Installing casing bushing, Assembly – Viking Pump TSM310.1: C-FH 32/432 User Manual

Page 5

SECTION TSM 310.1

ISSUE

E

PAGE 5 OF 7

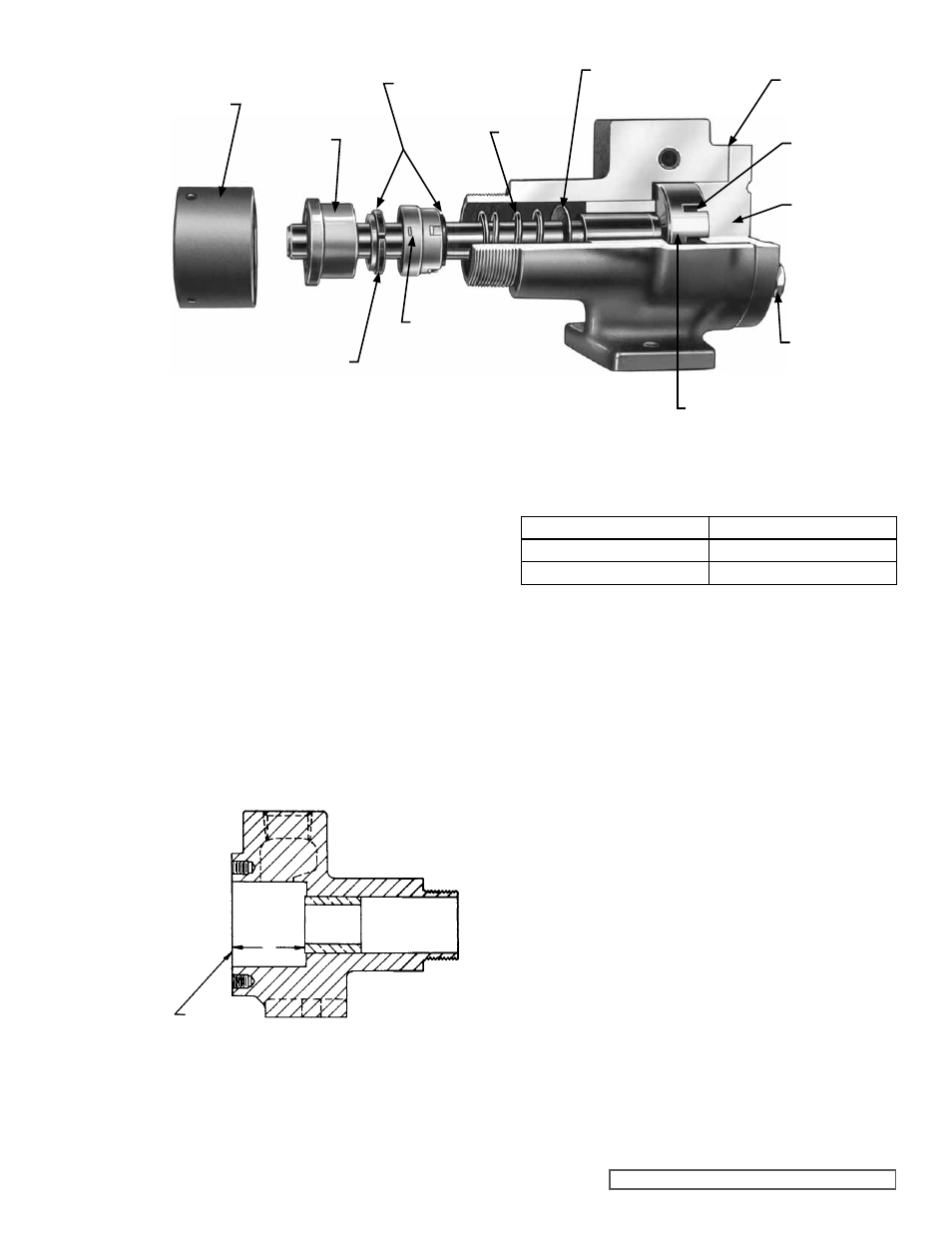

The casing bushing can be replaced in the following manner:

Insert a bar approximately 0.94” diameter and at least 3.5”

long in the packing or seal end of the casing and press the

bushing out of the casing.

When installing a new carbon graphite bushing, extreme

care should be taken to prevent breakage as carbon graphite

is a brittle material and easily cracked. When cracked the

bushing may quickly disintegrate in operation. An arbor press

should always be used and the bushing should be installed in

one even uninterrupted stroke of the press. Dip the bushing

in lube oil and start the bushing in the head end of the casing.

Press until located to the “A” dimension in

figure 6.

INSTaLLINg CaSINg BUSHINg

fIgURE 5

fIgURE 6

The end clearance within the pump is governed by the location

of the casing bushing as well as the number of head gaskets.

To correctly position the casing bushing in the casing, see

note in step 3 of

aSSEmBLY.

PUmP SIZE

“a” DImENSION

C

0.88” to 0.94”

F & FH

1.19” to 1.25”

1. Clean all parts thoroughly.

2. Place the rotor and shaft in the casing.

3. Put the head gaskets on the head and the idler on the

idler pin projecting from the head. Replace the head in

the casing; tighten the cap screws.

NOTE: If a new casing bushing has been installed in the

casing, use only one .002” head gasket on the head and

tighten the capscrews evenly and securely. This will correctly

position the bushing in the casing. Remove the head, add

one .002” head gasket and replace the capscrews and tighten

securely.

NOTE: Turn the shaft by hand to be certain it turns freely.

aSSEmBLY

IDLER

SPRINg

PaCKINg NUT

HEaD aND

IDLER PIN

HEaD

CaPSCREWS

CaRBON WEaR RINg

SPRINg WaSHER

HEaD gaSKETS

RETaINER LUg

ROTaRY

mEmBER

ROTOR aND SHafT

SEaL SEaT

HEaD

faCE

A