Rp- 07 series (lip seal), Danger, Disassembly – Viking Pump TSM343.3: Vi-Corr Pumps User Manual

Page 9

DANgER!

Before opening any viking pump liquid chamber (pumping chamber, res-

ervoir, relief valve adjusting cap fitting etc.) Be sure:

1. That any pressure in chamber has been completely vented through

suction or discharge lines or other appropriate openings or

connections.

2. That the driving means (motor, turbine, engine, etc.) Has been “locked

out” or made non- operational so that it cannot be started while work is

being done on pump.

3. That you know what liquid the pump has been handling and the

precautions necessary to safely handle the liquid. Obtain a material

safety data sheet (MSDS) for the liquid to be sure these precautions are

understood.

Failure to follow above listed precautionary measures may result in seri-

ous injury or death.

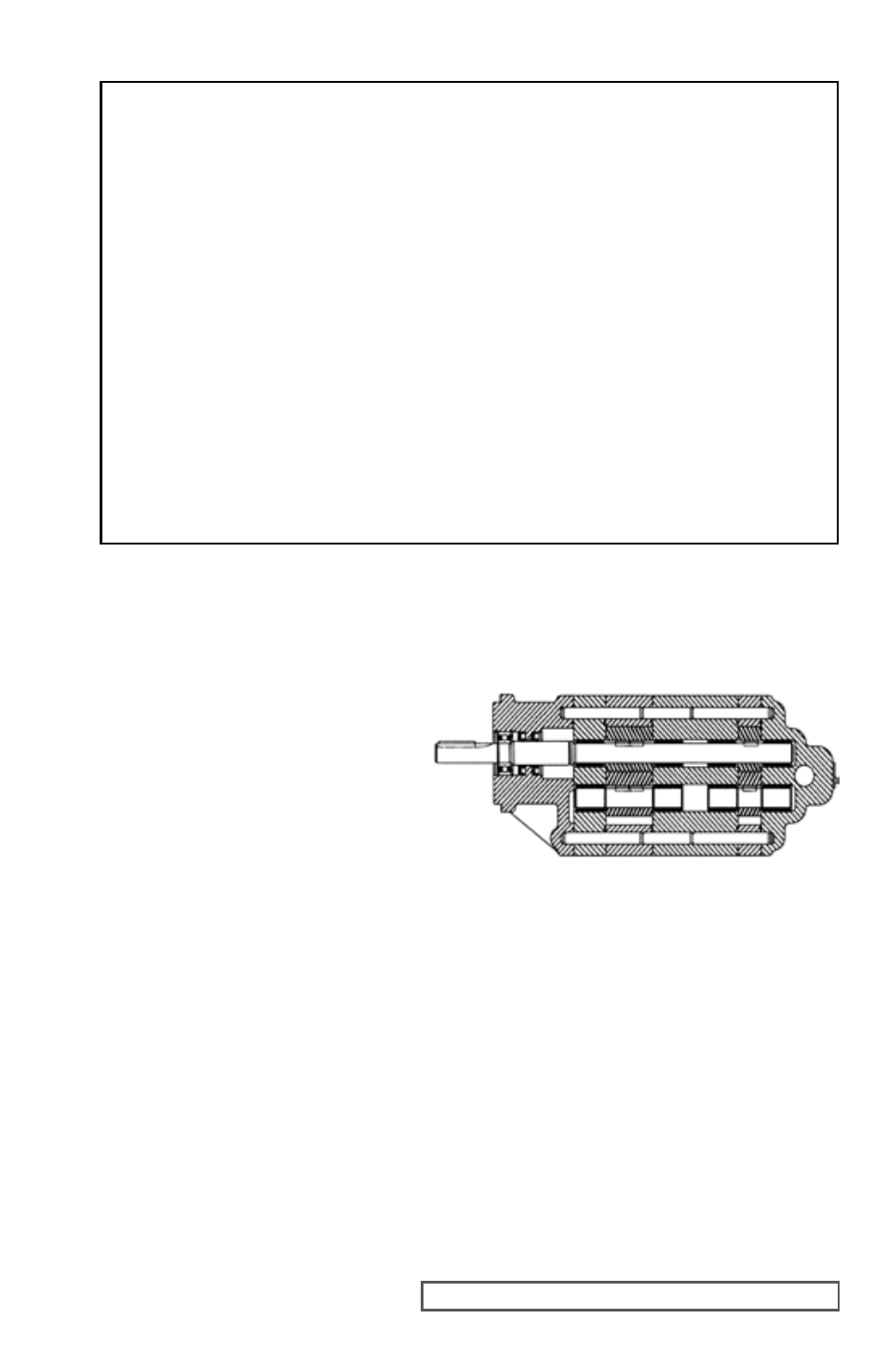

FIgURE 7

RP-0724 SECTIONAL vIEW

SECTION TSM

343.3

ISSUE

F

PAGE 9 OF 20

RP- 07 SERIES (LIP SEAL)

Disassembly:

1. Remove key from the driver shaft.

2. Remove the 4 assembly capscrews.

Remove snap ring on the drive shaft

in front of the bracket ball bearing.

Pump is now held together by the

alignment sleeves.

3. Hold the head of the pump and gently

tap on the sides of the pump bracket

with a soft hammer, alternating sides

of the pump. This should slowly

separate the sections. Note the

position of alignment sleeves for

assembly. Do not hit the sections

hard or use a screwdriver to pry them apart as this may damage the mating surfaces.

NOTE: If pump has 2 casing and gear sets (RP-0724) and (RP-0732),the casing and gears are

matched sets. Keep individual casing and gears together. See Figure 7.

4. After the pump is apart, inspect all parts for signs of wear. Look carefully at the shaft,

bushings, inside of the casing, gear teeth, lip seals, and the faces of the pump sections that

are located on each side of the casing for signs of wear.

5. If replacing the shafts, remove the retaining rings from both sides of the gear. Press the gear

off the shaft and remove drive pin(s) or balls from the shaft.

6. Check the bracket ball bearing for roughness. Roughness can be determined by turning the

inner race by hand. Replace if the bearing has roughness.