Danger – Viking Pump TSM310.1: C-FH 32/432 User Manual

Page 6

SECTION TSM 310.1

ISSUE

E

PAGE 6 OF 7

Be especially careful to keep mechanical seal parts clean.

Minute dirt particles, especially on seal faces, will cause

leakage. Never touch seal faces with anything except clean

hands or a clean cloth.

NOTE: The lapped face of the carbon wear ring must face

toward the shaft end of the pump. Be sure the notches on the

edge of the carbon wear ring mate with the retainer lugs in

the rotary member.

4. When reassembling a mechanically sealed pump, place

the spring washer and spring on the shaft,

see figure 5,

Page 4. Coat the shaft and the inside of the rubber

bellows of the seal rotary member with light oil. Slide the

rotary member part way down the shaft.

Oil the lapped faces of the rotary member and the seal seat.

Slide the seal seat on the shaft until it contacts the rotary

member and then push the complete seal into the casing.

Replace the packing nut and tighten.

Your pump is now completely assembled. Once again turn

the pump shaft by hand to be sure it turns freely. Start the

pump with a supply of liquid in the suction line, since the

pump should not be run dry.

5. If the pump has packing rather than a mechanical seal,

place the spring and inner packing gland on the shaft and

slide into the pump. Next install the packing. Stagger the

joints in the packing a half turn and add lube oil between

each ring of packing. Push the outer packing gland in the

casing, and replace the packing nut and tighten.

Viking pumps are positive displacement pumps and must

be provided with some sort of pressure protection. This may

be a relief valve mounted directly on the pump, an inline

pressure relief valve, a torque limiting device or a rupture

disk. Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure.

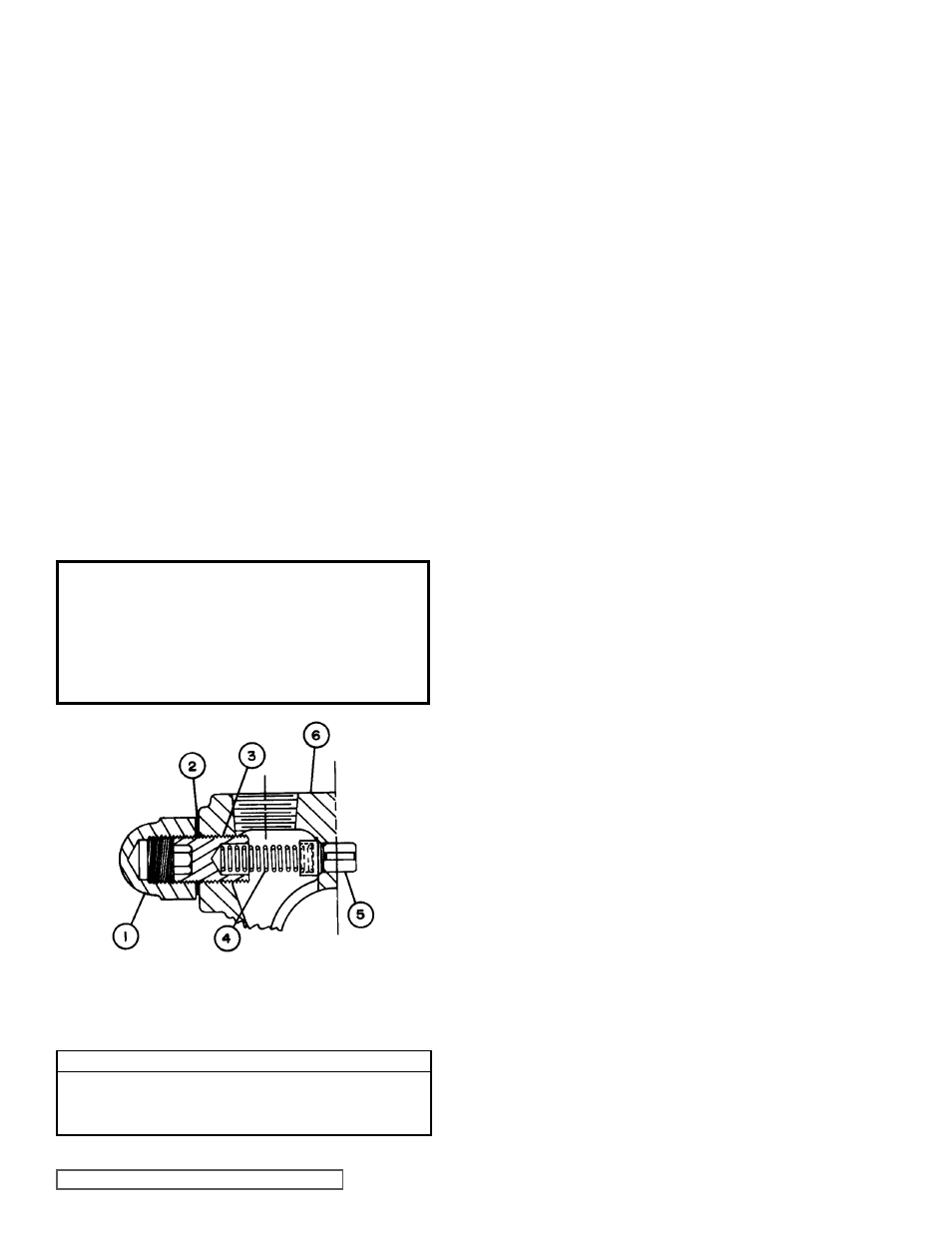

The pressure setting is increased by turning the adjusting

screw in and decreased by turning the adjusting screw out.

fIgURE 7

SAFETY RELIEF VALVE - C, F, FH SIZE

VaLVE - LIST Of PaRTS

1. Adjusting Screw Cap

4. Spring

2. Gasket for Cap

5. Poppet

3. Adjusting Screw

6. Casing

DaNgER !

Before starting pump, be sure all drive

equipment guards are in place.

failure to properly mount guards may

result in serious injury or death.

PRESSURE RELIEf VaLVE

INSTRUCTIONS

SPECIaL PUmP DESIgNS

Pumps furnished with a PTFE Mechanical seal require a

special rotor and shaft with drive pin installed for positive drive

of the rotating member. All other assembly and disassembly

instructions are the same.