2s dd1161- check valve installation, These gauges are re-installed at step 60, Step 59. note which hose is which (b – Great Plains 3S-3000 Installation Instructions User Manual

Page 10

Great Plains Mfg., Inc.

10

Open Center Hydraulic Kit

194-149M

09/05/2012

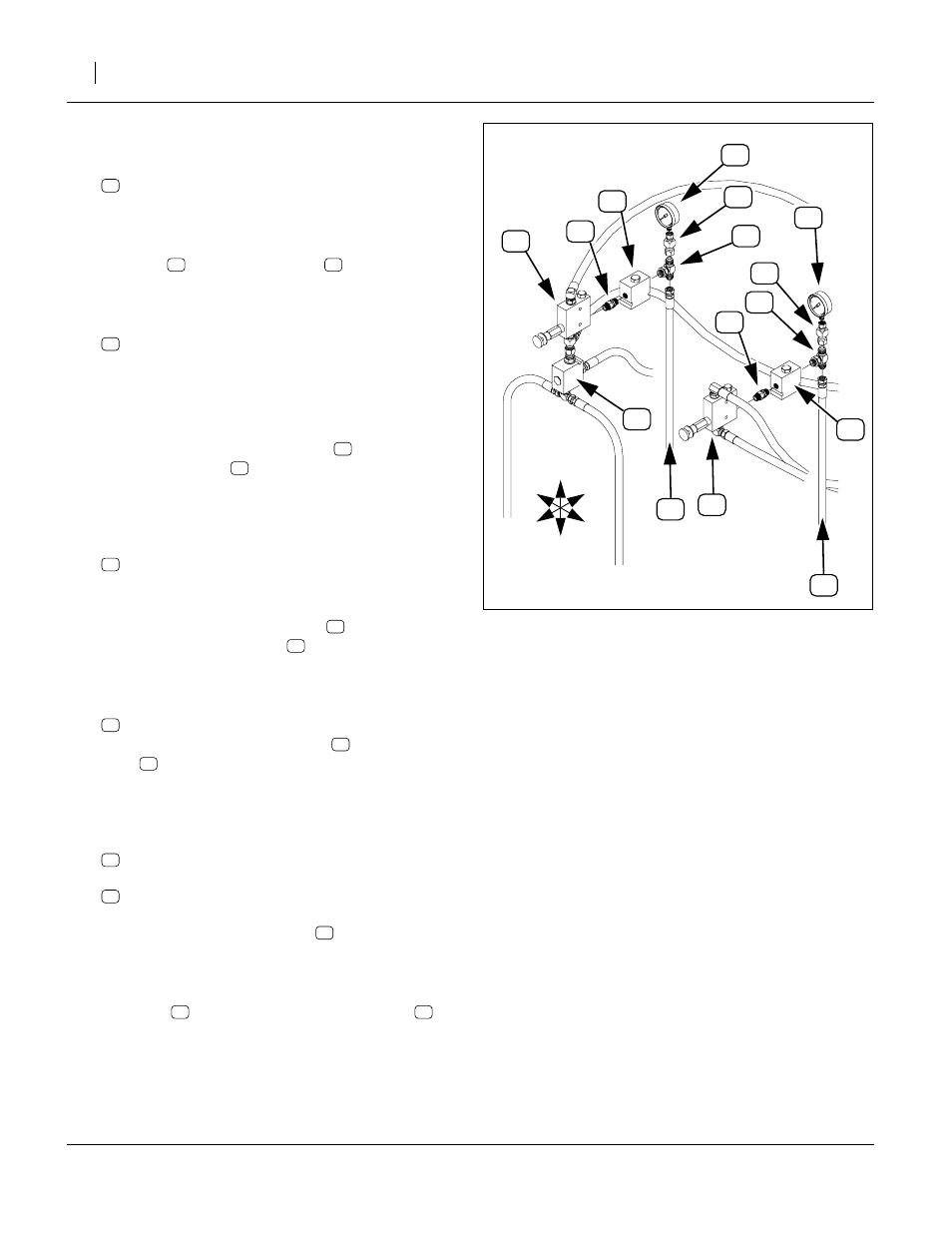

2S DD1161- Check Valve Installation

Refer to Figure 11

53. Select two new:

811-636C AD 9/16MORB STRAIGHT UNION

Make sure the jam nut is fully threaded onto the

adaptor.

54. At the lower rear valve Port R of each pressure con-

trol valve

, screw in the union

integral hex nut (NOT the end with the jam nut).

Tighten to 9/16ORB specification.

55. Select two new:

810-343C VALVE PO CHECK 2:1 W/9/16FORB

Note: These valves are stamped

85050146

, and if

shaken gently, do not rattle.

(The third valve, assembled at step 62, is a shuttle

valve, and does rattle.)

56. Screw Port 2 of each check valve

onto the other

end of the adaptor

installed at step 54. Turn until

finger tight, then back off until the side of the valve

with the hex head cartridge is Up and Port 3 is

down. Tighten the jam nut to 9/16ORB specification.

57. Select two new:

811-439C TE 9/16MORB 9/16MJIC 9/16MJIC

This is the symmetrical MJIC/MORB tee. There are

four of these in the kit.

58. Screw the MORB port of the tee

Port 1 of each check valve

. Screw until finger

tight, then back off until the JIC ports are vertical.

Tighten the ORB jam nut to 9/16ORB specification.

59. Locate the disconnected hoses:

At the lower port of each new tee

, reconnect the

hose

to the cylinder base ends that was discon-

nected at step 51. Do not use pipe thread sealant

on these or any JIC fittings. Tighten to 9/16JIC

specification (see page 21).

60. Select two new NPT swivel adaptors:

and the saved gauges:

810-300C PRESSURE GAUGE 3000 PSI

Apply liquid pipe thread sealant to the gauge MNPT

threads and screw the adaptor

Tighten to 1/4NPT torque specification (see

page 21).

61. At each valve, screw the JIC end of the gauge

assembly

onto the top port of the new tee

Orient the gauge to face forward, and tighten the

JIC connection to JIC torque specification.

WING

CENTER

BASE END

, CENTER OPENERS

BASE END

, WING OPENERS

1200

120

0

600

600

0

0

3000

3000

1800

1800

2400

2400

psi

psi

ROD END

, CENTER OPENERS

ROD END

, WING OPENERS

P

G

T

R

1

2

3

R

G

P

T

1

3

2

2

3

1

P.O. CHECK

Figure 11

Install 2S DD1161- Check Valves

18761

U

D

F

B

L

R

20