Pressure relief valve instructions, Thrust bearing adjustment, Assembly – Viking Pump TSM212: H-LL 724/4724 User Manual

Page 8: Danger

SECTION TSM 212

ISSUE

F

PAGE 8 OF 9

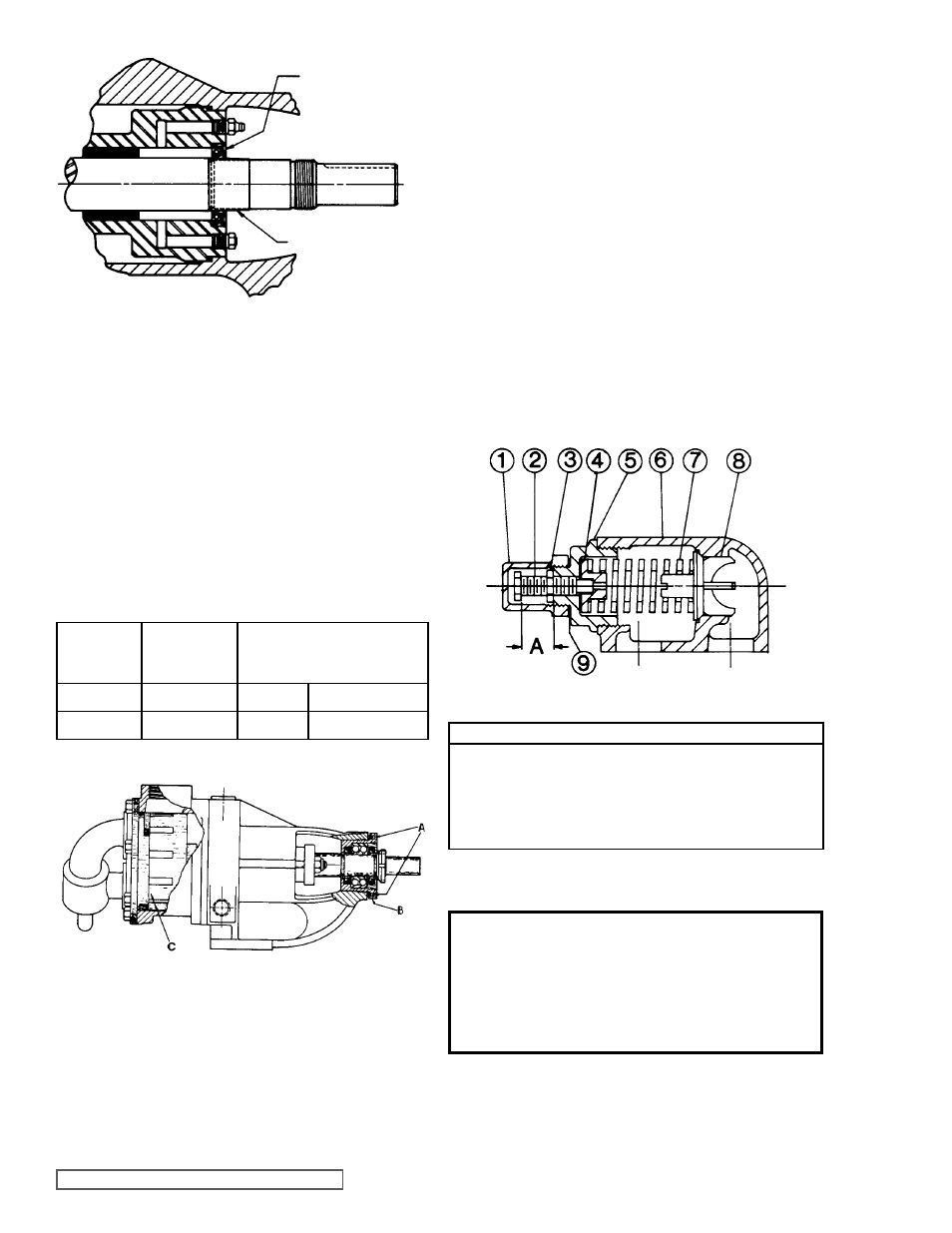

fIgURE 11

VALVE - LIST Of PARTS

1. Valve Cap

6. Valve Body

2. Adjusting Screw

7. Valve Spring

3. Lock Nut

8. Poppet

4. Spring Guide

9. Cap Gasket

5. Bonnet

PRESSURE RELIEf VALVE

INSTRUCTIONS

1. Remove valve cap.

2. Measure and record the length of extension of the

adjusting screw,

See (A) figure 11.

3. Loosen the lock nut and back out adjusting screw until

spring pressure is released.

4. Remove bonnet, spring guide, spring and poppet from

valve body. Clean and inspect all parts for wear or

damage and repair or replace as necessary.

THRUST BEARINg ADJUSTMENT

(See figure 10)

1. Loosen the two set screws “A” in the outer face of the

bearing housing “B” and turn this thrust bearing assembly

“B” clockwise until it can no longer be turned by hand.

Back off counterclockwise only until the rotor shaft can

be turned by hand with a slight noticeable drag.

2. For standard end clearance, back off the thrust bearing

assembly “B” the required number of notches or an

equivalent length measured on the outside of the bearing

housing. See the following table.

fIgURE 9

fIgURE 10

ASSEMBLY

Reverse the procedure outlined under

DISASSEMBLY.

If valve is removed for repairs, be sure to replace in same

position. The valve cap should point towards the suction

port.

4. High viscosity and high temperature liquids require

additional end clearances. The amount of extra end

clearance depends on the viscosity or temperature of the

liquid pumped. For specific recommendations, consult

the factory. Each additional notch (or each 1/4”) on the

outside diameter of the bearing housing is equivalent to

an extra end clearance of .002” on H & HL size pumps;

and .0015” on K, KK, L, LQ and LL pumps.

End

Clearance

PUMP

SIZE

TURN BEARINg HOUSINg

C.C.W. NO. Of NOTCHES OR

LENgTH ON O.D., INCHES

.005”

H, HL

2.5

0.6” or 5/8”

.008”

K, KK, LQ & LL

5.5

0.35” or 1-3/8”

TAPERED SLEEVE

LIPSEAL fOR

SEAL CHAMBER

3. Tighten the two self locking type “Allen” set screws “A,”

in the outboard face of the bearing housing, with equal

force against the bracket. Your pump is now set with

standard end clearances and locked.

NOTE: Be sure the

shaft can rotate freely. If not, back off additional notches

and check again.

DANgER !

Before starting pump, be sure all drive

equipment guards are in place.

failure to properly mount guards may

result in serious injury or death.