Viking Pump TSM640: Lid-Ease Strainers User Manual

Viking Pump Pumps

SECTION TSM

PAGE

ISSUE

VIKING PUMP, INC.

•

A Unit of IDEX Corporation

•

Cedar Falls, IA 50613 USA

VIKING PUMP, INC.

•

A Unit of IDEX Corporation

•

Cedar Falls, IA 50613 USA

TECHNICAL SERVICE MANUAL

INTRODUCTION

640

1

E

This bulletin deals exclusively with Viking Lid-Ease®

Basket-Type Strainers. When ordering parts be sure to give

complete part name, serial number and model number (cast

on body below serialized nameplate). The basket mesh size

is stamped on the basket handle and the o-ring construction

can be identified with a Viking color code (listed under O-Ring

Information).

Use of basket strainers can avoid costly failures and increase

the life of the equipment. Proper use of strainer can minimize

down time. A definition for strainers is “a coarse filter”.

Strainers are typically intended to trap larger foreign objects

DANGER !

Before opening any Viking product (Strainer,

pumping chamber, reservoir, relief valve

adjusting screw cap etc.) be sure:

1. That any pressure in the strainer or pumping

chamber has been completely vented

through suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor, turbine,

engine, etc.) has been “Locked Out” or

made non-operational so that it cannot

be started while maintenance is being

preformed.

3. That you know what liquid the strainer

has been handling and the necessary

precautions to safely handle the liquid.

Obtain a Material Safety Data Sheet (MSDS)

for the liquid to be sure these precautions

are understood.

Failure to follow above listed precautionary

measures may result in serious injury or

death.

Viking does not recommend using Lid-Ease Strainers for the

following applications:

1. Fluids having vapor pressure higher than one atmosphere,

either at room temperature or operating temperature.

2. Straining of particles finer than 70 microns (50Х250 Mesh

available through 4”).

3. Temperatures below -40 ºF or above +400 ºF.

4. High system pressure applications (See Table A, Page 2).

5. High basket differential pressure (See Table A).

6. Aluminium strainer handling 1,1,1-trichloroethane,

methylene chloride or halogenated hydrocarbon solvents.

Determine and exercise necessary precautions before

removing the lid, involving fluids which are:

-

POISONOUS OR TOXIC

-

FLAMMABLE

-

HARMFUL TO FACE OR HANDS

-

HOT (Liquids containing boiling water (+212º F at sea

level) can produce steam; extra care to properly vent

strainer must be exercised).

-

ENTRAINED WITH AIR (Trapped, pressurized air under

lid can lift the lid suddenly and violently if the lid is rotated.

Be the sure system is completely vented)

DO NOT ATTEMPT TO VENT THE SYSTEM BY TURNING

THE LID.

SPECIAL INFORMATION

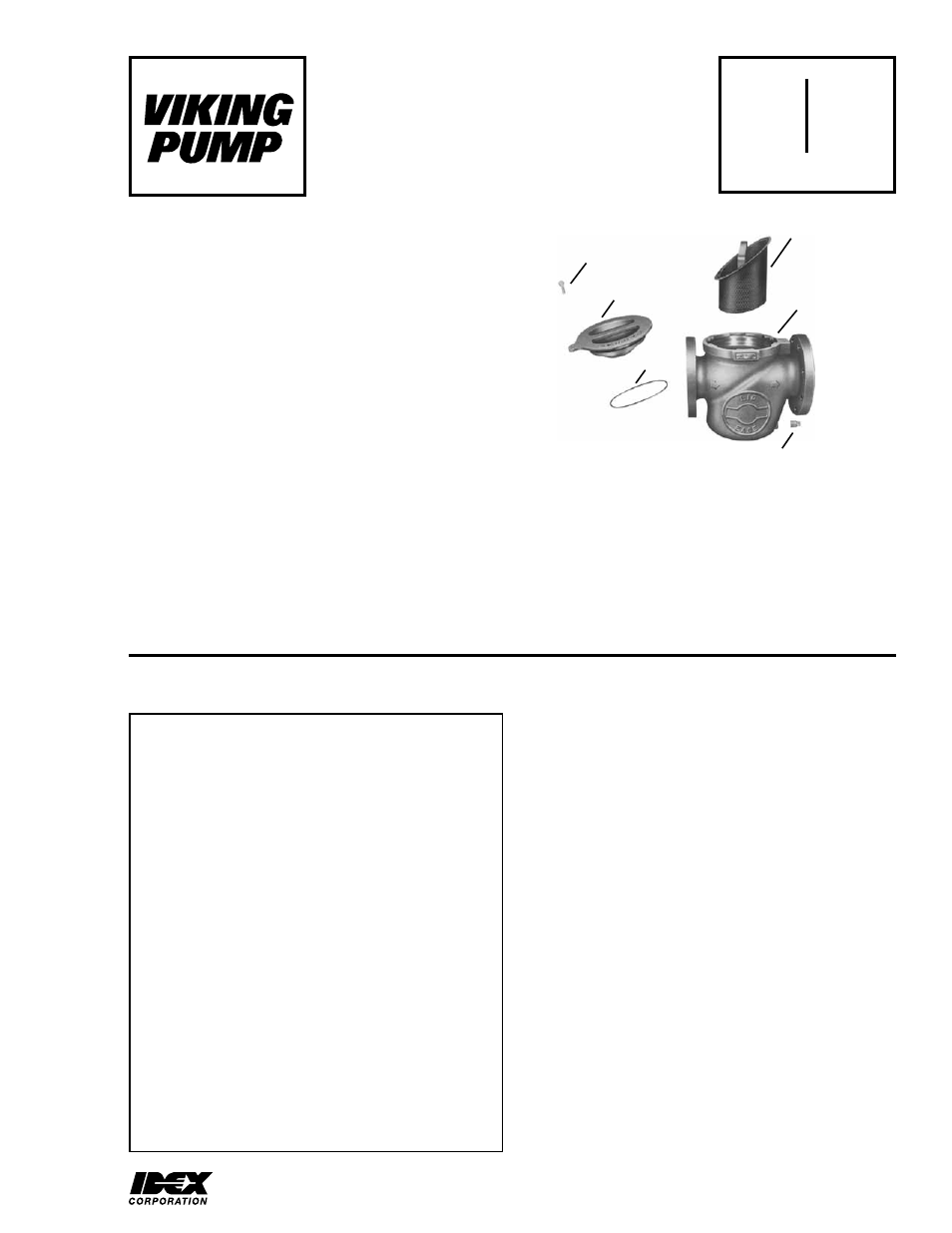

FIGURE 1

CONTENTS

Introduction.....................................................................1

Contents.........................................................................1

Special Information.........................................................1

Installation.......................................................................2

Disassembly....................................................................2

Assembly.........................................................................2

Assembly (Cont.).........................................................3

O-ring Information...........................................................3

Warranty.........................................................................4

STRAINER

BASKET

STRAINER

BODY

PLUG

O-RING

LID

THUMBSCREW

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

such as rags, weld beads or bolts. Filters are intended to

capture very small particles.

Lid sealing is accomplished with one o-ring, therefore

proper application of o-ring is essential. The o-ring must be

acceptable for the temperature limits of the system as well

as compatible with the fluid being strained. Misapplication

may result in o-ring swell, (making lid removal difficult) or

premature o-ring failure, causing strainer leakage.

LID-EASE® SIMPLEx

IN-LINE BASkET-TYPE STRAINERS