Disassembly – Viking Pump TSM154: GG-AL 493/4193 User Manual

Page 4

SECTION TSM 154

ISSUE

D

PAGE 4 OF 10

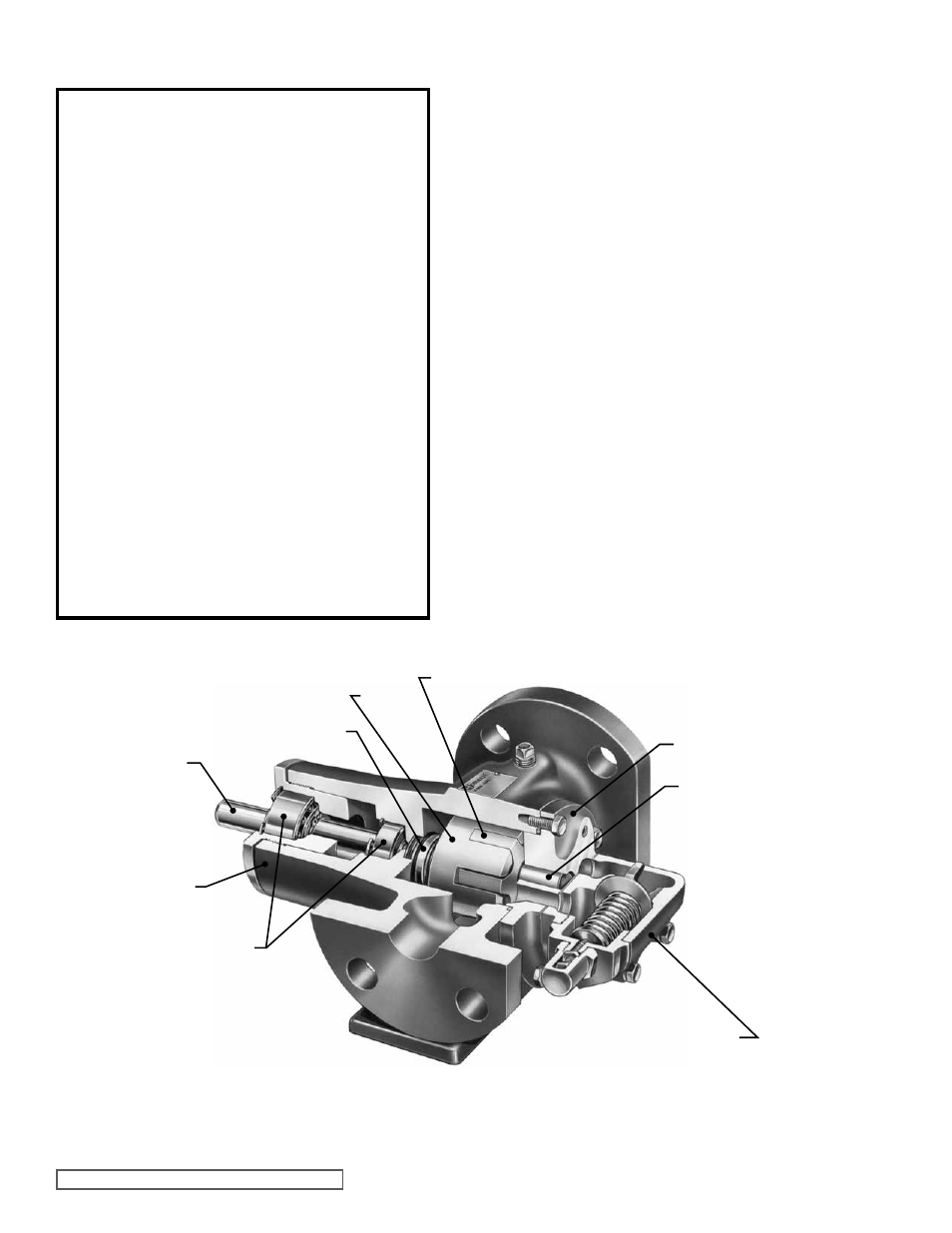

fIgURE 6

CUTAWAY fOR MODELS gg, HJ AND HL4193

CASINg

DISASSEMbLY

DANgER !

before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

failure to follow above listed

precautionary measures may result in

serious injury or death.

1. Refer to figures 7 & 8 on page 4 for model to be

disassembled and name of parts. Models 4193 & 493 are

disassembled and assembled the same. The difference

between these models is the casings.

2. Mark

the head and casing before disassembly to ensure

proper reassembly.

3. NOTE: The four valve capscrews, valve and gasket

must be removed from the GG 4193-493 model before

the six head capscrews are removed.

Remove the head capscrews.

4. Remove the head from the pump. Do not allow the idler

to fall from the idler pin. Tilt the top of the head back

when removing to prevent this. Avoid damaging the

head gasket.

5. Remove the idler and bushing assembly. If the the idler

bushing needs replacing,

see “Installation of Carbon

graphite bushings”, page 7.

6. Remove the locknut from the shaft. See figure 9 or 10.

A brass bar or piece of hardwood inserted in the port

opening and between the rotor teeth will keep the shaft

from turning.

7. Loosen the two setscrews in the face of the bearing

housing and turn the thrust bearing assembly

counterwise and remove from the casing.

See figure

9 or 10.

8. Remove

the snap ring from the shaft for GG, HJ and HL

size pumps.

See figure 9.

9. Remove

the bearing spacer from the shaft for AS, AK

and AL size pumps. See Figure 10.

10. Remove the brass bar or piece of hardwood from the

port opening.

ROTOR

IDLER

HEAD

CASINg

SHAfT

IDLER PIN

RELIEf VALVE

MECHANICAL SEAL

bALL bEARINgS