Treatment rate (option) – Great Plains YP1630F-1670 Material Rate User Manual

Page 28

26

Great Plains Manufacturing, Inc.

YP1630F

401-832B

2012-12-04

Treatment Rate (Option)

This section covers application of granular dry

treatments using the optional on-row treatment hoppers.

Treatments may include insecticide, herbicide and other

small granular or pelletized materials.

Agricultural Chemical Hazard:

Follow all chemical supplier precautions for handling

treatments. Wear protective equipment prescribed for the

current material, and for all previous materials used since

last thorough hopper clean-out. Read and follow material

label directions. Obtain and retain MSDS

a

information for the

present and recent materials. Many treatments are extremely

hazardous and can cause disabling or fatal injury.

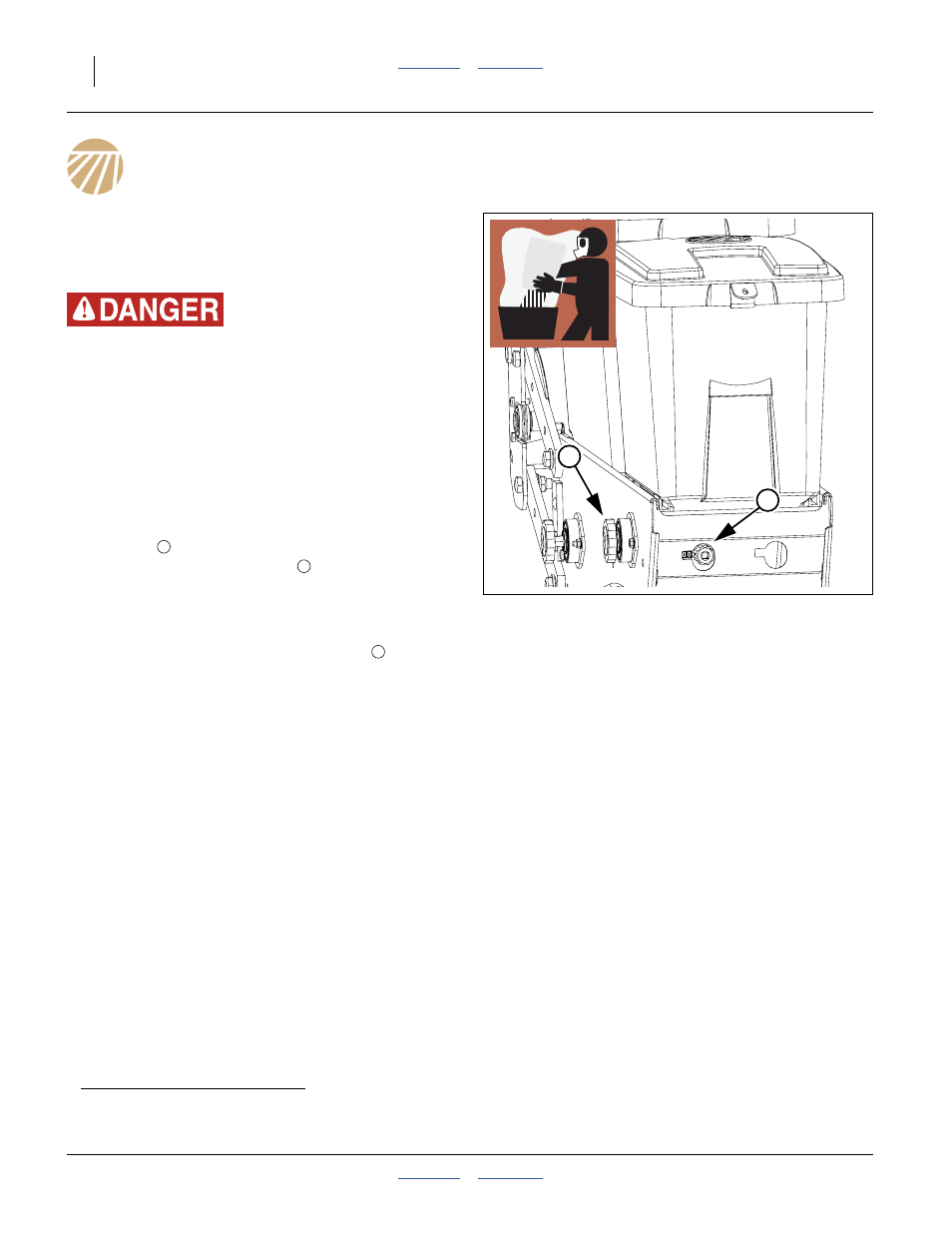

Refer to Figure 13 and Refer to Figure 14 on page 27

Treatment application rate is determined by a

combination of:

• meter dial

setting

(which controls the meter gate

• field speed

(application rate is inversely proportional to field

speed).

The system may be uncoupled at the clutch

treatment is being applied.

The treatment meter has an agitator powered by the

seed meter drive, but treatment application rate is

relatively

b

insensitive to agitator rpm.

There are four steps to obtaining the target treatment

weight in kg per hectare (or pounds per acre):

1.

Find your target rate, for your planned field speed, in

the charts beginning on page 30.

2.

Perform a Gate Calibration (see Operator manual) at

the start of each season, or if one or more rows is

metering at unexpected rates.

3.

Perform a Rate Calibration (page 28).

a. MSDS - Material Safety Data Sheet

b. Finer materials with low cohesion may flow when the planter is stopped. Set meters to “00” to prevent material loss.

3

1

Figure 13

Treatment Hopper and Meter

34452

2

3