Set initial extension, Close-out, Marker operation – Great Plains YP925TD Assembly Instructions User Manual

Page 20: Marker maintenance, Appendix, Hydraulic connector identification, Ue at “ set initial extension

20

Flat Fold Marker

Great Plains Mfg., Inc.

113-870M

2012-22-03

Set Initial Extension

118. Set the approximate initial marker extension per the

instructions in the Operator manual. Because the

implement is typically not into the ground at this

time, the setting is approximate.

Close-Out

119. Lubricate markers. Pump grease at all grease zerks

until grease emerges.

120. Fold the markers.

Marker Operation

Marker operation is covered in the planter Operator

manual.

Marker Maintenance

Marker maintenance is covered in the planter Operator

manual.

Appendix

Hydraulic Connector Identification

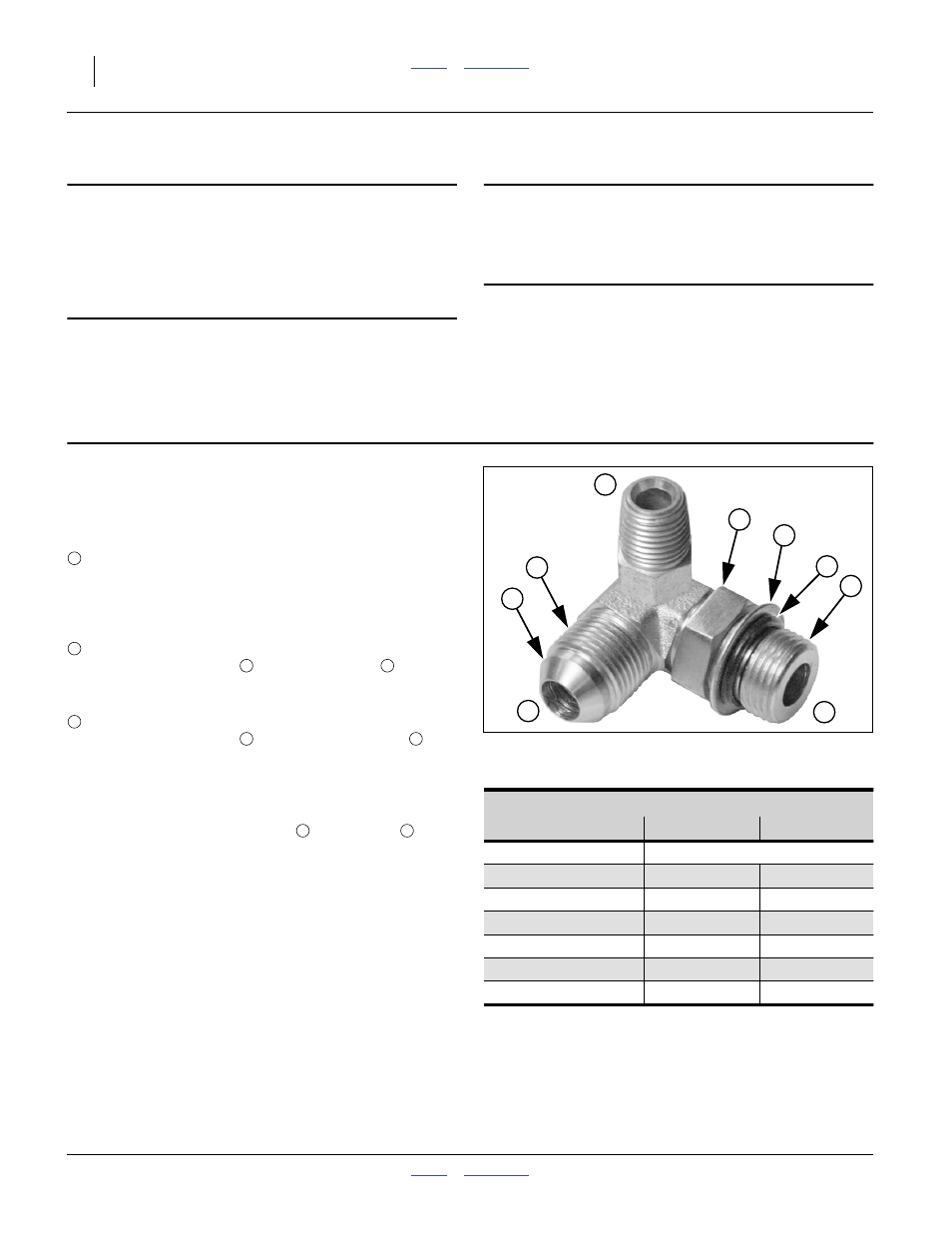

Refer to Figure 27 (a hypothetical fitting)

Leave any protective caps in place until immediately prior

to making a connection.

NPT - National Pipe Thread

Note tapered threads, no cone/flare, and no O-ring.

Apply PTFE

a

liquid or paste pipe sealant for hydraulic

applications (do not use tape sealant, which can foul

filters).

a PTFE: polytetrafluoroethylene, such as DUPONT

®

Teflon

®

.

Great Plains recommends RectorSeal

®

No.5

®

, available in

1

⁄

2

pint (236 ml) cans as part number 891-231C.

JIC - Joint Industry Conference (SAE J514)

Note straight threads

and the 37

° cone on

“M” fittings (or 37

° flare on “F” fittings). Use no

sealants (tape or liquid) on JIC fittings.

ORB - O-Ring Boss (SAE J514)

Note straight threads

and elastomer O-ring

.

Prior to installation, to prevent abrasion during

tightening, lubricate O-ring with clean hydraulic fluid.

Use no sealants (tape or liquid) on JIC fittings.

ORB fittings that need orientation, such as the ell

depicted, also have a washer

and jam nut

(“adjustable thread port stud”). Back jam nut away

from washer. Thread fitting into receptacle until

O-ring contacts seat. Unscrew fitting to desired

orientation. Tighten jam nut to torque specification.

2

5

4

9

8

7

5

3

Figure 27

Hydraulic Connector Ports

31282

Fittings Torque Values

Fitting

Ft-Lbs

N-m

1

⁄

4

NPT

1.5-3.0 turns past finger tight

9

⁄

16

JIC

18-20

24-27

9

⁄

16

ORB w/jam nut

12-16

16-22

9

⁄

16

ORB straight

18-24

24-32

3

⁄

4

JIC

27-39

37-53

3

⁄

4

ORB w/jam nut

20-30

27-41

3

⁄

4

ORB straight

27-43

37-58

1

1

2

4

5

3

5

7

8

9