Troubleshooting, Rapid wear – Viking Pump TSM000: General Information User Manual

Page 6

SECTION TSM 000

ISSUE

I

PAGE 6 OF 8

A Viking pump that is properly installed and maintained will give long

and satisfactory performance

NOTE: Before making any pump adjustment or opening the pump

liquid chamber in any manner, make sure that:

1. any pressure in the pumping chamber has been vented through

the suction or discharge lines or other openings provided for

this purpose,

2. the driver has been “locked out” so that it cannot inadvertently

be started while work is being done on the pump and

3. the pump has been allowed to cool down to the point where

there is no chance of anyone being burned

If trouble does develop, one of the first steps toward finding the

difficulty is to install a vacuum gauge in the suction port and a

pressure gauge in the discharge port Readings on these gauges

often will give a clue as to where to start looking for the trouble

TrOubLEShOOTiNg

vacuum gauge - Suction port

1. high reading would indicate -

a) Suction line blocked - foot valve stuck, gate valve closed,

strainer plugged

b) Liquid too viscous to flow through the piping

c) Lift too high

d) Line too small

2. Low reading would indicate -

a) Air leak in suction line

b) End of pipe not in liquid

c) Pump is worn

d)

Pump is dry - should be primed

3. fluttering, jumping, or erratic reading -

a) Liquid vaporizing

b) Liquid coming to pump in slugs, possibly an air leak

insufficient liquid above the end of the suction pipe

c) Vibrating from cavitation, misalignment, or damage parts

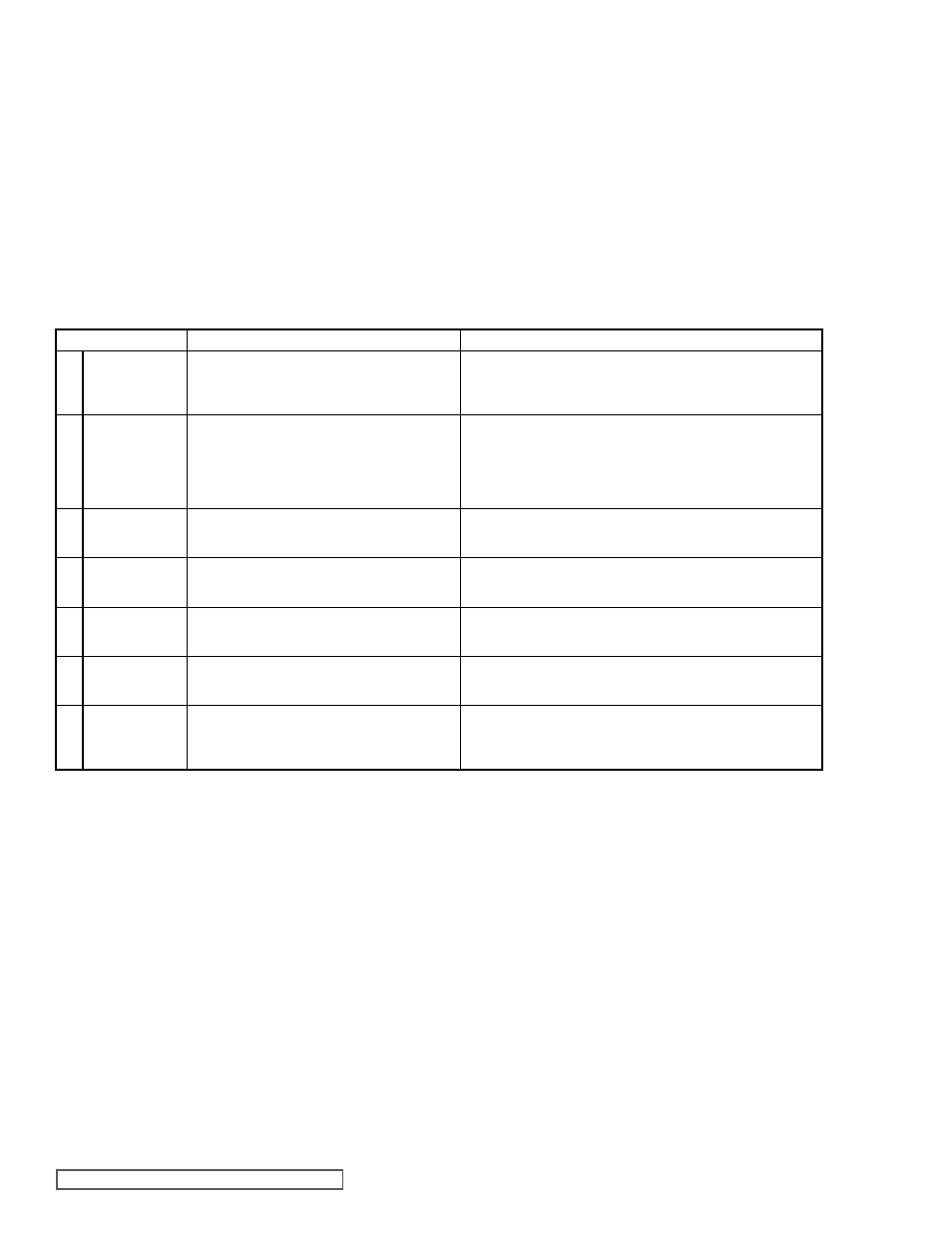

rApid wEAr

CAuSE

EvidENCE

pOSSibLE SOLuTiON

1.

AbrASivES

Gouges or marks made by large, hard particles;

a rapid wearing away of bushings from very

small abrasives similar to pumice; or anything in

between

Flush the system with the pump removed Install strainer in suction

line Oftentimes after a system has run for a few cycles or a few days,

the dirt is pretty well cleaned out and if the pump is rebuilt into good

condition, it will then last for a long time

2.

COrrOSiON

Rust, pitting or metal appears to be “eaten” away

Check the Viking General Catalog Liquid List for materials of

construction recommendation Consider weather all of the materials

used in pump construction were attacked; consider other materials

used in the system to determine how they resisted the liquid Check

to see weather or not the liquid has been contaminated to make it

more corrosive than anticipated

3.

EXCEEdiNg

OpErATiNg

LiMiTS

Noisy operation, broken bushings, twisted shaft,

parts show evidence of high heat (discoloration)

Review General Catalog for operating limits on particular model

involved

4.

iNSuffiCiENT

EXTrA

CLEArANCE

Pump may stall Evidence of heavy contact between

end of rotor teeth and head or other parts

Increase end clearance and/or contact you distributor or the factory

with details of the application so that information regarding proper

extra clearance may be provided

5.

LACk Of

LubriCATiON

Noisy bearings, localized heating at bearings or lip

seal, smoke, rapid bushing wear

Be sure all grease fittings are greased before starting and instructions

for lubrication of drive equipment are followed; consider use of

auxiliary lubricating equipment

6.

MiSALigNMENT Wear on only one part of a surface, e g , one side

of the casing, one side of the packing gland, only a

portion of the face of the head

Double check alignment of drive equipment and piping Check the

alignment under conditions as close to operating conditions as

possible

7.

ruN dry

Pump stalls because parts have uneven expansion

caused by frictional heat; galling between surfaces

having relative motion; seal seats and idler pins

changing color because of high heat

Be sure there is liquid in the system at the time of start up Provide

some kind of automatic alarm or shut-off if supply tank runs dry

13. Now you are ready to push the “start” button - gently

If the pump begins to deliver liquid within 60 seconds, you’re

in business If it does not, push the “stop” button Do

not run the

pump longer than one minute without liquid in it; you may damage

it Review the steps just outlined, consider what the suction and

discharge gauges indicate,

see page 6; if everything appears to be

in order, put some liquid in the pump, a lubricating liquid is best This

will help it prime

Push the “start” button again If nothing is flowing within two minutes,

stop the pump The pump is not a compressor, it will not build up

much air pressure; it may be necessary to vent the discharge line

until liquid begins to flow

If the pump still does not deliver, the cause may be one or more of

the following:

1.

Suction line air leaks; vacuum gauge reading should help

determine if this is the problem

2. End of suction pipe not submerged deep enough in liquid

3.

Suction lift is too great or the suction piping is too small

4.

Liquid is vaporizing in the suction line before it gets to the

pump

if after consideration of these points it still does not pump,

suggest you review again all points given under STArT up;

read through Troubleshooting in this manual and try again. if it

still does not pump, contact your viking representative.