O-ring information, Assembly (cont.), Danger – Viking Pump TSM640: Lid-Ease Strainers User Manual

Page 3

SECTION TSM

640

ISSUE

F

PAGE 3 OF 4

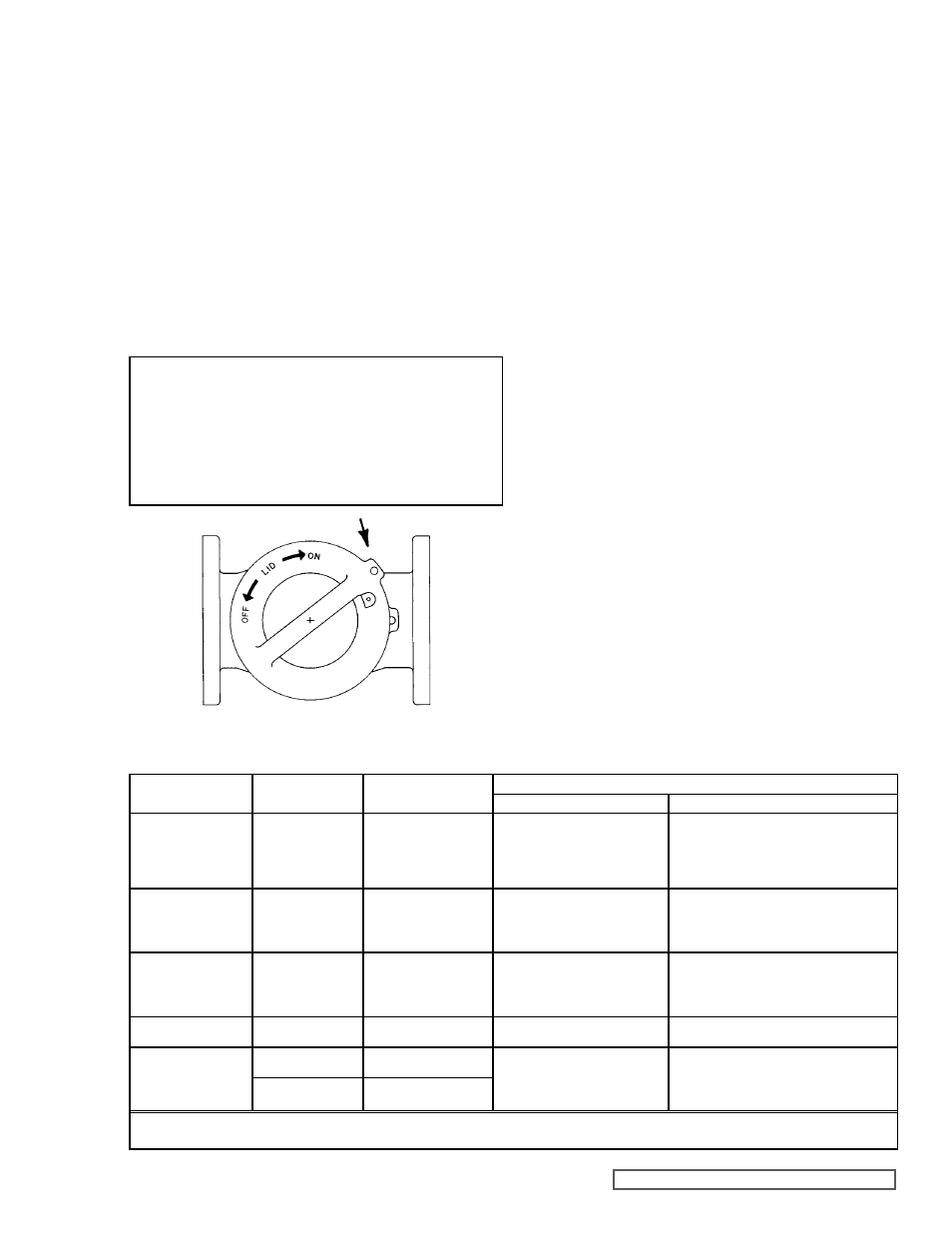

NOTE: When installing a new o-ring, it is recommended that

the o-ring be lubricated with grease before installing onto

the lid.

DANGER !

Before starting the system, be sure the lid

is turned to the proper position and the

thumbscrew is installed to prevent the lid

from turning

FIGURE 2

O-RING INFORMATION

Proper application and use of the o-ring elastomer will affect

the ease of lid removal and the life of the o-ring. Compatibility

of the elastomer with the fluid(s) at operating temperature

extremes, is essential and

Table B lists suitability for several

o-ring elastomers, along with Viking’s means of identification.

If an o-ring is incompatible with a fluid, excessive o-ring swell

or contraction might result and/or properties of the elastomer

may change, reducing the satisfactory performance life of

the o-ring. Included in Table B is a general list of fluids that

Parker’s O-Ring Manual does and does not recommend

for specific elastomers. Obviously if an o-ring should swell,

sealing will be enhanced between lid and body, but would

make the lid difficult to remove. Conversely, o-ring shrinkage

will reduce sealing and possibly cause a leak. Several good

sources are available covering o-ring compatibility. These

include o-ring manufacturers literature, Viking Pump’s Liquid

List, Viking’s Application Department, manufacturers of other

components in the system and previous experience.

Generally it is best to have an extra o-ring on hand when

removing the lid. Once the lid has been removed, if any

swelling has occurred, reinstalling the lid with the existing

o-ring will be difficult (if not impossible) and may require

another o-ring. Once o-ring dries out, it can sometimes be

used again.

PTFE (Derivative) Encapsulated o-rings generally do not

swell. Do not attempt to reuse this type of o-ring if it has been

removed. Immerse a new o-ring in boiling water for a few

minutes. Remove from the water and stretch out the o-ring so

it will fit onto the casing hub of the lid without forcing it over

a sharp edge. Run hot water over the o-ring until it shrinks

down tight into the groove of lid.

3. Rotate the lid clockwise until the two holes line up.

4. Reinsert the thumbscrew.

5. Reinstall the drain plug (if removed) or close the drain

valve (if installed).

6. Before starting up the system, make sure to open all

valves that were closed for servicing. After starting up

the system, check for any possible leaks. If there is any

leakage around the lid, return to Disassembly. Remove

the lid and refer to Trouble-Shooting, page 4, for possible

causes of leakage.

TYPE OF ELASTOMER

VIkING

IDENTIFICATION

TEMPERATURE LIMIT ①

LIMIT °F

LIqUIDS ②

RECOMMENDED

NOT RECOMMENDED

BUNA

NO DOT

-20 TO +225

Petroleum, oils and fluids

Silicone greases & oils

Ethylene glycol base

General purpose sealing

Halogenated hydrocarbon

Nitro hydrocarbon

Phosphate ester

Ketones

Ozone

Automotive break fluid

VITON

GREEN DOT

-15 TO +400

Petroleum oils

Di-Ester base lubricant

Silicone fluids & grease

Halogenated hydrocarbon

Selected phosphate ester acids

Ketones

Skydrol

Amines

Low molecular weight esters & ethers

Hot hydrofluoric or chlorosulfonic acids

ETHYLENE PROPYLENE

RUBBER

ORANGE DOT

-65 TO +300

Water

Dilute Acids

Dilute alkalies

Ketones

Alcohol

Petroleum Oil

Di-Ester base lubricant

SANITARY

YELLOW DOT

-20 TO +225

Same as Buna-N

PTFE (DERIVATIVE)

ENCAPSULATED

NO DOT ORANGE

CORE

(STANDARD)

-40 TO +300

Most solvents & chemicals

Consult factory if unsure about

compatibility

Molten alkali metals

Fluorine and strong

fluorinating agents

NO DOT

PURPLE CORE

(HIGH TEMP)

-40 TO +400

① Temperatures listed are for static seal applications only for the Lid-Ease Simplex strainer line.

② Source: Parker O-Ring Handbook (except for PTFE (Derivative) Encapsulated).

TABLE B

O-RING SELECTION

ASSEMBLY (Cont.)