Piping, Ab c d – Viking Pump TSM000: General Information User Manual

Page 4

SECTION TSM 000

ISSUE

I

PAGE 4 OF 8

3. If the pump is driven by V-belts, check the alignment by using a

long straightedge or tightly drawn string across the face of the

sheaves

See figure 6A.

4. Make a final check on alignment after piping is hooked up

See item 13 under

“installation - piping.

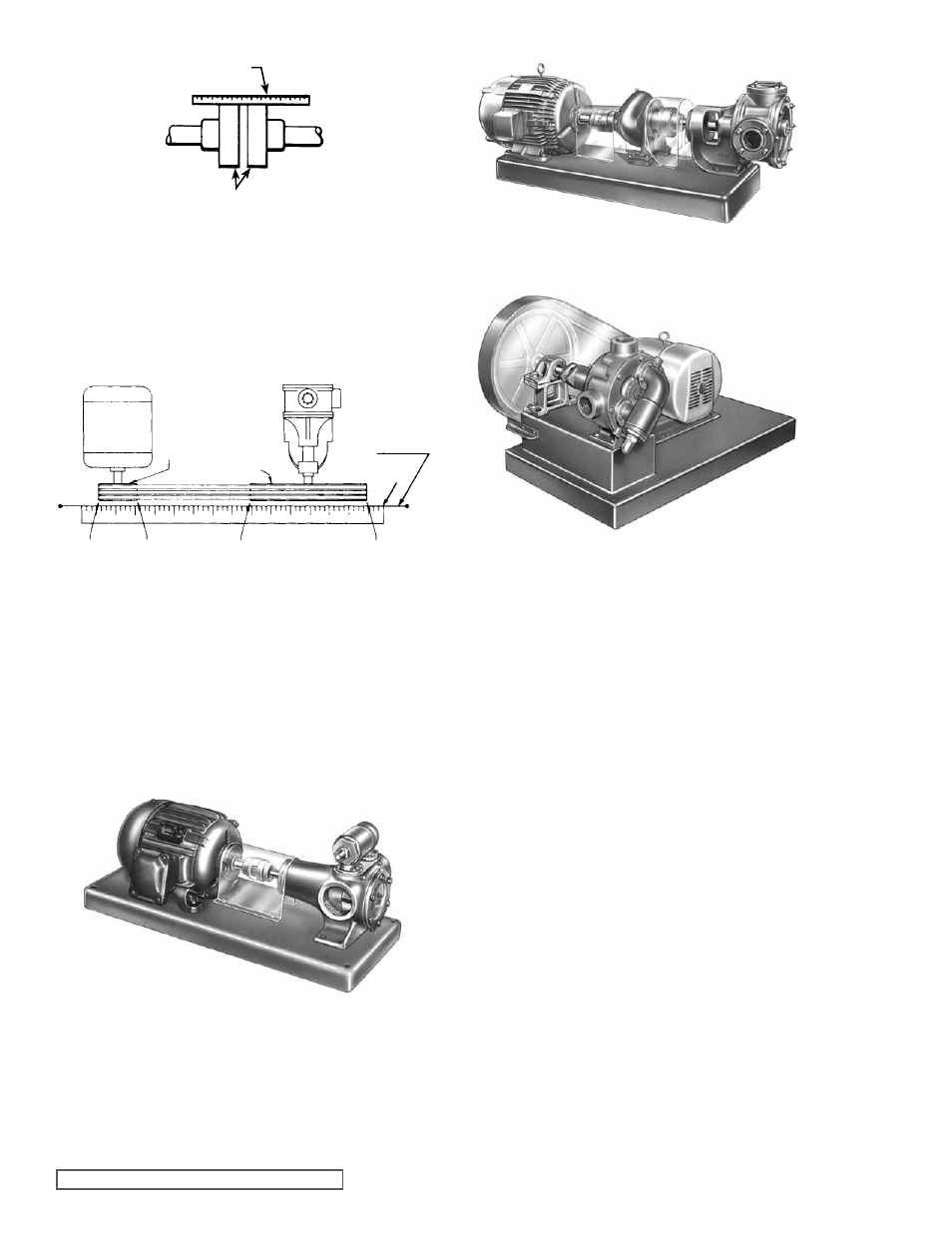

figures 7, 8, and 9 show typical units - direct, gear

reducer and V-belt drive

5. For high temperature applications (those above 300°F) allow the

pump to reach operating temperature, then recheck alignment

figurE 6

figurE 6A

figurE 7

dirECT drivE

figurE 8

rEduCEr drivE

figurE 9

v-bELT drivE

The cause of many pumping problems can be traced to suction

piping It should always be as large and short as practical For help

in selecting the proper size piping, both suction and discharge,

refer

to viking general Catalog Section 510.

Before starting layout and installation of your piping system, consider

the following points:

1. Never use piping smaller than the pump port connections

2. Be sure the inside of the pipe is clean before hooking it up

3. Foot valve - When pumping a light liquid with a suction lift, a

foot valve at the end of the suction piping or a check valve in

the first horizontal run will hold the liquid in the line and make it

easier for the pump to prime Be sure the foot or check valve is

big enough so that it doesn’t cause excessive line loss

4. When approaching an obstacle in the suction or discharge line,

go around the obstacle instead of over it Going over it creates

an air pocket

See figure 10.

5. Where practical, slope the piping so no air or liquid pockets will

be formed Air pockets in the suction line make it hard for the

pump to prime

6. For a suction line with a long horizontal run keep the horizontal

portion below the liquid level if possible This keeps the pipe

full so the pump does not have to remove so much air when

starting; this is most helpful when there is no foot valve

See

figure 11.

7.

When piping a hot or cold system (liquid being handled is at a

temperature different from the air surrounding the pump), be

sure allowance is made for expansion and contraction of the

piping Loops, expansion joints, or unsecured (this does not

mean unsupported) runs should be used so the pump casing is

not distorted or put into a bind

pipiNg

ChECk widTh bETwEEN ThESE SurfACES wiTh

iNSidE CALipErS TO bE CErTAiN ThE fACES ArE

EquAL diSTANCE ApArT ANd pArALLEL.

uSE A STrAighT EdgE. ThESE

SurfACES MuST bE pArALLEL.

drivEr

ShEAvE drivEN

ShEAvE

STriNg

Or

STrAighT EdgE

a

b

C

D

whEN ShEAvES ArE prOpErLy ALigNEd, ALL pOiNTS

A, b, C, d wiLL TOuCh STriNg Or STrAighT EdgE.