Installation, Assembly, Disassembly – Viking Pump TSM640: Lid-Ease Strainers User Manual

Page 2: Danger

SECTION TSM

640

ISSUE

F

PAGE 2 OF 4

INSTALLATION

Strainers should be placed ahead of any equipment needing

protection. The mesh size used in the strainer body should be

only as small as required to protect the equipment. This will

minimize the pressure drop through the strainer. For pump

protection locate the strainer on suction side of the pump.

Proper sizing of the strainer and basket mesh can prevent

the pump from cavitating due to excessive pressure drop

across the strainer. There are several factors which influence

pressure drop such as viscosity of fluid, percentage and size

of particles or contaminants, and frequency of cleaning.

If the liquid contains undesirable ferrous particles, magnetic

inserts can be added to the baskets to help remove these

particles.

A second strainer (or filter) located on discharge side of pump

may be desirable to protect other equipment in the system

which requires a smaller mesh basket for finer straining of

the liquid. A basket with a smaller mesh opening (the higher

the mesh number, the smaller the opening in the mesh) can

be permitted on the discharge side because pressure drop is

less critical. Maximum differential pressures allowable across

strainers are listed in

Table A.

Locate the strainer in a position where the drain plug can

be easily removed (Replace the plug with a drain valve for

frequent maintenance). Provide adequate space above the

strainer for basket removal as listed in table A. The Lid-Ease

strainer has cast arrows on the body to indicate the direction

fluid must flow. These strainers are not designed for any type

of backwash operation.

NOTE: Mounting the strainer with ports in a vertical position

is

NOT recommended because of increased difficulty during

servicing.

For the larger strainers, additional external support of the

strainer may be required to reduce pipe strain in the system.

This can be accomplished either by supporting the flanges or

providing a base for the bottom of the strainer. Lid removal for

maintenance will be much easier if the top of the strainer is

not over 3 feet off the ground. In the event that the strainer is

not at highest point in the system, valves are recommended

on both sides of strainer to prevent the strainer from filling up

while cleaning the basket.

As the basket becomes clogged with foreign matter,

differential pressure will rise.

Table A shows maximum

pressure differential allowable across the basket. If this

pressure is exceeded, damage to the basket may occur. A

good way to indicate when basket must be cleaned is to: 1)

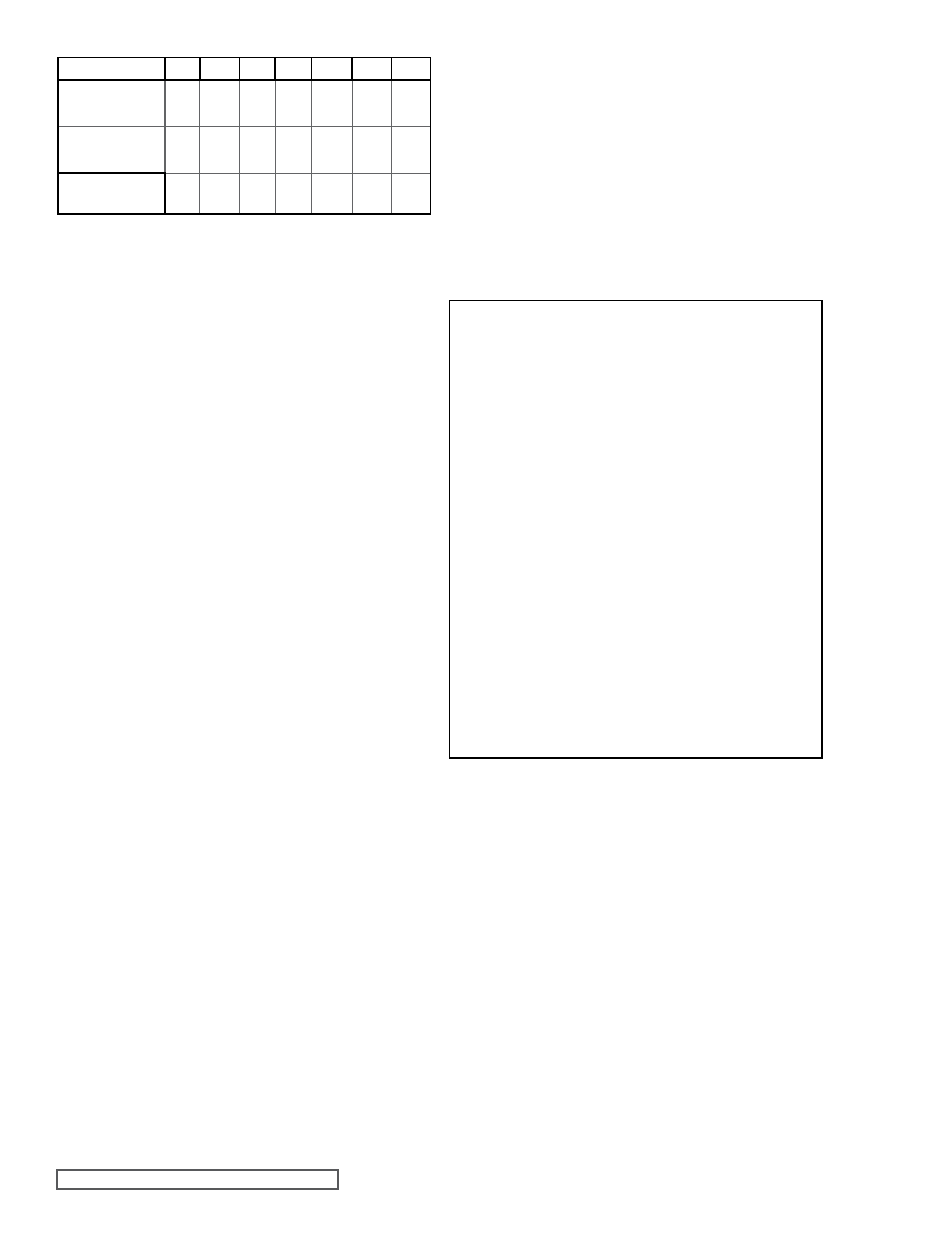

Strainer Size

1”

1 1/2”

2”

3”

4”

6”

8”

Basket Clearance

(Required from

port centerline)

6.0

6.5

7.5

9.5

11.75 16.5

24.5

Maximum Basket

Differential

Pressure (PSID)

150

150

150

125

125

75

50

Maximum System

Pressure (PSIG)

200

200

200

①

125

①

125

①

125

①

125

①

175 PSI on liquid temperature below 150 °F

NOTE: Before removing the lid to clean the basket make

sure that you have a spare o-ring in the event that the fluid

being strained has caused the o-ring to swell.

1. Remove the thumbscrew from top of lid.

2. Rotate the weatherseal lid counter clockwise until the pin

hits and stops. (The lid features an internal pin, which

locates the on and off positions.)

3. Raise up the lid.

4. Remove the basket and clean. Do not strike the basket

to clean it out; this could deform the basket side or lip

and decrease the strainers effectiveness. Avoid using a

sharp object such as a screwdriver, which could puncture

the mesh. To clean the basket, use a small brush or

compressed air.

ASSEMBLY

1. Place basket into strainer body.

2. Reinstall the lid with the tab of the lid just to the left of the

boss with the threaded hole on the body (See fig. 2).

NOTE: Do not attempt to install the lid if the strainer has

filled up; drain before installing the lid. Press down on

the lid firmly and evenly until it pops into place.

DANGER !

Before opening any Viking product (Strainer,

pumping chamber, reservoir, relief valve

adjusting screw cap etc.) be sure:

1. That any pressure in the strainer or pumping

chamber has been completely vented through

suction or discharge lines or other appropriate

openings or connections.

2.

That the driving means (motor, turbine,

engine, etc.) has been “Locked Out” or made

non-operational so that it cannot be started

while maintenance is being preformed.

3. That you know what liquid the strainer has

been handling and the necessary precautions

to safely handle the liquid. Obtain a Material

Safety Data Sheet (MSDS) for the liquid to be

sure these precautions are understood.

Failure to follow above listed precautionary

measures may result in serious injury or

death.

Install a pressure differential gauge or 2) install a pressure

gauge on each side of the strainer.

NOTE: Strainers located on the discharge side of the pump

must have a safety relief valve between the pump and the

strainer set no higher than the strainer’s maximum system

pressure (see Table A).

TABLE A

DISASSEMBLY