Disassembly – Viking Pump TSM212: H-LL 724/4724 User Manual

Page 5

SECTION TSM 212

ISSUE

F

PAGE 5 OF 9

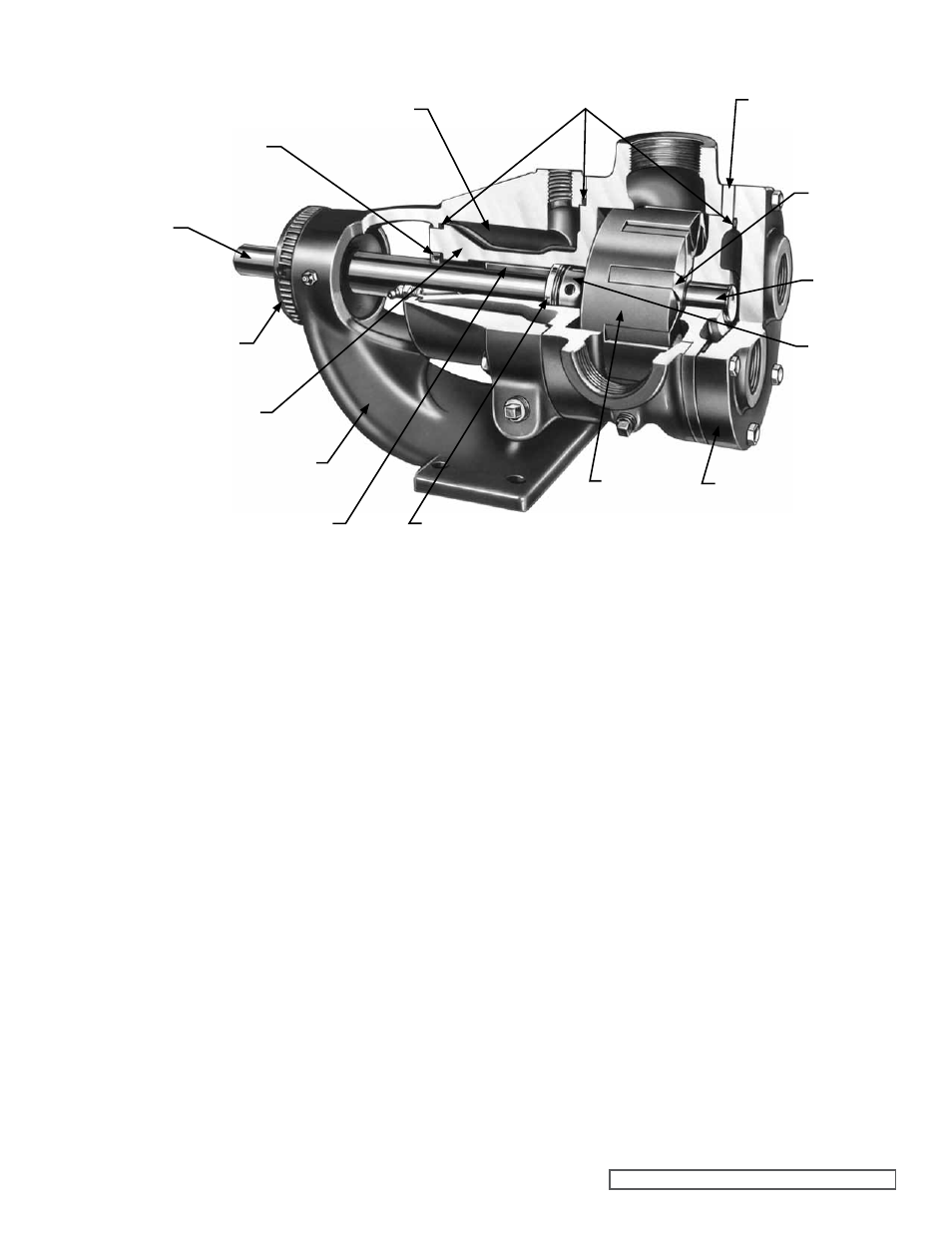

SHAfT

LIPSEAL

STEAM JACKETED

AREA

HEAD

IDLER

IDLER PIN

SEAL

ROTATINg

MEMBER

STEAM JACKETED

HEAD PLATE

ROTOR

SEAL

STATIONARY MEMBER

CASINg

BRACKET

CASINg BUSHINg

BEARINg

HOUSINg

DISASSEMBLY

fIgURE 4

1. Remove the head from the pump.

CAUTION: DO NOT ALLOW THE IDLER TO fALL

fROM THE IDLER PIN. Tilting the head up as it is

removed will prevent this occurrence. Avoid damaging

the head gasket if possible. If pump is furnished with

a relief valve it need not be removed from head or

disassembled at this point.

(See page 6 for PRESSURE

RELIEf VALVE INSTRUCTIONS). If the pump has a

steam jacket head plate, this plate will separate from

the head when the head is removed from the pump. The

compression O-ring between the head and the jacket

head plate should be removed and the gasket surfaces

on the above parts cleaned.

Note: These pumps also have a steam jacket feature

incorporated into the casing and bracket assembly. To

avoid destroying the sealing on this steam jacket the

casing should not be removed from the mounting bracket

when the pump is disassembled for maintenance.

If the pump is equipped with a jacketed head plate,

disassembly will probably require replacement of the

O-ring between the pump head and jacket head plate.

These O-rings should be carried as spare parts for

pumps thus equipped.

2. Remove the idler and bushing assembly from the idler

pin. Replace all excessively worn parts. See

CAUTION

about replacement of carbon bushings in Step 12.

3. NOTE: A piece of wood or brass inserted between the

rotor teeth and into the casing port will prevent the shaft

from turning. Bend up tang on lockwasher and, using a

spanner wrench, remove the lockwasher and locknut.

4. Loosen packing gland nuts on series 724 pumps. Drive

the shaft forward approximately 0.5 inch and inspect for

presence of a pair of half round rings under the inner

bearing spacer collar (K-LL only). If present, these rings

must be removed before the rotor and shaft can be

removed from the pump.

5. Carefully remove the rotor and shaft assembly from the

pump. NOTE: Avoid damaging the bracket bushing.

The rotary portion of the mechanical seal will usually

come out with the shaft on series 4724 pumps. Remove

the stationary seal seat from the bracket counterbore.

Replace rotor and shaft assembly if excessively worn.

O-RINgS