Collect a treatment sample, Calculate the treatment rate – Great Plains YP1630F-1670 Material Rate User Manual

Page 31

Great Plains Manufacturing, Inc.

Treatment Rate (Option)

29

2012-12-04

401-832B

10. Weigh the empty plastic bags. Record this number

for use at step 22. The sum of these weights is the:

BagWeights

Collect A Treatment Sample

Refer to Figure 15 on page 28

11. At the sampling rows identified in step 3, wearing

suitable protective equipment, remove the

diffuser

12. Securely attach an empty plastic bag to the tube.

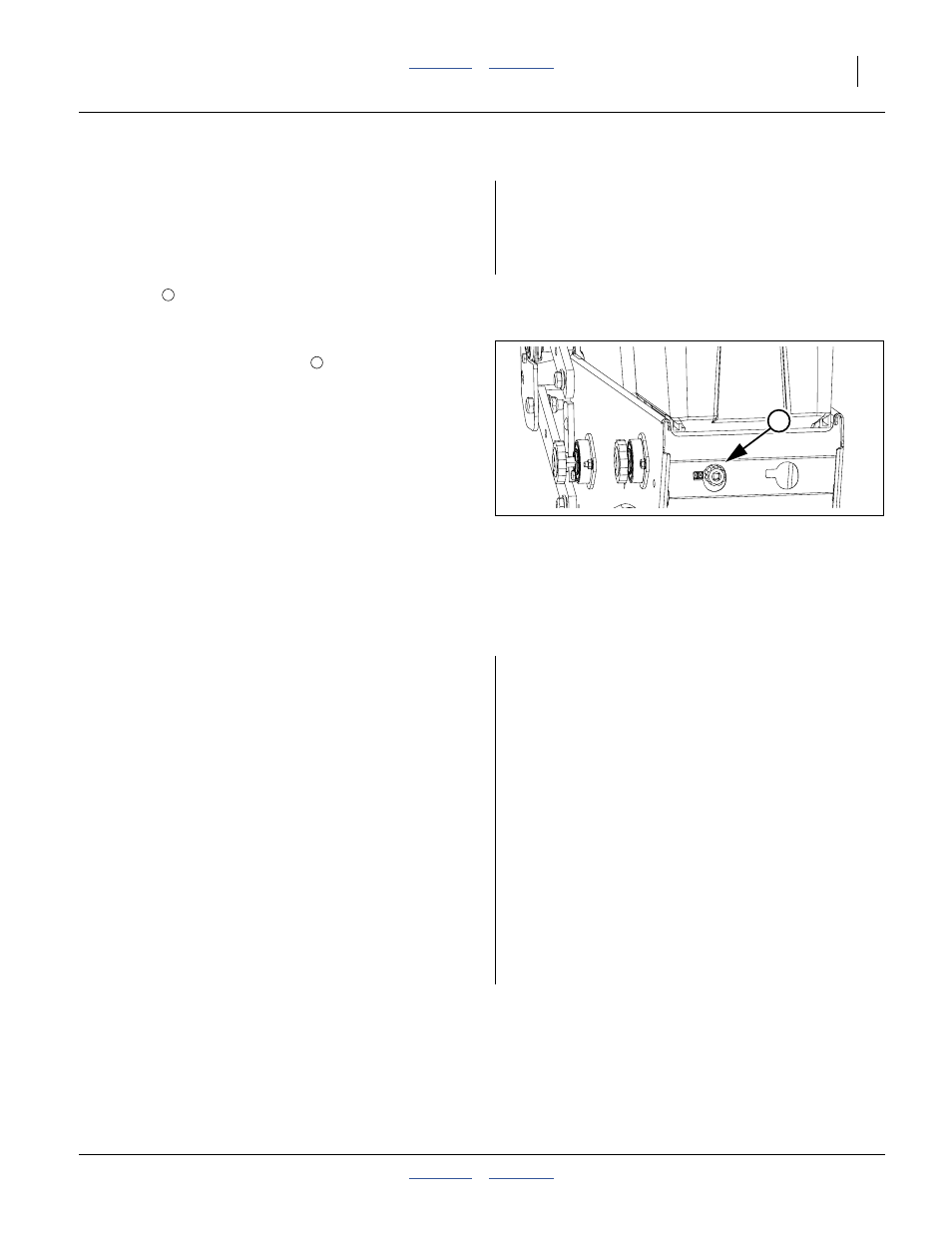

Refer to Figure 16

13. Set the treatment meter dials

from the charts, or the

NextDial

setting to be sampled.

Make a note of this setting, as it is needed in

calculations.

14. Start the tractor. Accelerate briskly to field speed.

Stop at the end of the course.

15. Set the dials to “00” on the sampled rows, to prevent

further material from dribbling into the sample bags.

16. Wearing suitable protective equipment, remove,

weigh and record the weight of the sample bags.

Empty each bag back into its hopper.

Calculate the Treatment Rate

The examples used are based on the application

example data from page 27, and the empty bag weights

from step 10.

17. Remove and weigh all the sample bags. This is the:

GrossWeight

18. Determine net weight of metered material.

19. Determine the net weight per row:

20. Use a scaling factor to determine the

TestRate

:

70 cm Hectare scaling factor: 14.29

×

30 inch Acre scaling factor:

17.42

×

21. Determine the percent deviation (a correction factor):

22. Use the correction factor to determine the next dial

setting to test:

23. If the deviation is less than 1.5%, or within your own

allowable tolerances, calibration is complete.

Otherwise, run another test, using the calculated

NextDial

setting, starting at step 12.

Metric Example:

USc Example:

SampleCount

(number of rows to sample):

3

3

Empty sample

BagWeights

:

0.010 kg (10 grams)

0.022 lbs

Note: If any material flowed, then stopped, when setting

the dials, return that material to the hopper, then

re-secure the bag.

Figure 16

Treatment Meter Dial

34452

Metric Example:

USc Example:

GrossWeight

:

2.854 kg

2.109 lb.

TotalNetWeight

:

2.854 - 0.010

= 2.844 kg

2.109 - 0.022

= 2.087 lb

RowNetWeight

:

2.844

÷ 3

= 0.948 kg

2.087

÷ 3

= 0.696 lb

TestRate

:

0.948

× 14.29

= 13.5 kg/ha

0.696

× 17.42

= 12.1 lb/ac

Deviation

:

13.5

÷ 12.8

= 0.94 (94%, 6% high)

12.1

÷ 11.4

= 0.94 (94%, 6% high)

NextDial

:

52

Ч 0.94

= 49

52

Ч 0.94

= 49

TotalN etWeight

GrossWeight

BagWeights

–

=

RowNetWeight

TotalNetWeight

SampleCount

----------------------------------------

=

TestRate

RowNetWeight

ScalingFactor

×

=

Deviation

TargetRate

TestRate

---------------------------

=

NextDial

PriorDial

Deviation

Ч

=