembly

25383

1

2

4

3

2

3

4

2

4

Figure 97

Ground Drive Spring Rod

31038

6

5

R

L

F

B

57

59

58

60

58

7

57

5

59

58

60

58