Thrust bearing adjustments, Valve instructions assembly – Viking Pump TSM442: GG-AL 4195-G LP-Gas User Manual

Page 6

SECTION TSM 442

ISSUE

C

PAGE 6 OF 10

7. Pack the lubrication chamber between the casing ball

bearing and the double row ball bearing in the bearing

housing approximately half full with

lithium base ball

bearing grease

8. Pack the double row ball bearing with lithium base ball

bearing grease and press into the bearing housing

Install the snap ring to hold the bearing in place

NOTE: On AS, AK and AL pumps, install the lipseal in

the bearing housing end cap Put the bearing spacer

sleeve in the lipseal and install this in the bearing

housing and tighten securely

9. Start the bearing housing into the casing Turn by

hand until tight This forces the rotor against the head

Replace and tighten the locknut on the shaft Insert a

piece of brass or hardwood through the port opening

between the rotor teeth to keep the shaft from turning

10. Adjust the pump end clearance as follows:

THRUST bEaRINg aDJUSTMENTS

Loosen the two setscrews in the bearing housing and

turn counterclockwise 0 25” measured on the outside of

the bearing housing of GG, HJ and HL size pumps This

represents approximately 002” end clearance On

the AS, AK and AL size pumps, turn the thrust bearing

assembly counterclockwise two notches which represents

approximately 003” end clearance

NOTE: Be sure the shaft can be rotated freely If not, turn

the bearing housing counterclockwise until the shaft can

be turned Be sure set screws are tightened securely after

adjustment is made High viscosity liquids require additional

end clearance The amount of end clearance depends on

the viscosity of the liquid being pumped

VaLVE INSTRUCTIONS

aSSEMbLY

1. Installing New Seal: The seal is simple to install and

good performance will result if care is taken in its

installation

NOTE: Never touch the sealing faces with anything except

the fingers or a clean cloth Clean the rotor hub, shaft and

seal seat housing in the casing, making sure they are clean

and free from dirt and grit

Coat the outside diameter of the seal seat and the inside

diameter of the seal seat and the inside diameter of the seal

housing bore with light oil With thumb and forefinger, push

the seal seat into place in the casing

Place the tapered sleeve (furnished with replacement seals)

on the shaft as far as it will go Thin end must be toward end

of shaft

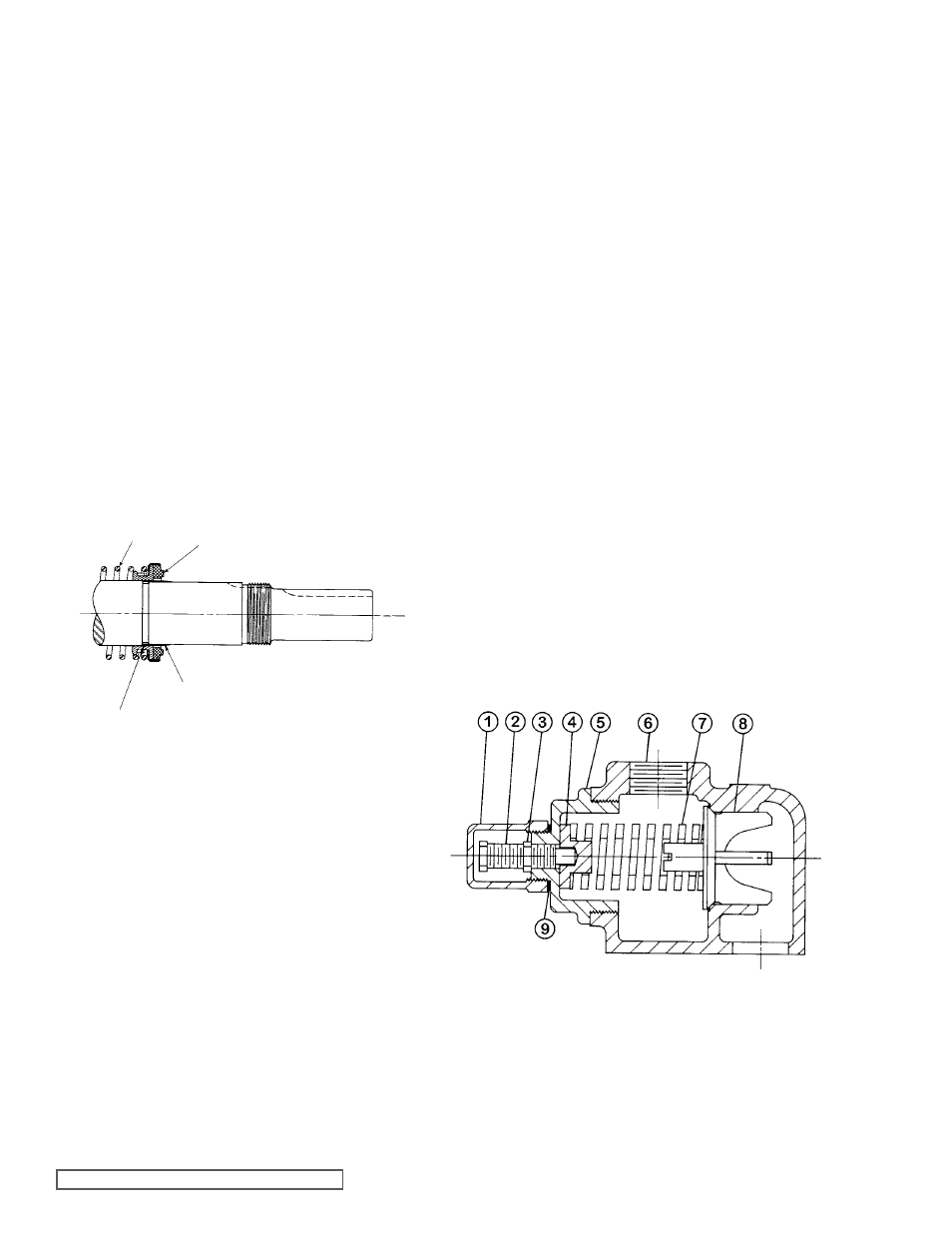

See figure 5. Coat the inside of the rotary member

and the outside of the tapered sleeve with light oil Be sure

the shaft is free of nicks and burrs Place the spring and

rotary member on the shaft, spring first, over the sleeve and

against the hub of the rotor Remove the tapered sleeve

2. Flush the sealing faces of both the rotary member and

seal seat with light oil and install rotor and shaft Push

the rotor and shaft into the casing slowly until the ends

of the rotor teeth are just beyond the face of the casing

3. Place the idler on the idler pin and the O-ring head

gasket on the head Place the head assembly on the

pump and tighten the capscrews evenly and securely

The seal is now automatically compressed to its proper

working length

4. Pack the single row ball bearing with grease and install

in the casing Install the snap ring in GG, HJ and HL

pumps

NOTE: The AS, AK and AL pumps do not have a

snap ring, but the bearing retainer washer must be

assembled over the end of the shaft before the bearing

is assembled

5. Place the bearing spacer over the shaft and against the

single row ball bearing in the casing (AS, AK, and AL

size pumps

6. Install the snap ring in the groove in the shaft on the HJ

or HL size pumps

fIgURE 5

SPRINg

MECHaNICaL SEaL

(ROTaRY MEMbER)

COaT WITH LIgHT OIL

bEfORE aSSEMbLY

TaPERED SLEEVE

fIgURE 6

“gg” , “HJ” aND “HL” SIZE