Stainless steel 30a n, Plasma / h, O shield – Tweco XT-300 Torch Data for OEM Ultra-Cut 150 & 200 Power Supply AJ User Manual

Page 11

Manual 0-4802 Rev. AJ

8-11

TORCH DATA

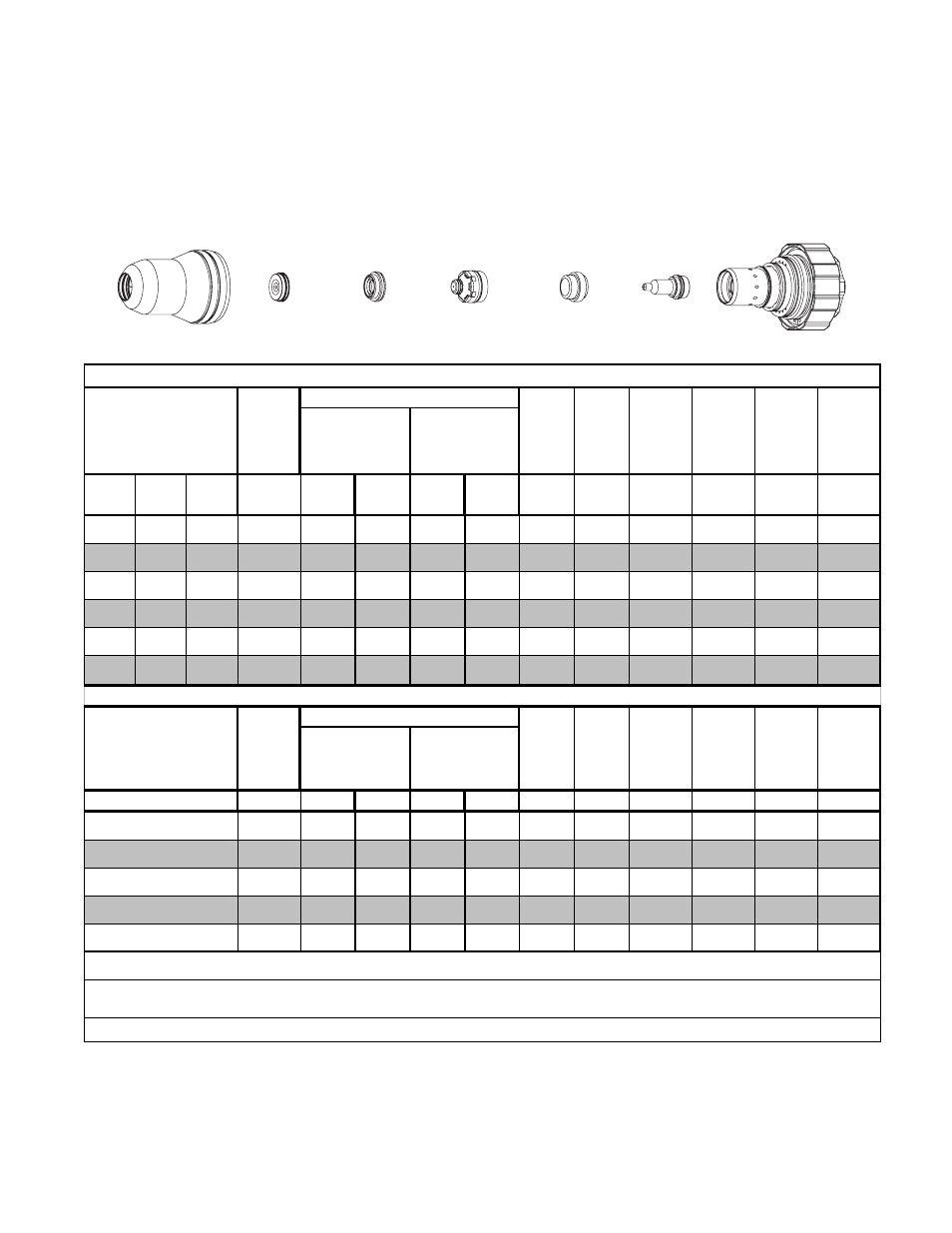

Stainless Steel

30A

N

2

Plasma / H

2

O Shield

Cartridge

22-1020

Electrode

22-1077

Plasma

Gas Distributor

22-1045

Tip

22-1059

Shield Cap

22-1033

Shield Cup

22-1016

Art # A-06042

Shield

Gas Distributor

22-1274

(ga)

(in)

(in)

(psi)

Ball

(psi)

Ball

(psi)

(volts)

(in)

±0.005

(ipm)

(in)

(sec)

(in)

26

0.019

90

75

120

4

55

91

0.020

600

0.040

0.0

0.047

24

0.025

90

64

120

4

55

97

0.020

440

0.040

0.0

0.045

22

0.031

90

50

120

4

55

95

0.020

420

0.040

0.0

0.045

20

0.038

90

60

120

5

55

105

0.020

300

0.050

0.1

0.044

18

0.050

90

60

120

5

55

78

0.030

250

0.050

0.1

0.035

16

0.063

90

60

120

5

55

85

0.050

205

0.060

0.2

0.044

(bar)

Ball

(bar)

Ball

(bar)

(volts)

(mm)

(mm/min)

(mm)

(sec)

(mm)

6.2

75

8.3

4

3.8

96

0.5

12110

1.0

0.0

1.2

6.2

64

8.3

4

3.8

96

0.5

10450

1.0

0.0

1.1

6.2

50

8.3

4

3.8

102

0.5

7470

1.3

0.1

1.1

6.2

60

8.3

5

3.8

83

1.0

5550

1.4

0.2

1.0

6.2

60

8.3

5

3.8

93

2.0

3820

1.8

0.3

1.4

NOTE 2: Water source used for H

2

O Water Shield must be demineralized.

NOTE 1: Ohmic height sensing is not recommended with water shield.

Water on the plate interferes electrically with the ohmic sensing circuit.

1.5

2.0

Pressure of the water supply line should be regulated by customer-supplied pressure regulator.

(mm)

0.6

0.8

1.0

** Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Plasma (N

2

)

Shield (H

2

O)

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates / Pressures

Pierce

Delay

Kerf

Width

@ Rec.

Speed

Plasma (N

2

)

Shield (H

2

O)

30A Stainless Steel N

2

/H

2

O

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates / Pressures

** Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf

Width

@ Rec.

Speed