Wire cutting station – Tweco QWT-120 User Manual

Page 9

wire cutting station

3-5

sM-qWt-120

installation and opeRation

SECTION 3:

INSTAllATION AND OPERATION

1. Remove the QWT-120 Wire Trimmer from the shipping

carton.

2. Mount the QWT-120 unit onto a solid work table within

the envelope of the robot.

NOTE

the cutting path should be within reach of the

end of the welding wire, at the desired angle

of cut. the unit may be mounted in a vertical

upright position, or at an angle of up to 30°.

the mounting plate has four .406” Ø (11,03mm)

holes that allow the use of 3/8” Ø (9,53mm)

hex head bolts to secure the unit to the

worktable. Refer to figure 2.

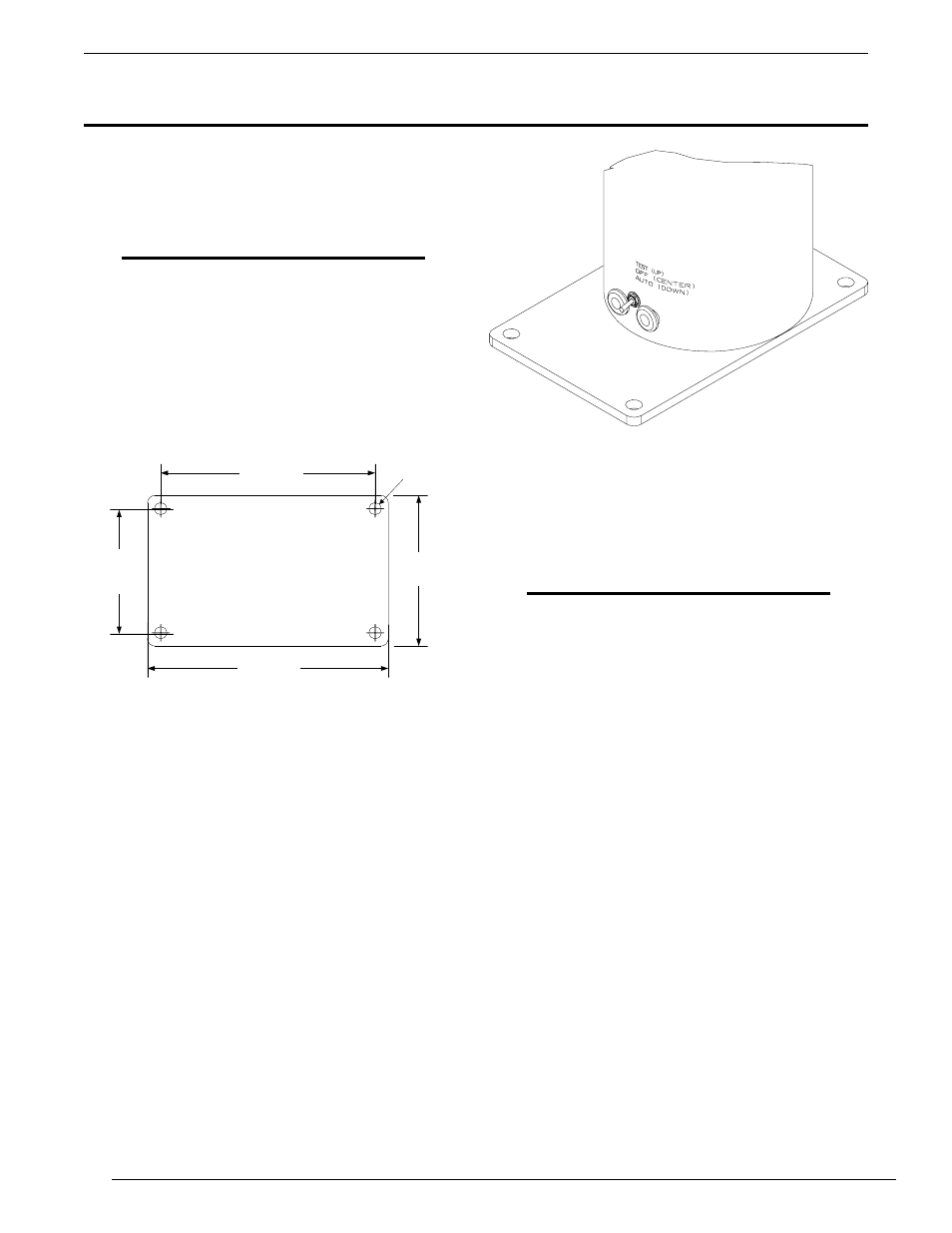

Figure 2: Mounting Hole Location

7.12”

(180,8mm)

4.12”

(104,6mm)

8.00”

(203,2mm)

5.00”

(127mm)

Ø 0.406”

(11,03mm)

3. Lay out the hole pattern on the work table surface.

Drill the four holes and secure the QWT-120 unit to

the work table surface.

4. Plug the 120-volt AC power cord into the appropriate

receptacle.

The motor is controlled by a 24-volt DC relay circuit

built into the unit. The operational mode switch

activates the relay circuit. The unit comes with a 22/2

PVC control cable to receive the 24-volt DC signal

from the robot controller to the QWT-120 unit. Refer

to Section 4: Wiring Diagram.

5. Connect the 2 conductor control wires to the

robot controller per the robot manufacture’s

recommendations.

A three position toggle switch is located on the outer

housing of the QWT-120 unit. Refer to Figure 3.

Figure 3: Test/Off/Auto Toggle Switch

The 3-position toggle switch is used as follows:

TEST (UP)

Allows the unit to function as long as

the switch is held in the UP position.

NOTE

Do not run the unit continuous, this may cause

overheating of the unit.

OFF (CENTER) Allows the unit to be turned off.

AUTO (DOWN) Allows the unit to be controlled ON or

OFF by the robot controller using the

24-volt DC signal.

6. Set the unit to the AUTO position.

7. The QWT-120 Unit is now ready to be used.