Fertilizer range gears, Setting variable rate gearbox – Great Plains YP1630F-1670 Material Rate User Manual

Page 20

18

Great Plains Manufacturing, Inc.

YP1630F

401-832B

2012-12-04

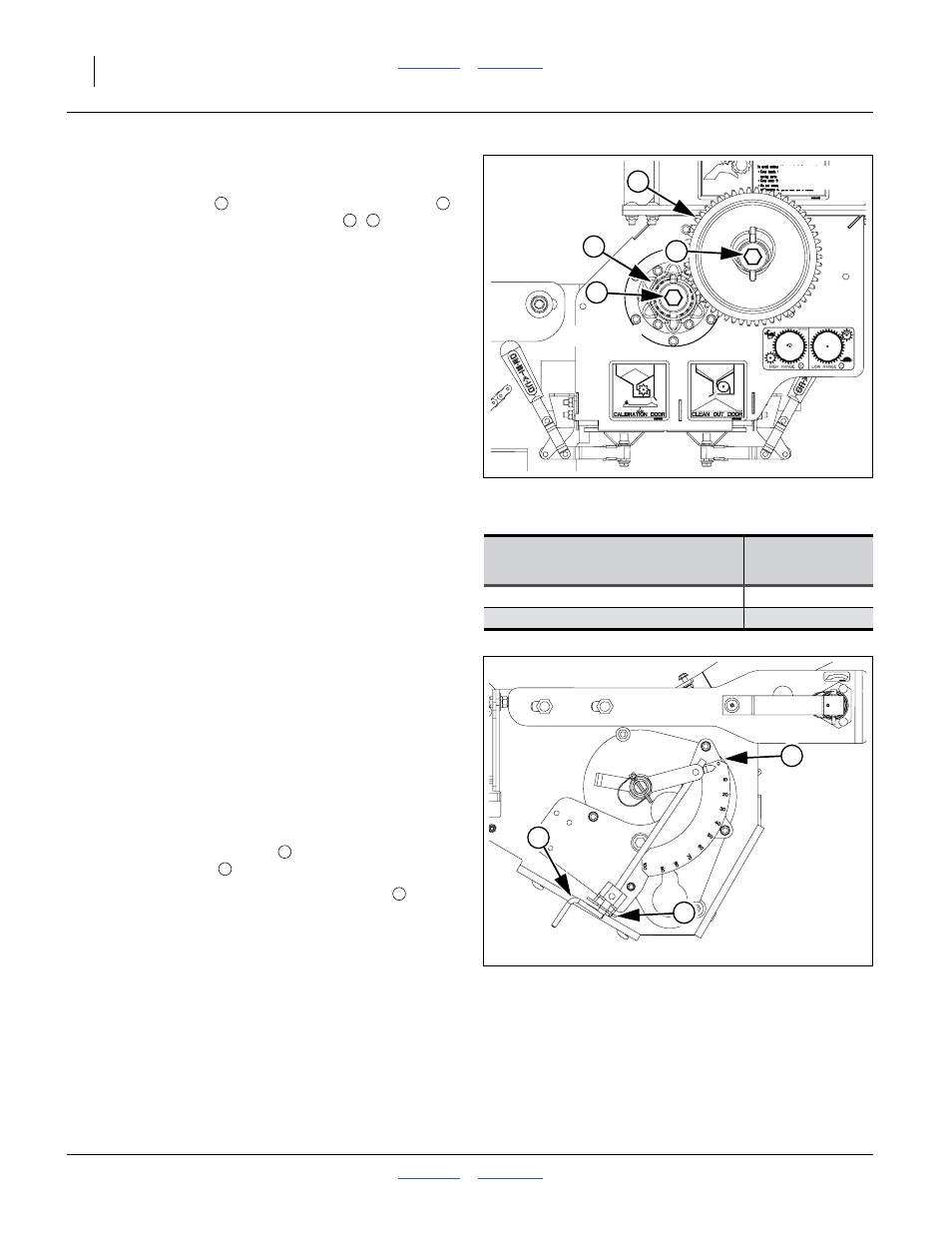

Fertilizer Range Gears

Refer to Figure 9

The meter flute shaft

is driven by the agitator shaft

through a pair of interchangeable gears

,

positioning of these gears creates two final drive ranges.

Each rate chart is based on a specific Final Drive Range.

The Ranges are:

• “High” range, which is used for higher fertilizer rates

• “Low” range, which is used for lower fertilizer rates

The two seed meter shafts are labelled “DRIVING” and

“DRIVEN”.

The “DRIVING” shaft is the upper/forward shaft.

The “DRIVEN” shaft is the lower/rear shaft.

Refer to the Seed Rate Chart (or Fertilizer Rate Chart),

the table below, and Figure 9 for setting the seed meter

final drive range.

1.

Remove the lynch pins from the gear ends of both

shafts.

2.

Remove and position the gears as shown in the table

above.

3.

Secure with lynch pins.

Setting Variable Rate Gearbox

The variable rate gearbox allows an arbitrarily variable

meter drive speed to attain a wide range of metering

rates. The ratio of gearbox input speed to output speed is

controlled by the position of a gearbox control arm. The

control arm has an indicator that points to a scale

marked in degrees. The Fertilizer Rate Charts show the

rate for each degree setting.

Refer to the rate charts and set the variable rate gearbox

control arm to its scale setting for the target rate.

To adjust the Variable Rate Gearbox:

Remove the hairpin cotter

securing the gearbox

adjustment crank

2.

Rotate crank until the control arm indicator

points

to the scale setting that matches the rate from the

chart, or as determined by calibration.

3.

Re-insert the hairpin cotter.

Note: The variable rate gearbox operates optimally

between 30 and 70. If your rate is listed on both the

Low Range and High Range charts, select the

chart where your rate results in a gearbox control

arm setting between 30 and 70. Settings below 20

degrees are not recommended. When the control

arm is set above 70 degrees, large movements of

the arm result in small changes in rate.

Figure 9

HIGH Final Drive Range

34500

FINAL DRIVE

RANGE

DRIVING

DRIVEN

LOW RANGE

17 Tooth Small

54 Tooth Large

HIGH RANGE

54 Tooth Large

17 Tooth Small

2

1

3

4

DRIVING

DRIVEN

3

4

Figure 10

Variable Rate Gearbox at 0

34501

5

6

7