Disassembly / assembly of bracket bearings, Disassembly, Assembly – Viking Pump TSM635.1: H-HL Universal Mag Drive User Manual

Page 6

SECTION TSM

635.1

ISSUE

E

PAGE 6 OF 12

9. Visually inspect the outer magnets from the end of the

bracket. If removal is necessary, separate the bracket

from the motor. Remove the locknut (1), lockwasher (2)

and outer bearing spacer collar (4) from the shaft. Slide

the outer magnet assembly out of the bracket. Inspect

the magnet assembly for damage or wear; replace

if needed. If further disassembly of the bracket is

required, see

“Disassembly / Assembly of Bracket

Bearings”.

10. Remove the socket head capscrews (54) from the

canister (59). If the canister was not drained in Step

1, it will contain liquid. Use care when removing the

canister from the pump by pulling it straight off. Inspect

the canister bushing (64) for wear. If the canister

bushing needs to be replaced, see

“Installation of

Bushings” on page 7.

11. Do not remove the O-ring from the plate adaptor

(67) / canister unless it is bad, especially if it is PTFE

(derivative) encapsulated. If a new O-ring is required,

See

“Pump Assembly” on page 8.

12. Insert a brass bar into the rotor (36) through a port

between two rotor teeth and remove the split locknut

(66), see

Figure 8. Slide the inner magnet assembly

off of the shaft. Make sure the outer thrust washer (60)

does not come off with the inner magnet assembly. If

the thrust washer hits the shaft key (62) it may crack

or break. Do not forget this is a very strong magnet.

Inspect the magnet assembly for damage or wear;

replace if needed. If further disassembly is required,

proceed to the next step.

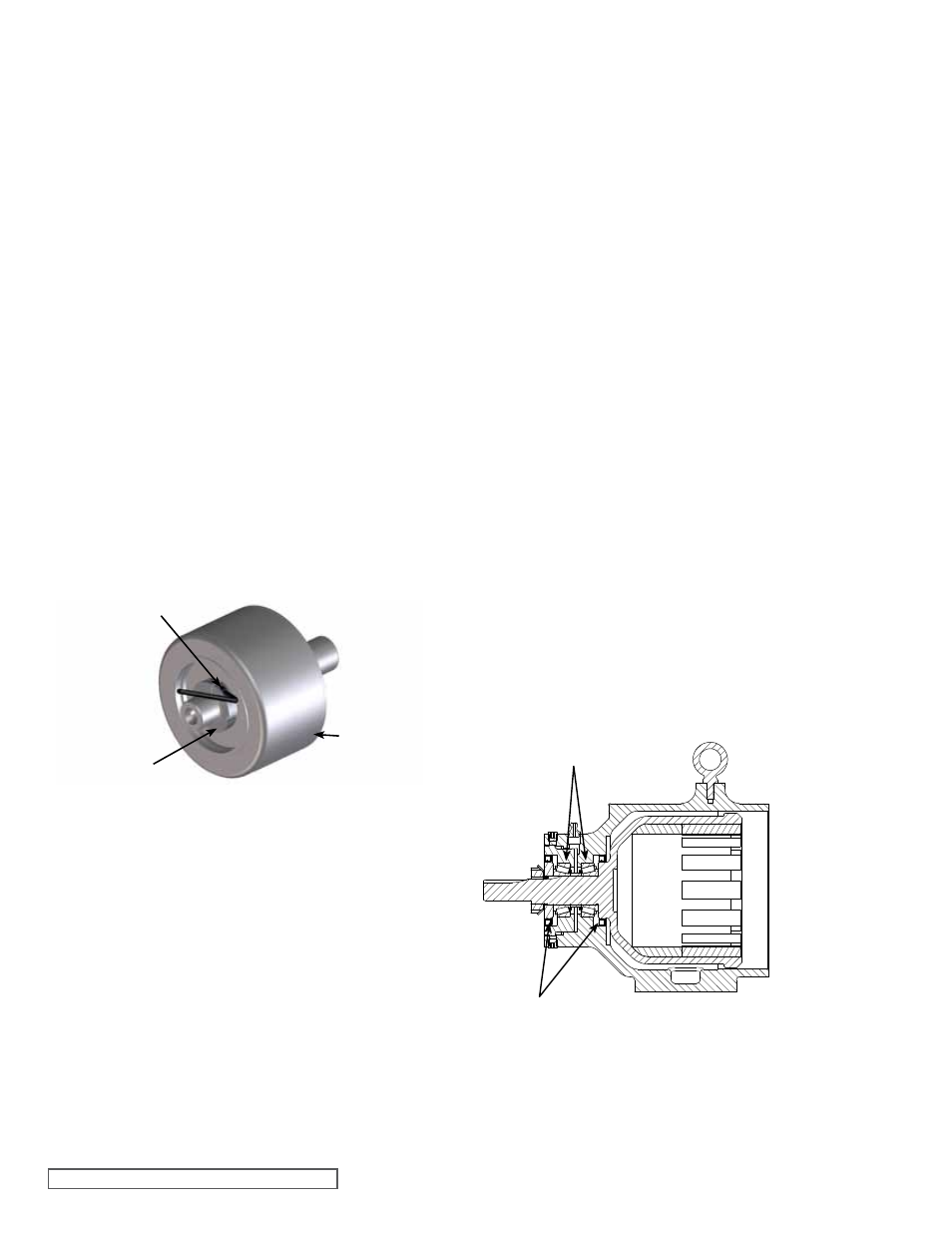

FIGURE 8

INNER MAGNET AND LoCKNUT ASSEMBLY

DISASSEMBLY / ASSEMBLY oF

BRACKET BEARINGS

DISASSEMBLY

The bracket bearing assembly features two tapered roller

bearings, two lipseals, and one spacer. If further disassembly

of this unit is required, proceed as follows:

1. Loosen the setscrews holding the end cap (3) in the

bracket. Screw the end cap out of the bracket.

2. Inspect the bearings (6) for wear; replace as needed.

3. Inspect the lipseals (5) for wear; replace as needed. The

lipseals will need to be replaced if removed.

4. If the bearings are worn it is recommended to replace

the entire bearing. Remove the inner bearing spacer

collar (8). Press the inner bearing cup (6) out of the

bracket and the outer bearing cup out of the end cap.

The bearings will need to be replaced if the cups are

removed.

ASSEMBLY

1. If the bearing cups were removed, press the cup of the

outer bearing into the end cap. Press the cup of the inner

bearing into the bracket.

2. Press the inner lipseal into the bracket and the outer

lipseal into the end cap and then lubricate the lipseals,

see

Figure 9 for lipseal and bearing orientation.

FIGURE 9

BRACKET BEARING AND LIPSEAL oRIENTATIoN

SETSCREW

LoCKNUT

INNER

MAGNET

ASSEMBLY

TAPERED RoLLER BEARINGS

LIPSEALS

13. Remove the shaft key from the rotor shaft. Remove

the outer thrust washer. The rotor and shaft (36) may

now be removed by tapping on the end of the shaft

with a soft face hammer (If a soft face hammer is not

available a regular hammer may be used with a piece of

hardwood). Remove the inner thrust washer from behind

the rotor. Check the thrust washers for cracks or wear;

replace if necessary.

14. Inspect the adaptor plate bushing. If the bushing needs

to be replaced, see

“Installation of Bushings”, page

7. Remove the socket head capscrews (13) from the

adaptor plate. Slide the adaptor plate out of the casing.

15. Do not remove the O-ring from the plate adaptor / casing

unless it is bad, especially if it is PTFE (derivative)

encapsulated. If a new O-ring is required, See

“Pump

Assembly” on page 7.

16. Inspect the casing for wear, particularly in the area

between the ports. Clean all other parts thoroughly and

examine for wear or damage.

When making major repairs, such as replacing a rotor and

shaft, it is advisable to also install a new head and idler

pin, idler and bushing, and adaptor plate bushing. See

“Installation of Bushings” on page 7.

3. Screw the end cap into the bracket (clockwise) until it

contacts. Do not over-tighten the end cap.

4. Inspect the outer magnet to make sure it has not picked

up any foreign particles, which could damage the pump.