Quick wire trim unit – Tweco QWT-3 Quick Wire Trim Unit User Manual

Page 9

QUICK WIRE TRIM UNIT

3-5

SM-QWT-3

INSTALLATION AND OPERATION

SECTION 3:

INSTALLATION AND OPERATION

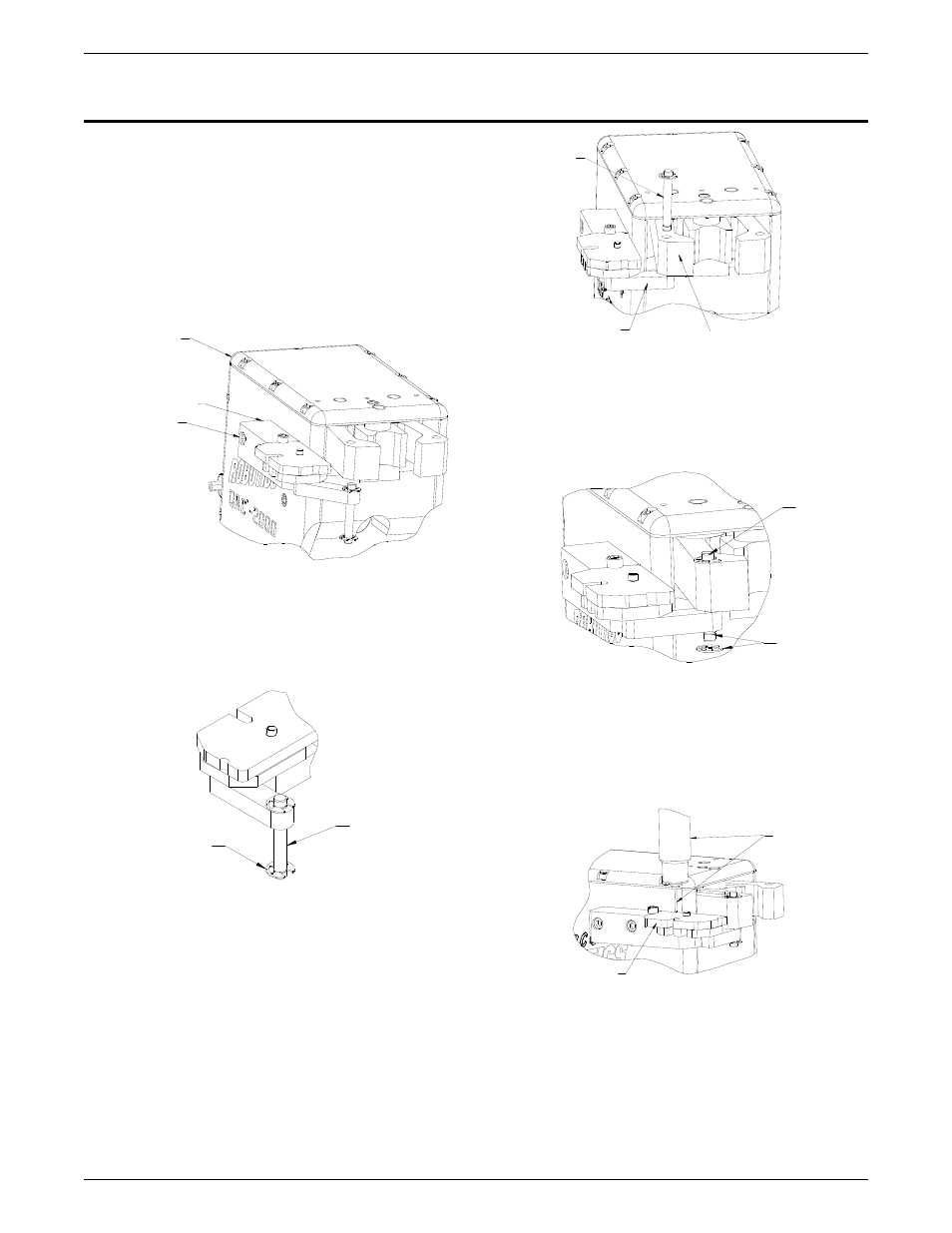

1. Remove the QWT-3 wire trim unit from the shipping

carton. Check to ensure the assembled unit is complete

as shown in Figure 1. If any of the component parts

are missing, please notify the local Tweco Welding

Distributor or Tweco Products Customer Service

Department at 1-800-426-1888.

2. Mount the wire trim unit to the QRC™-2000 cleaning

station using a ¼”-20 x 1” long socket head, for the

cap screws supplied. Refer to Figure 2.

Figure 2: Wire Trim Unit Mounted on Cleaning Station

CLEANING

STATION

QWT-3 WIRE

TRIM UNIT

1/4”-20

SOCKET HEAD

CAP SCREW (2

EACH)

3. Remove the retaining clip from the pivot arm and move

the pivot arm toward the clamp arm of the cleaning

station. Refer to Figure 3.

RETAINING RING

PIVOT PIN

Figure 3: Retaining Clip on Pivot Pin

4. Position the pivot arm on the wire trim unit so that the

hole for the pivot pin is aligned with the ¼” (6,35mm)

hole in the clamp arm.

5. Insert the pivot pin through the pivot arm on the wire

trim unit and clamp arm of the cleaning station. Refer

to Figure 4.

PIVOT PIN

PIVOT ARM

CLAMP ARM

6. Hold the pivot pin in position so that the retaining clip

that was removed in Step 3 can be reconnected. Refer

to Figure 5.

Figure 4: Alignment of Pivot Pin, Pivot Arm and Clamp Arm

PIVOT PIN

GROOVE FOR

RETAINING

RING

7. Position the robot arm with the conductor tube

assembly directly above the wire trim unit. When

positioned correctly, the wire will be positioned

between the wire guide of the wire trim unit. Refer to

Figure 6.

Figure 5: Pivot Pin in Place

Figure 6: Conductor Tube/Wire and Wire Trim Unit

CONDUCTOR

TUBE NOzzLE/

WIRE

WIRE GUIDE

8. Lower the robot arm and conductor tube assembly to

a height that will expose the correct amount of welding

wire after cutting occurs — the welding wire should

extend past the cutting blade on the wire trim unit. Refer

to Figure 7.