Closeout, Setup, Appendix – Great Plains 3S-3000 Installation Instructions User Manual

Page 21: Torque values, Current manuals, Connector identification, 21 setup, 21 appendix, 21 current manuals, Current manuals connector identification

Great Plains Mfg., Inc.

Closeout

21

09/05/2012

194-149M

Closeout

130. Connect the drill to the tractor or other hydraulic

power source.

131. Perform the Opener Lift Bleeding steps from your

updated drill Operator manual.

132. Clean any excess hydraulic fluid from all new con-

nections.

133. Remove lift locks and cycle the lift system several

times. Use a sheet of cardboard to check for leaks

at all new connections.

Setup

134. Initial setup for the opener down-pressure system is

found in the updated Operator manual. Check the

Setup, Operations and Adjustments sections. The

topic may be titled “Open Center” or “Non-Active

Hydraulic” systems.

135. Review Operations information prior to first use of

the updated drill.

136. Raise and fold the drill. Install any lift and transport

locks.

Appendix

Torque Values

Current Manuals

Connector Identification

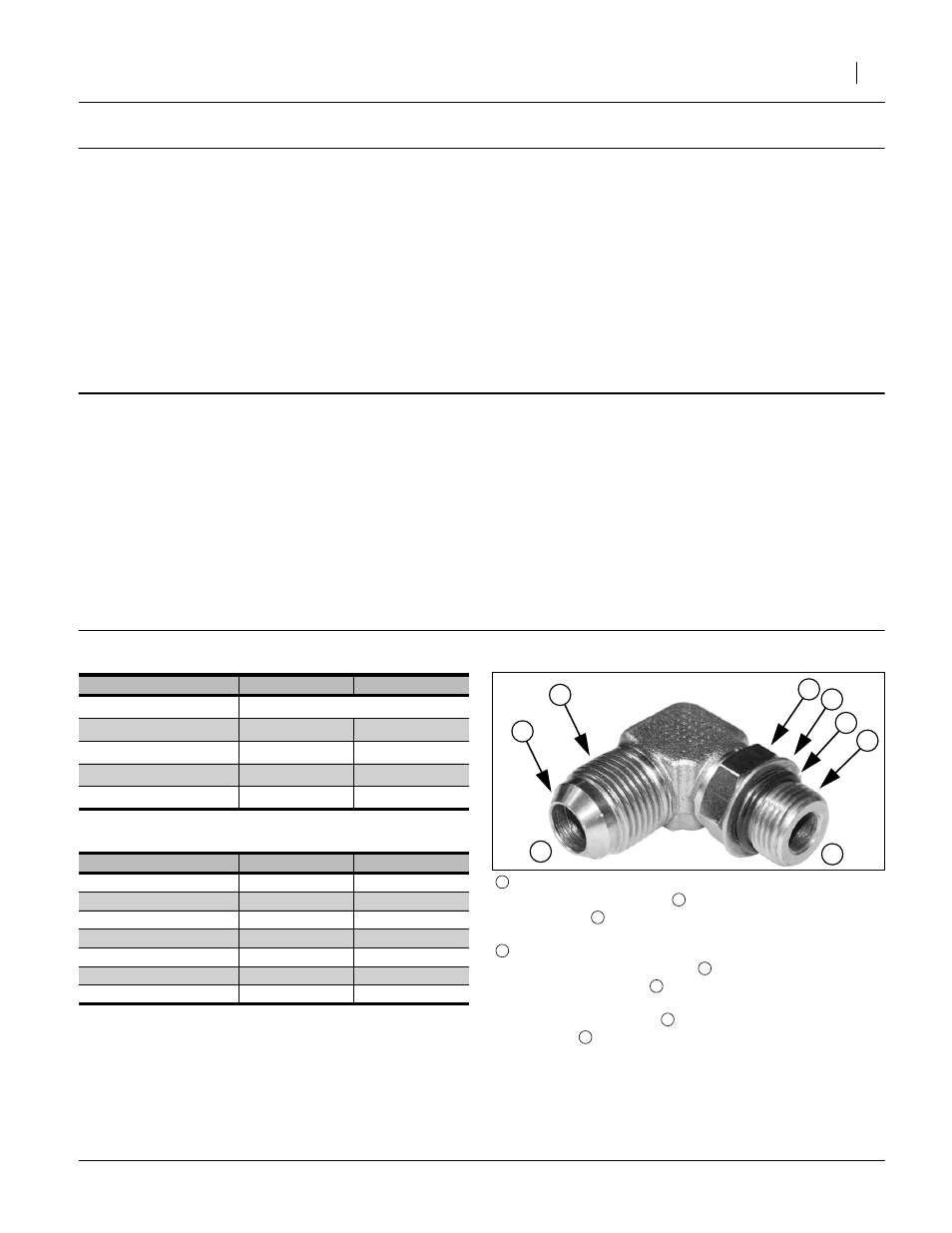

JIC - Joint Industry Conference (SAE J514)

Note straight threads

and the

37

° cone

on “M” fittings (or 37

° flare on “F”).

ORB - O-Ring Boss (SAE J514)

Note the straight threads

and,

elastomer O-Ring

.

Fittings needing orientation, such as the ell above,

also have a washer

and

jam nut

(“adjustable thread port stud”)

-

NPT - National Pipe Thread (not shown)

have tapered threads, no cone/flare, no O-ring.

Fastener/Fitting

Ft-Lbs

N-m

1

⁄

4

NPT

1.5-3.0 turns past finger tight

1

⁄

4

-20 GR5

8

11

9

⁄

16

JIC

18-20

24-27

9

⁄

16

ORB w/jam nut

12-16

16-22

9

⁄

16

ORB straight

18-24

24-32

Drill Model

Operator

Parts

2S-2600 DD1161-

195-200M-A

195-200P

2S-2600 DD1162+

195-200M-A

195-200P

2S-2600HD

195-069M

195-069P

3S-3000

195-110M-A

195-110P

3S-3000HD

195-068M

195-068P

3S-4000

195-242M-A

195-242P

3S-4000HD

195-067M

195-067P

25188

1

3

2

8

7

6

5

4