Installation locating the pump, Equipment, piping and hose, Electrical connections – Viking Pump TSM442: GG-AL 4195-G LP-Gas User Manual

Page 9

SECTION TSM 442

ISSUE

C

PAGE 9 OF 10

INSTaLLaTION

LOCaTINg THE PUMP

The pump should be mounted on a level surface A flat

concrete slab serves very well as a foundation Make sure

that there is a 12” or more vertical distance between the

bottom of the tank and the pump inlet port centerline The

greater the vertical distance between the bottom of the tank

and the pump inlet, the better the pump will perform and the

longer it will last

EQUIPMENT, PIPINg aND HOSE

All equipment, plus the piping, fittings, hose, etc must

be approved for use with LP-Gas The equipment and

installation must meet local standards as well as those of the

National Fire Protection Association (NFPA) Standard No

58 All threaded connections should be coated with a thread-

sealing compound approved for LP-Gas service

ELECTRICaL CONNECTIONS

All electrical hookups should be made by a qualified

electrician and must meet all applicable local and national

standards for installations handling LP-Gas

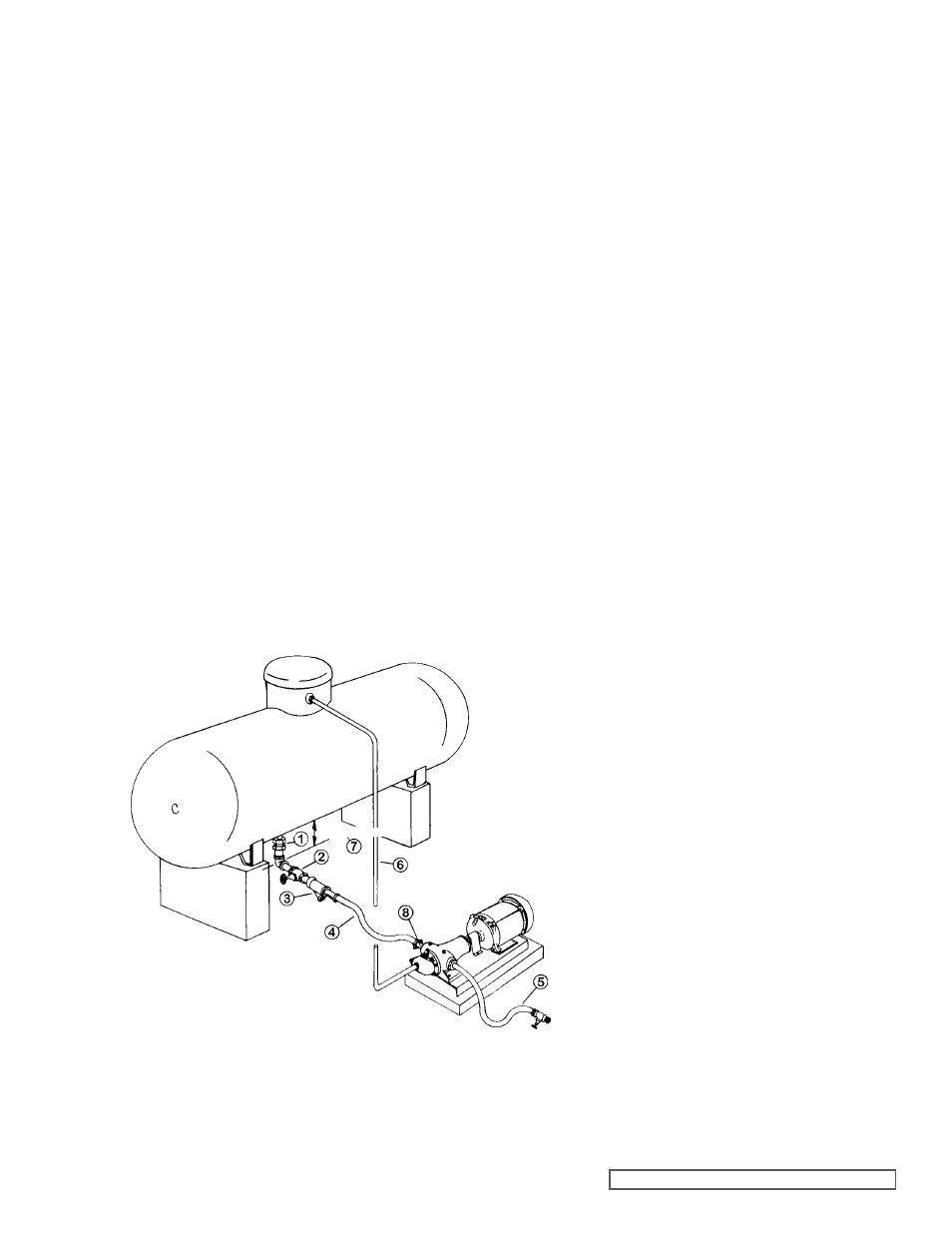

fIgURE 10

TYPICaL INSTaLLaTION Of VIkINg gg 4195D-g

LP-gaS PUMP UNIT SHOWINg RECOMMENDED

EQUIPMENT aND LOCaTION.

1. Excess Flow Valve

2. Shut Off Valve – Full opening type

3. Strainer, 40 mesh; optional

4. Hose, 1”; Maximum length 3 feet

5. Filler Hose, 75” Minimum with shut off valve and

filler connection; 15ft Maximum

6. Return Line, 0 50” Minimum, from by-pass Valve

7. Distance between bottom of tank and pump port

centerline should be at least 12 inches (one foot)

More vertical distance will help pump operate

better and last longer

8. Hydrostatic Relief should be installed in pump

inlet port or in inlet piping

1- 25” Fittings

and pipe

connection

}

12” Minimum