Danger – Viking Pump TSM154: GG-AL 493/4193 User Manual

Page 7

SECTION TSM 154

ISSUE

D

PAGE 7 OF 10

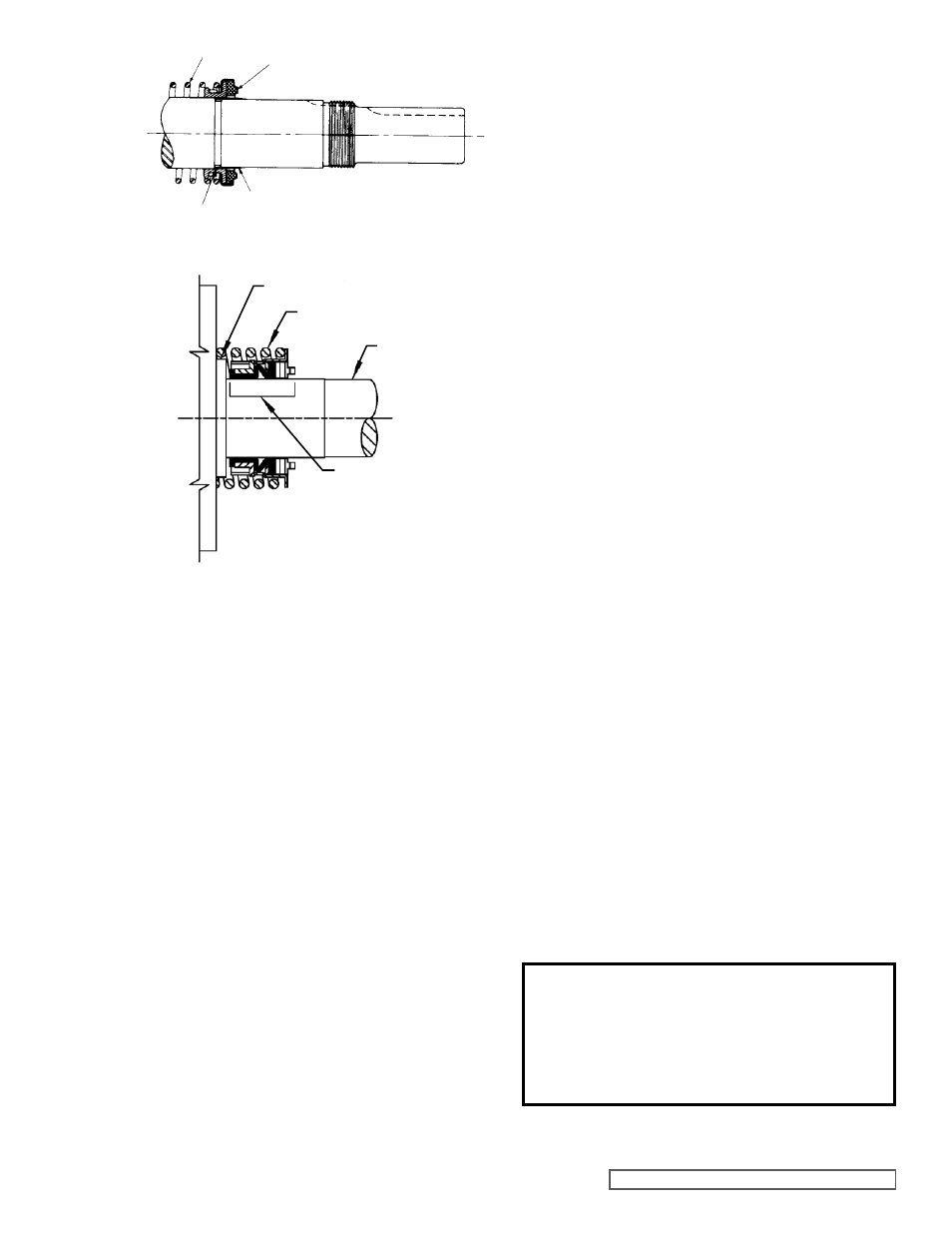

4. Place tapered installation sleeve on shaft, refer to

figure 11. Sleeve is furnished with GG, AS, AK and AL

size replacement mechanical seals. Coat rotor and shaft

assembly, tapered installation sleeve and inner diameter

of mechanical seal rotary member with a generous

amount of non-detergent SAE 30 weight oil. Petrolatum

may be used but grease is not recommended.

5. Place seal spring on shaft against rotor hub. Refer to

figure 12.

6. Slide rotary member, lapped contact surface facing away

from spring, over installation sleeve on shaft until it is

against the spring.

7. Do not compress the spring.

8. Coat the rotor and shaft assembly with non-detergent

SAE 30 weight oil. Taking care not to damage the seal

seat, start end of shaft in bracket bushing and turn from

right to left, slowly pushing until the ends of the rotor

teeth are just below the face of the casing.

9. Leave the rotor in this position. Withdrawal of rotor and

shaft may displace the carbon seal rotating face and

result in damage to the seal.

10. Place O-ring gasket on head and install head and idler

assembly on pump. Pump head and casing were marked

before disassembly to ensure proper reassembly. If

not, be sure idler pin, which is offset in pump head,

is positioned toward or equal distance between port

connections to allow for proper flow of liquid through

pump.

DANgER !

before starting pump, be sure all drive

equipment guards are in place.

failure to properly mount guards may

result in serious injury or death.

fIgURE 11

SPRINg

MECHANICAL SEAL

(ROTARY MEMbER)

TAPERED SLEEVE

COAT WITH LIgHT OIL bEfORE ASSEMbLY

MECHANICAL SEAL

(ROTARY MEMbER)

SPRINg

ROTOR HUb

SHAfT

fIgURE 12

11. Tighten head capscrews evenly.

12. If pump was equipped with a relief valve and was

removed during disassembly, install with new o-rings or

gaskets. Relief valve adjusting screw cap must always

point towards suction port.

Refer to figure 5, page 2.

For relief valve repair or adjustments,

see PRESSURE

RELIEf VALVE INSTRUCTIONS, Page 7.

13. In 2005, the use of single seal bearings were phased

out. Pumps now use “Sealed for Life” bearings that

have seals on both sides. The new bearings can be

installed either side first and do not need to be packed

with grease. For older models with single seal bearings,

pack the inner ball bearing with multi-purpose grease,

NLGI #2

NOTE: AS, AK and AL size pumps do not have a snap

ring, a bearing retainer washer must be assembled over

end of shaft before the bearing is assembled.

See figure

10.

14. Place bearing spacer over shaft and against single row

ball bearing in casing (AS, AK and AL size pumps).

See

figure 10.

Install snap shaft ring in groove in the shaft (GG, HJ and

HL size pump.

See figure 8.

15. Pack lubrication chamber between inner ball bearing and

double row ball bearing in the thrust bearing assembly

approximately half full with multi-purpose grease,

NLGI#2.

See figures 9 and 10.

16. Pack double row ball bearing with multi-purpose grease,

NLGI#2 and press into bearing housing with shield side

toward coupling end of shaft.

See figure 9. (AS, AK and

AL size pumps do not use a shielded bearing). Install

snap ring to hold bearing in place on GG, HJ and HL size

pumps.

NOTE: On AS, AK and AL size pumps, install lip seal in

bearing house end cap. The lip should face towards end

of shaft. Put bearing spacer sleeve in lip seal and install

in bearing housing and tighten setscrews securely.

See

figure 20.

17. Insert a piece of brass or hard wood through port opening

between rotor teeth to keep shaft from turning.

18. Start thrust bearing assembly into casing. Turn by hand

until tight. This forces rotor against head. Replace and

tighten locknut on shaft.

19. Remove brass piece or hardwood from port opening.

Adjust pump end clearance,

refer to page 7.