Unit installation, Harmful situation, Nord gear corporation – Viking Pump NORD TSM For NORDBLOC.1 Reducers User Manual

Page 6: Nord gear limited, Retain for future use

DRIVESYSTEMS

UNIT INSTALLATION

RETAIN FOR FUTURE USE

U10060 - 1 of 2

1. Installation site

Drives must be properly installed if they are to produce the

rated torque. Improper installation may lead to oil leaks, re-

duced life, or even catastrophic failure. NORD gear drives

and motors are intended to be installed at a suitable mount-

ing site under the following conditions:

t 6OJNQFEFEBJSnPXUPBOEBSPVOEUIFVOJUT

t "DDFTTJCJMJUZUPPJMESBJO

MFWFMBOECSFBUIFSQMVHT

t 0OCSBLFNPUPST

BMMPXBEFRVBUFTQBDFGPSSFNPWJOHUIF

fan guard and replacing and adjusting the brake.

t .PVOUJOH TVSGBDFT NVTU CF nBU

UPSTJPOBMMZ SJHJE

BOE

dampened against vibration.

t 6OMFTTTQFDJBMNFBTVSFTBSFUBLFO

UIFJNNFEJBUFWJDJOJUZ

around the gear drive or motor should not be exposed

to any aggressive or corrosive substances, contaminated air,

ozone, gases, solvents, acids, alkalis, salts, radioactivity, etc.

2. Mounting position

Reducer mounting position charts illustrate the standard

mounting positions for horizontal and vertical mounting.

"MMHFBSVOJUTBSFBTTFNCMFEXJUIUIFPJMmMMMFWFM

PJMESBJO

and vent plugs installed in their proper locations, according

to the customer-specified mounting position. For mounting

orientations other than shown consult NORD Gear.

STOP

HARMFUL SITUATION

STOP

The gear reducer may not receive proper lubrication if

the unit is not mounted in the position for which it is

designed. Observe the mounting position designated

PO UIF SFEVDFS OBNFQMBUF

PS TQFDJmFE JO UIF PSEFS

acknowledgement. Consult NORD prior to changing

NPVOUJOHQPTJUJPOJOUIFmFME8IJMFJUJTPGUFOQPTTJCMF

UP TJNQMZ SFMPDBUF UIF PJM mMMMFWFM BOE WFOU MPDBUJPOT

BOEBEKVTUUIFPJMmMMBNPVOU

JOTPNFDBTFT

EJGGFSFOU

mounting positions may lend themselves to different

internal construction features.

3. Reducer mounting

t 5IFTVQQPSUGPVOEBUJPONVTUCFTUSBJHIU *FWFMBOEnBU

8IFUIFS UIF HFBS VOJU JT GPPUNPVOUFE PS nBOHF

mounted, NORD recommends that the straightness and

nBUOFTT PG UIF DVTUPNFSTVQQMJFE TVQQPSU GPVOEBUJPO

follow Table 1.

t 5IF HFBS VOJU NVTU CF QSPQFSMZ BMJHOFE XJUI UIF ESJWFO

shaft of the machine in order to prevent additional

stress or load forces from being imposed upon the gear

unit.

t 5P GBDJMJUBUF PJM ESBJOBHF JU NBZ CF EFTJSBCMF UP FMFWBUF

the gear box foundation above the surrounding

support structure.

t "MM CPMUJOH TVSGBDFT NVTU CF DMFBO BOE GSFF GSPN

contamination and corrosion.

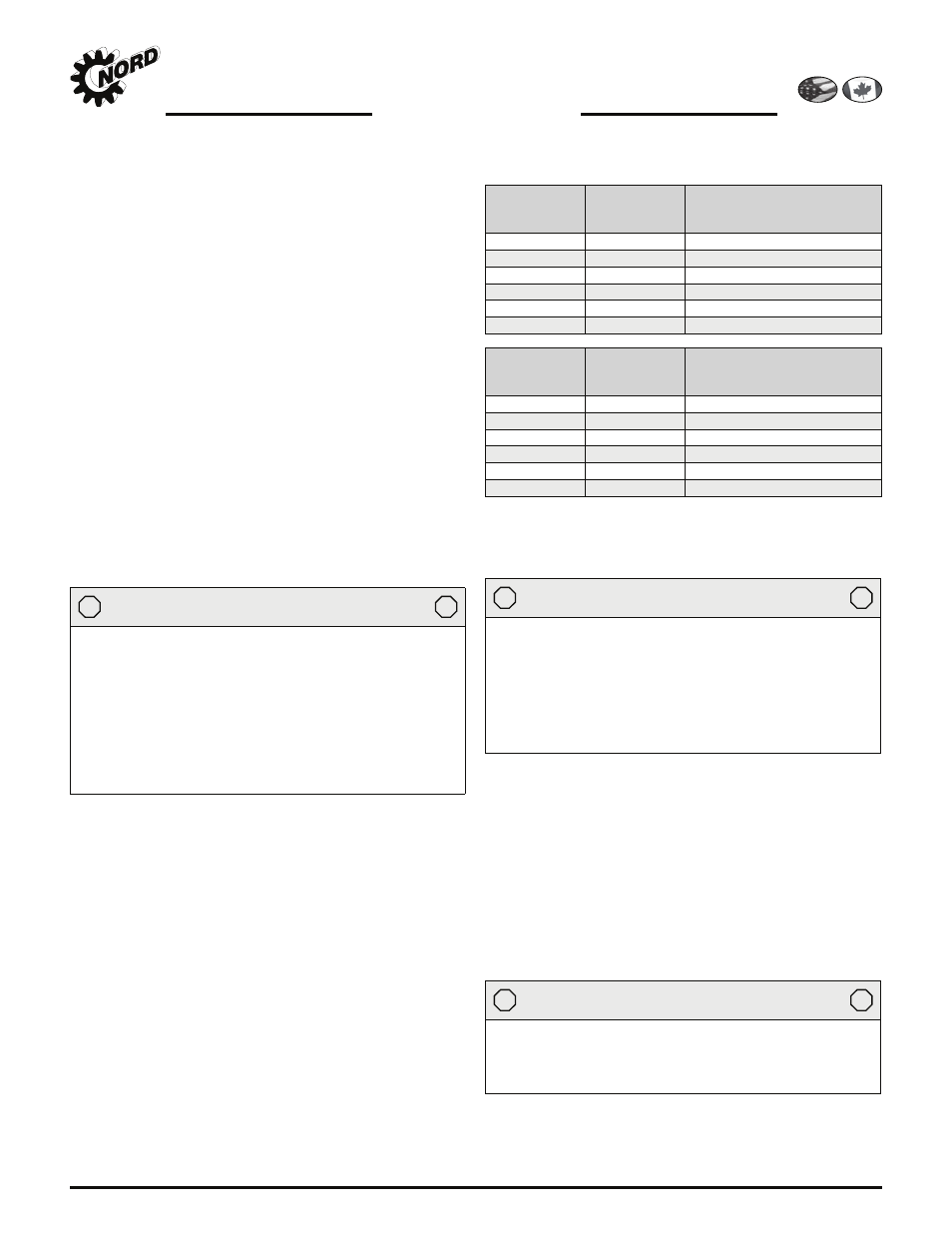

Table 1: Recommended Straightness and Flatness of

Customer-Supplied Support Foundation

Above

(in)

To &

Including

(in)

General Tolerance on

Straigtness & Flatness

ISO 2768-2, Tolerance Class K

0.00

0.39

+/- 0.002 in

0.39

1.18

+/- 0.004 in

1.18

3.9

+/- 0.008 in

3.9

11.8

+/- 0.016 in

11.8

39

+/- 0.024 in

39

118

+/- 0.031 in

Above

(mm)

To &

Including

(mm)

General Tolerance on

Straigtness & Flatness

ISO 2768-2, Tolerance Class K

0

10

+/- 0.05 mm

10

30

+/- 0.1 mm

30

100

+/- 0.2 mm

100

300

+/- 0.4 mm

300

1000

+/- 0.6 mm

1000

3000

+/- 0.8 mm

Straightness: Based upon the length of the corresponding line.

Flatness: Based upon the longer lateral surface or the

diameter of the circular surface.

STOP

HARMFUL SITUATION

STOP

The responsibility for the design and construction of the

support foundation is with the user. The foundation

must be adequate to withstand normal operating loads

and possible overloads while maintaining alignment to

attached system components under such loads. Motors

and drive components mounted on prefabricated base

plates can become misaligned during shipment. Always

check alignment after installation

.

4. Steel foundation

"O FOHJOFFSFE TUSVDUVSBM TUFFM GPVOEBUJPO TIPVME CF

designed to provide adequate rigidity and prevent loads

from distorting the housing or causing misalignment of inter-

OBMHFBSTBOETIBGUT8IFOGPPUNPVOUJOHUIFHFBSSFEVDFS

a base plate or sole plate with suitable thickness (generally

equal or greater than the thickness of the drive feet) should

be securely bolted to steel supports and extend under the

FOUJSFHFBSESJWFBTTFNCMZ8IFOnBOHFNPVOUJOHUIFHFBS

unit, the bulk head plate must be engineered to minimize

buckling distortions and support the cantilevered weight of

the gear unit or gear motor.

STOP

HARMFUL SITUATION

STOP

Do not weld on the gear unit or use the gear unit as an

earth or ground connection for any welding procedure

as this may cause permanent damage to the bearings

and gears.

www.nord.com/docs

06.09.09

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

NORD Gear Limited

Toll Free in Canada: 800.668.4378