Treatment rate calibration, Treatment rate calibration steps – Great Plains YP1630F-1670 Material Rate User Manual

Page 30

28

Great Plains Manufacturing, Inc.

YP1630F

401-832B

2012-12-04

Treatment Rate Calibration

Treatment Rate calibration is different from treatment

Gate calibration. Gate calibration is a seasonal activity,

and is described in the Operator manual.

Rate calibration requires:

• a precise scale for small weight values (the digital

scale provided for fertilizer calibration may be too

coarse);

• small plastic bags for sample collection at each row;

and,

• a representative field on which a 1000 m or 1000 foot

pass can be made, with openers in the ground, at your

intended planting/application speed.

Treatment Rate Calibration Steps

1.

Move the planter to the edge of the test field area.

2.

Mark a course of known length that is at least 300 m

in length. A course of exactly 1000 m or 1000 feet

simplifies calculations.

3.

Determine the rows to sample for treatment rate

calibration. A sample of three rows improves the

reliability of the sample data.

4.

Set the treatment meters for these rows to “00”.

Disengage the treatment drive clutches

at all other

rows. If the tested rows are all on the same wing,

lock up the ground drive for the other wing. See the

Operator manual for drive couple and ground drive

lock-up details.

6.

Disengage all seed meter clutches not already

disabled by lock-up. Disengage all treatment meter

clutches at rows not being tested (unless

disengaged by drive lock-up).

7.

Lock up the fertilizer ground drive.

8.

Lower the planter rows into the ground.

Wear protective equipment for this and all following

steps.

9.

At the rows identified in step 3, load a small amount

of treatment material, about twice the amount

expected to be metered over the course length. The

charts, starting on page 30, show the kg or ounces

expected for one row.

Mis-application Risk:

Speed and distance matter. Treatment flow (per minute) is

proportional to meter gate opening (dial setting), but is

relatively constant per minute, which makes it inversely

proportional to field speed. Further, material is flowing during

initial acceleration, at a higher net rate. Sample collection

must be performed at actual intended planting/application

speed, or the calibrated meter setting will not provide the

desired application rate. The sample must also be collected

over a sufficient distance to minimize errors due to the

elevated rate at start up.

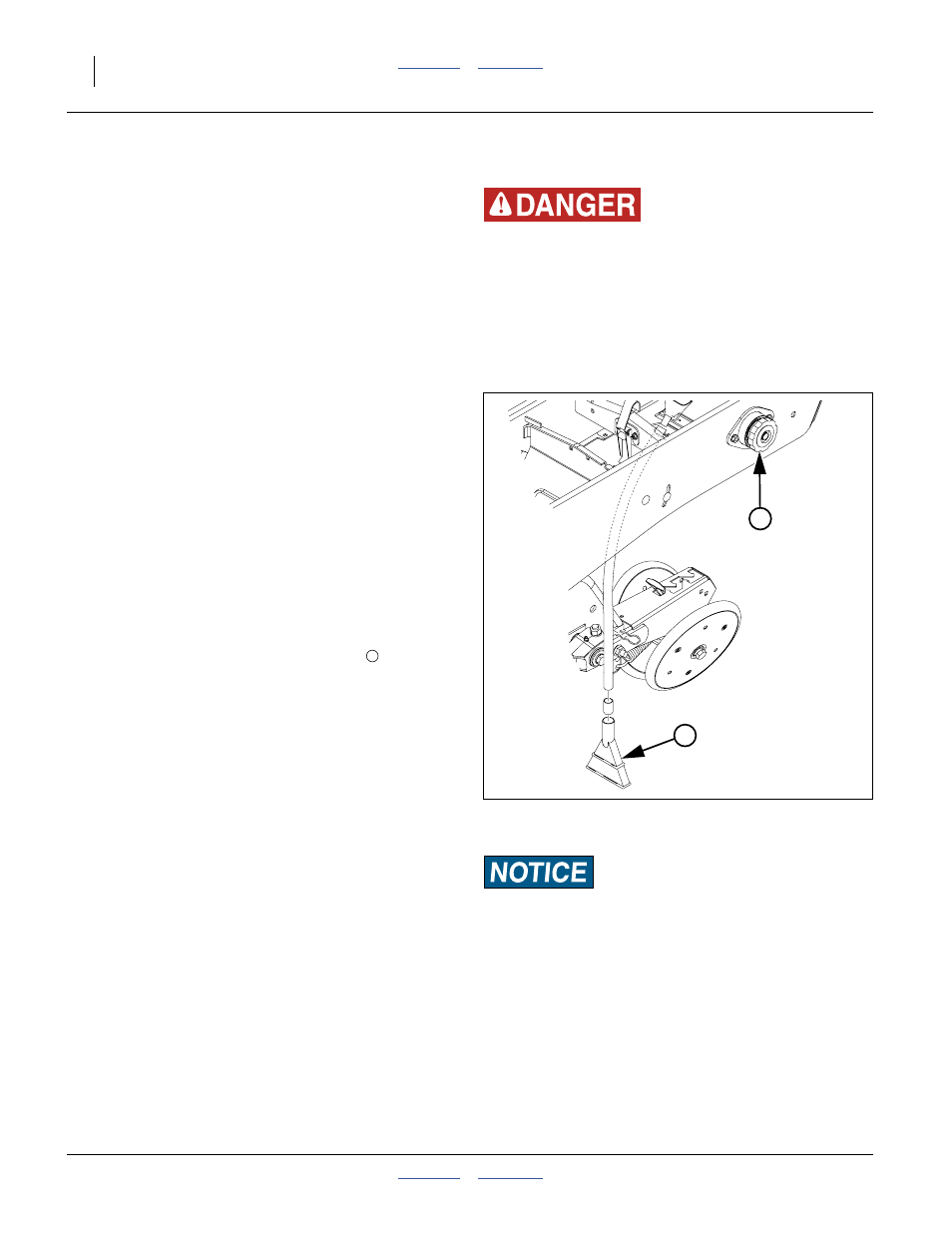

Figure 15

Treatment Drop Tube

34495

4

Agricultural Chemical Hazard:

Follow all chemical supplier precautions for handling

treatments. Wear protective equipment prescribed for the

current material, and for all previous materials used since

last thorough hopper clean-out. Read and follow material

label directions. Obtain and retain Material Safety Data Sheet

(MSDS) information for the present and recent materials.

Many treatments are extremely hazardous and can cause

disabling or fatal injury.