Depth stop & angle gauge – Great Plains 1500TM Assembly Manual User Manual

Page 15

Great Plains Manufacturing, Inc.

Assembly

11

12/12/2013

586-535Q-ENG

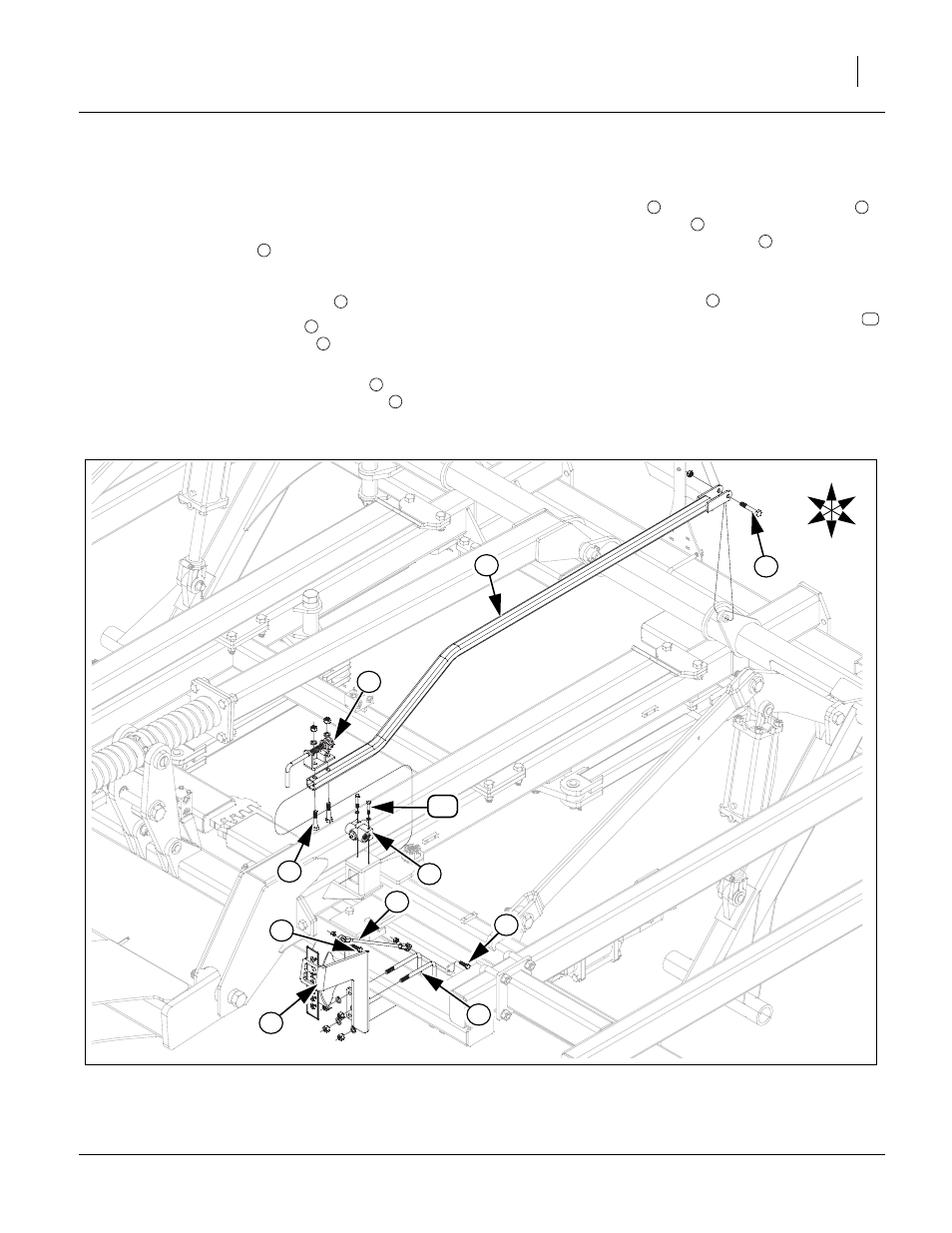

Depth Stop & Angle Gauge

Refer to Figure 9

Note: See machine layout drawings in Appendix for

proper gang gauge placement for each model.

31. Slide depth stop tube

from rear of machine

through square hole on depth control bracket on cen-

ter wing frame. Align rear holes over lever on torque

tube, secure with 1/2 x 3 hex bolt

, 1/2 top lock nut.

32. Fasten depth stop assembly

on top of depth stop

tube with 1/2 x 2 1/2 hex bolts

, 1/2 lock washers

and nuts.

33. Attach angle gauge bracket assembly

to front of

center frame with 1/2 x 3 1/32 x 6 u-bolts

, 1/2 lock

washers and 1/2 nuts.

34. Attach gauge link

to gauge bracket assembly

with 3/4 x 1 1/4 hex bolt

and 3/8 top lock nut, Do

not attach other end of gauge link

until gang

assemblies are installed, See “Center Gang Bar” on

page 14,

35. Attach depth control valve

to top of depth stop

bracket (plunger forward), with 5/16 x 2 hex bolts

and 5/16 lock washers.

36. Tighten all bolts with lock nuts snug, but do not

torque. The rest of the bolts may be tightened to

specs, See “Torque Values Chart” on page 24.

1

2

3

4

5

6

7

5

8

7

9

10

Figure 9

Depth Stop & Angle Gauge

43136

U

D

F

B

L

R

5

6

4

3

1

2

7

9

8

8

10