Mild steel 30a o, Plasma / o, Shield – Tweco Torch Data User Manual

Page 3

Manual 0-4730 Rev. AF

8-3

TORCH DATA

Mild Steel

30A

O

2

Plasma / O

2

Shield

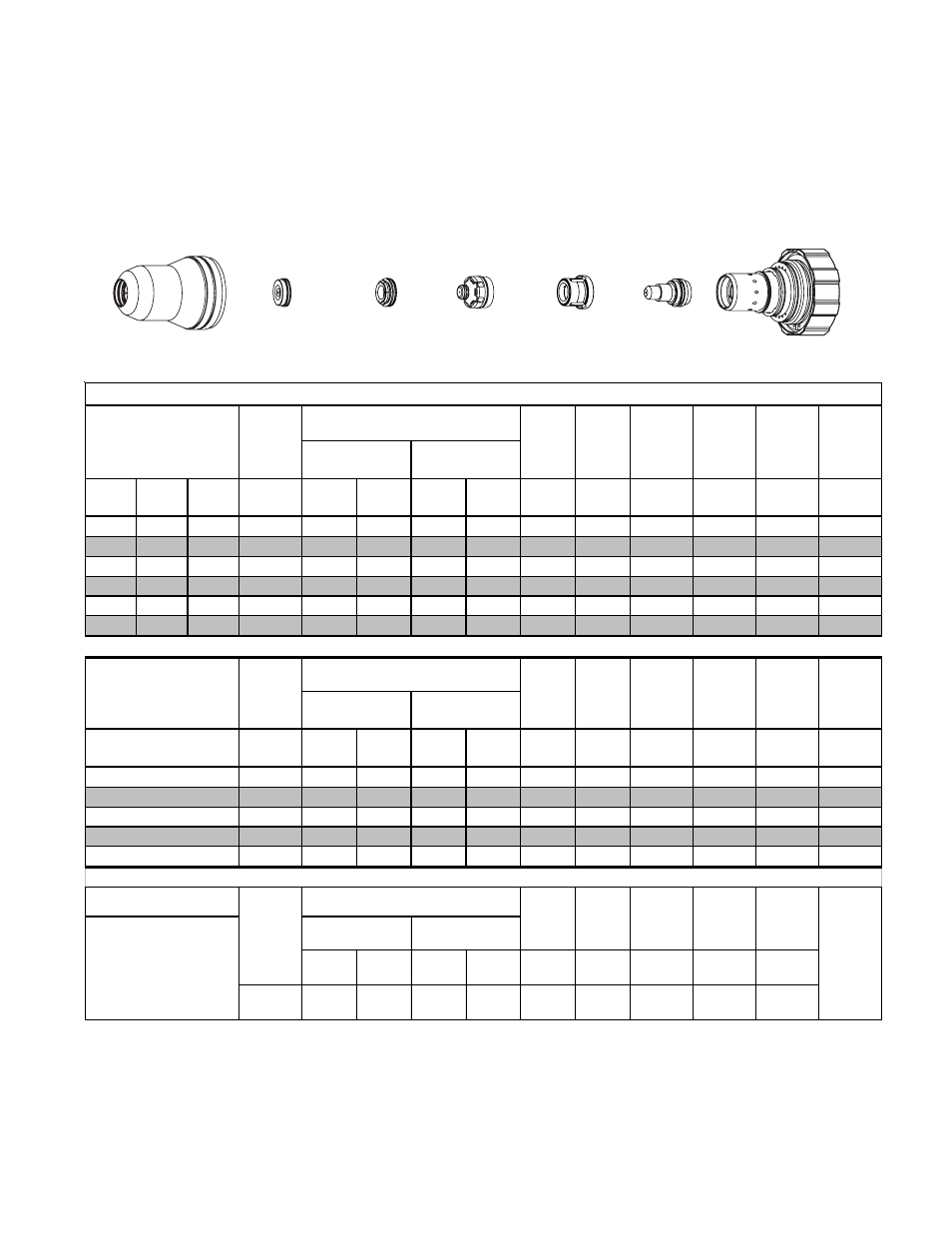

Cartridge

21-1020

Electrode

21-1068

Plasma

Gas Distributor

21-1040

Tip

21-1050

Shield Cap

21-1024

Shield Cup

21-1016

Art # A-06768

Shield

Gas Distributor

21-1082

(ga)

(in)

inch

(PSI)

Ball

(PSI)

Ball

(PSI)

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

20

0.036

60

22

120

21

120

128

0.050

130

0.120

0.2

0.058

16

0.060

60

22

120

21

120

143

0.050

60

0.120

0.3

0.070

14

0.075

60

22

120

21

120

145

0.070

45

0.120

0.3

0.072

12

0.105

60

22

120

21

120

148

0.110

40

0.150

0.3

0.074

10

0.135

80

22

120

21

120

154

0.130

30

0.150

0.3

0.085

3/16

0.188

80

22

120

21

120

154

0.120

25

0.150

0.4

0.075

(Bar)

Ball

(Bar)

Ball

(Bar)

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

4.1

22

8.3

21

8.3

130

1.3

3050

3.0

0.2

1.5

4.1

22

8.3

21

8.3

145

1.9

1130

3.1

0.3

1.8

4.1

22

8.3

21

8.3

150

3.0

910

3.8

0.3

2.0

5.5

22

8.3

21

8.3

154

3.2

710

3.8

0.3

2.1

5.5

22

8.3

21

8.3

155

3.0

640

3.8

0.4

1.9

Ball

Press

Ball

Press

Volts

In ±0.005 /

mm ± 0.1

ipm /

mm/min

In ±0.005 /

mm ± 0.1

(sec)

20psi

1.4 bar

20

40 psi

2.8 bar

70

80 psi

5.5 bar

145

0.1

2.5

300

7600

0.1

2.5

0

30A Mild Steel (O

2

/O

2

)

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf

Width

@ Rec.

Speed

Plasma (O

2

) Shield

(O

2

)

Material

Thickness

Pre Flow

Pressure

(Air)

Cut Flow Rates / Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Kerf

Width

@ Rec.

Speed

Plasma (O

2

) Shield

(O

2

)

(mm)

1

2

3

4

5

Marking (with 30A Mild Steel Parts)

15A Arc Current

Pre Flow

Pressure

(N

2

)

Cut Flow Rates / Pressures

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

M arking

Quality

Degrades

as

Thickness

Decreases.

Burn-through may

occur on

thicknesses

< 1/16" (0.063") /

1.6 mm

Plasma

Pressure (N

2

)

Shield

Pressure N

2

)