Great Plains PT1230 AA1080 Operator Manual User Manual

Page 48

46

Section 5 Maintenance and Lubrication

PT1230 Pull-Type Folding Planter 401-069M-B

4/12/05

Great Plains Mfg., Inc.

2.

Inspect belt. Replace belt if necessary.

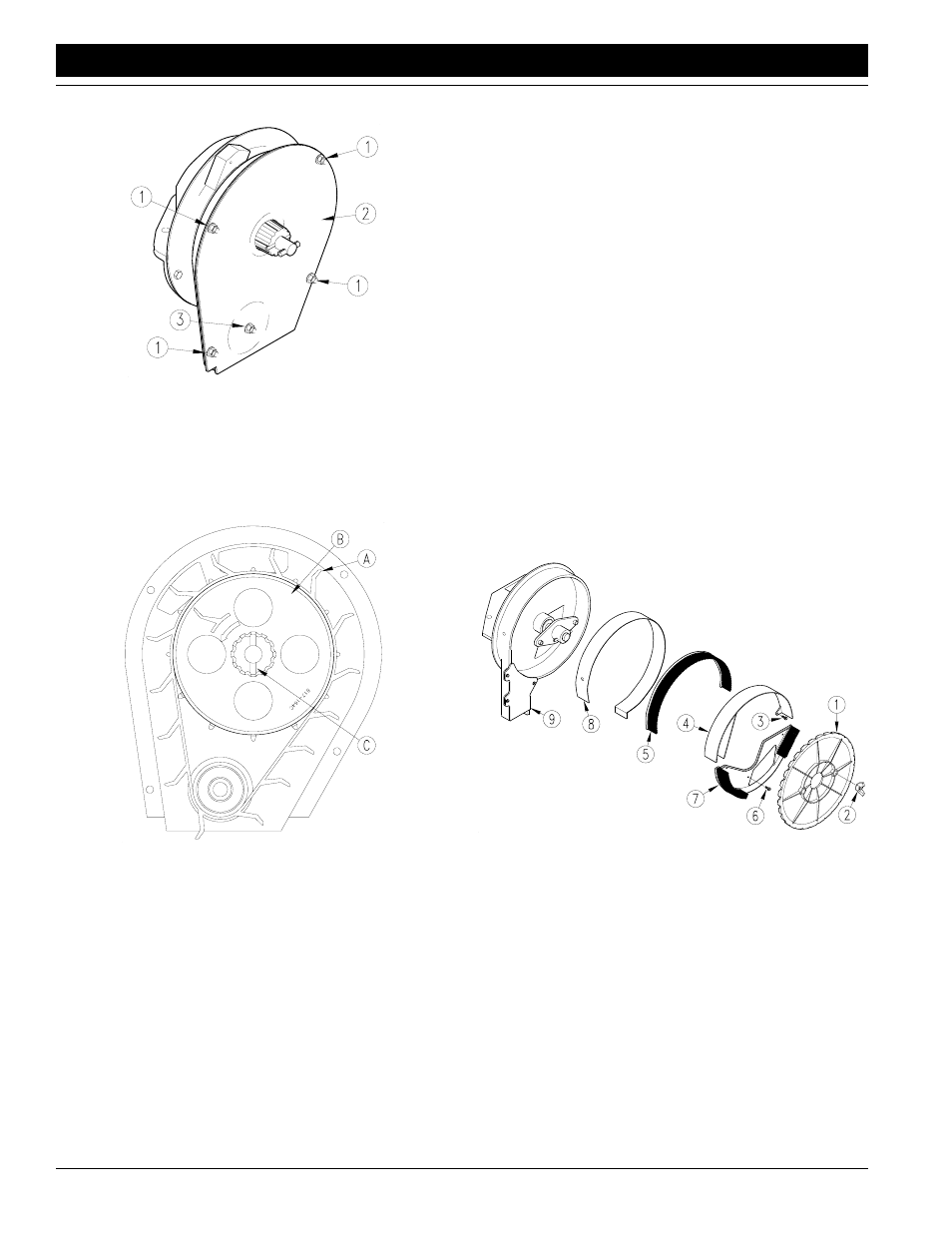

Figure 5-11

Belt Inspection

3.

To replace a worn or broken belt, refer to Figure 5-12.

Be certain paddles (A) are oriented as shown. Belt

drive wheel (B) may be removed by removing spring

pins (C).

Figure 5-12

Belt Installation

4.

Reassemble meter in reverse order.

Brush-Type Meter

Inspect brush meters daily for buildup of foreign material

on seed disk, particularly in seed-loading slots.

Remove seed disk (1) by removing two wing nuts (2). See

Figure 5-13. Wash seed disk with soap and water. Use

compressed air to clean any cracked seed, hulls, etc. from

brush areas of meter housing.

14966

15049

Before storing brush meters:

1.

Remove brush meter from seed hopper by removing

two bolts and nuts that secure meter to hopper.

2.

Remove seed disk (1) by removing two wing nuts (2).

3.

Wash seed disk with soap and water.

4.

Unscrew three hex-head screws (3) from brush holder

(4) and remove brush holder and retaining brush (5).

5.

Unscrew three hex-head screws (6) from lower brush

(7) and remove brush and wear band (8).

6.

Wash all parts including meter housing (9) with soap

and water. Dry thoroughly.

7.

Reassemble brush meter except for seed disk. To in-

stall retaining brush (5), first position brush making

sure base of brush is tight against bottom of meter

housing. Install brush holder (4) and three hex head

screws (3). Tighten center screw first, then left screw

and right screw last.

8.

Inspect seed disc for wear. To measure for wear, lay a

straight edge across disk surface. Measure gap be-

tween disk and straight edge. If measurement is

greater than 0.075 inch, replace seed disk before next

planting season.

9.

Store brush meter and seed disk in a clean, dry place.

Figure 5-13

Brush Meter

Opener Disks, Scrapers and Gauge Wheels

1.

Lift side gauge wheel off ground. Move tire in and out

to check for end play. Check for roughness in bearing

by rotating wheel. If the bearings are rough, inspect

and replace if necessary.

2.

Remove side gauge wheels from arms to access

opener disks and scrapers.

15869