Viking Pump TSM442: GG-AL 4195-G LP-Gas User Manual

Page 8

SECTION TSM 442

ISSUE

C

PAGE 8 OF 10

SUPPLEMENTaRY SECTION

INTRODUCTION

Your Viking Model GG 4195G pump is a high quality pump,

which will give you years of service if properly installed

Correct installation, particularly with regard to the vertical

distance between the bottom of the tank and the pump inlet

port, and the size of suction fittings and the size and length

and the size and length of the suction hose is very important

on any LP-Gas pump Improper installation will result in

reduced service life of your pump

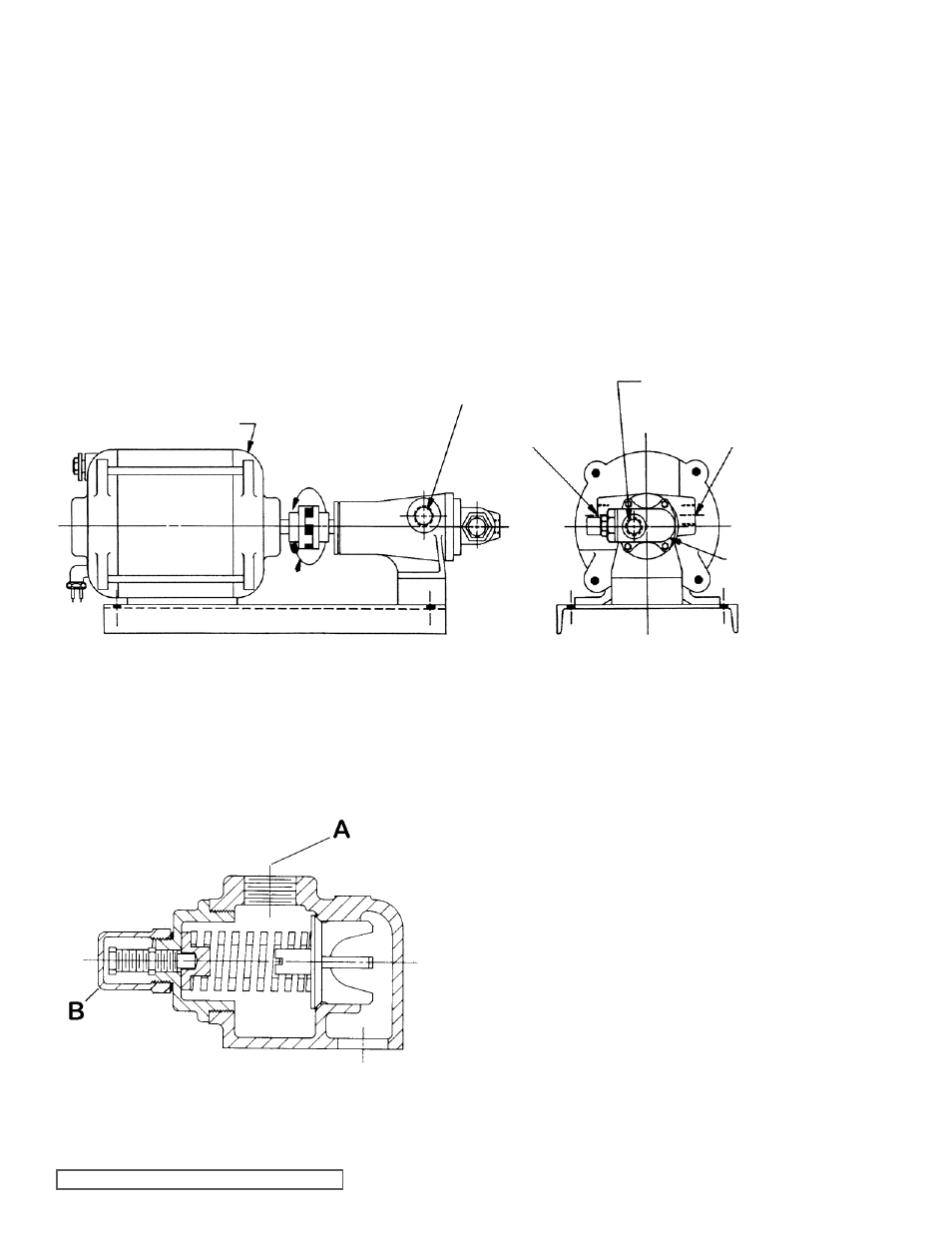

figure 8 illustrates your Viking pump unit with all its features

fIgURE 8

gg4195D-g LP-gaS PUMP UNIT

ELECTRIC MOTOR WITH UL

aPPROVaL fOR LP gaS

SERVICE 1750 RPM, ½ HP

REQUIRED fOR 75 PSI

bY-PaSS VaLVE SETTINg

* When viewing the unit from the motor end, looking toward

the pump, the correct pump rotation is clockwise and the

suction or inlet port is on the right

PORTS:

1” PIPE TaP

0.50” N.P.T. PRESSURE

RELIEf VaLVE CONNECTION

ROTaTION*

SUCTION

DISCHaRgE

RETURN-

TO-TaNk

PRESSURE

RELIEf VaLVE

A return-to-tank pressure relief valve (See Figure 9) is

mounted on the head end of the pump (See Figure 8) This

valve has 0 50” NPT connection for the return line (A on

Figure 9) The pump will not operate satisfactorily without

this return line being hooked up

The cap (B on Figure 9) of the pressure relief valve must

always point to the suction or inlet port of the pump If the

rotation of the pump shaft is reversed so that the flow through

the pump is reversed, then the pressure relief valve must be

removed, turned 180º and remounted

Normal setting for the pressure relief valve on the GG4195G

LP-Gas pump is 75 PSI (when a pressure gauge in the

discharge port reads 75 PSI higher than a pressure gauge

in the suction port, all of the liquid will be flowing through the

pressure relief valve back to the tank) Higher-pressure relief

valve settings are not encouraged, since they reduce pump

life, do not significantly speed up the transfer or filling rate

and often require a larger motor

fIgURE 9

RETURN-TO-TaNk PRESSURE RELIEf VaLVE

“gg” , “HJ” aND “HL” SIZE