Thrust bearing adjustment – Viking Pump TSM154: GG-AL 493/4193 User Manual

Page 8

SECTION TSM 154

ISSUE

D

PAGE 8 OF 10

Loosen two screws in face of thrust bearing assembly.

If shaft cannot be rotated freely, turn thrust bearing assembly

counterclockwise until shaft can be turned easily.

To set end clearance:

1. While turning rotor and shaft assembly, rotate thrust

bearing assembly clockwise until noticeable drag occurs.

This is zero end clearance.

2. Mark position of bearing housing with respect to the

casing.

3. Rotate thrust bearing assembly counterclockwise the

distance listed below as measured on outside of bearing

housing.

4. Tighten two setscrews in face of bearing housing after

adjustment is made to secure thrust bearing assembly

position.

For viscosities above 2500 SSU, add additional end

clearance (0.005” for GG, HJ and HL size pumps and

0.007” for AS, AK and AL size pumps).

When installing carbon graphite bushings, extreme care

must be taken to prevent breaking. Carbon graphite is a

brittle material and easily cracked. If cracked, the bushing will

quickly disintegrate. Using a lubricant and adding a chamfer

on the bushing and the mating part will help in installation.

The additional precautions listed below must be followed for

proper installation:

1. A press must be used for installation.

2. Be certain bushing is started straight.

3. Do not stop pressing operation until bushing is in proper

position, starting and stopping may result in a cracked

bushing.

4. Check bushing for cracks after installation.

THRUST bEARINg ADJUSTMENT

See figures 9 and 10.

PUMP

SIZE

DISTANCE IN INCHES

ON O.D. Of bEARINg

HOUSINg

END

CLEARANCE

GG

7/16”

0.003”

HJ, HL

9/16”

0.003”

AS, AK, AL

1/2”

0.003”

INSTALLATION Of CARbON

gRAPHITE bUSHINgS

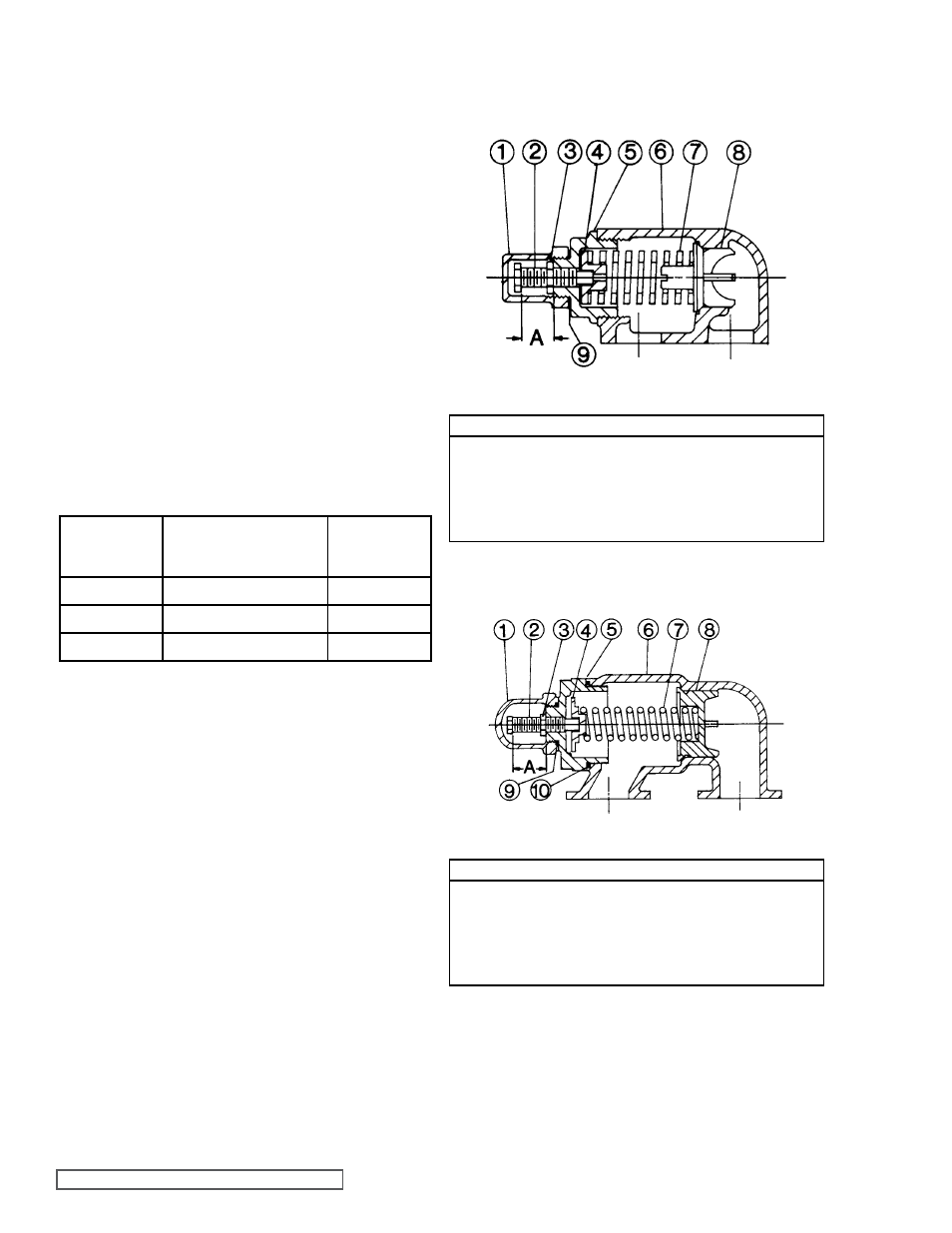

PRESSURE RELIEf VALVE

INSTRUCTIONS

fIgURE 13

VALVE - LIST Of PARTS

1. Cap

6. Valve Body

2. Adjusting Screw

7. Spring

3. Lock Nut

8. Poppet

4. Spring Guide

9. Cap Gasket

5. Bonnet

VALVE - LIST Of PARTS

1. Cap

6. Valve Body

2. Adjusting Screw

7. Spring

3. Lock Nut

8. Poppet

4. Spring Guide

9. Cap

5. Bonnet

10. Bonnet

VALVE - gg, HJ and HL SIZES

VALVE - AS, AK and AL SIZES

fIgURE 14