Wire cutting station, 01 how to use this manual, 02 receipt of equipment – Tweco QWT-120 User Manual

Page 8: 03 introduction, 04 features

wire cutting station

2-4

SM-qWt-120

intRoduction and descRiption

2.01 How to Use this Manual

To ensure safe operation, read the entire manual, including

the chapters on safety instructions and warnings.

Throughout this manual, the words WARNING, CAUTION,

and NOTE may appear. Pay particular attention to the

information provided under these headings. These special

annotations are easily recognized as follows:

WARNING

a WARNING gives infoRMation RegaRding

possible peRsonal injuRy.

CAUTION

a CAUTION refers to possible equipment

damage.

NOTE

a NOTE offers helpful information concerning

certain operating procedures.

2.02 Receipt of Equipment

When you receive the equipment, check it against the

invoice to make sure it is complete and inspect the

equipment for possible damage due to shipping. If there is

any damage, notify the carrier immediately to file a claim.

Furnish complete information concerning damage claims

or shipping errors to the location in your area listed in the

inside back cover of this manual. Include a full description

of the parts in error.

If you want additional or replacement copies of this CD,

please contact Tweco

®

Robotics at the address and phone

number in your area listed on the inside back cover of this

manual. Include the Manual number (from page i) and

CD part number: 64-2601.

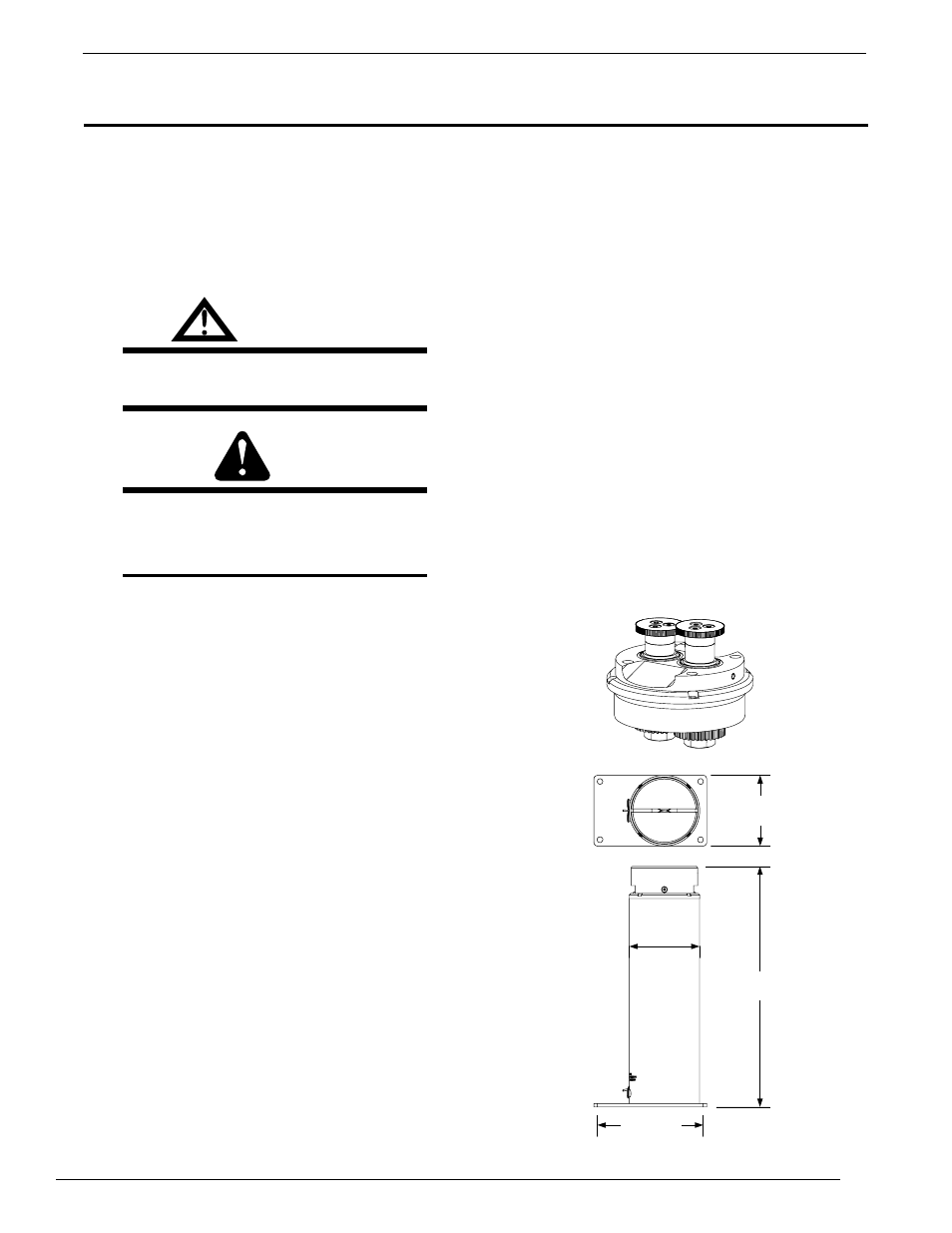

2.03 Introduction

The Tweco

®

Robotics QWT-120 Quick Wire Trimmer, is

an on-the-fly wire trimming station furnished with dual

cutting wheels as shown in Figure 1 that cleanly shear the

wire without deflection or bending of the welding wire.

SECTION 2:

INTRODUCTION AND DESCRIPTION

2.04 Features

Machined discs from heat-treated tool steel for long

life and economical performance.

Reversible cutting discs, doubles the disc’s life span,

designed for convenient replacement.

Unit is powered by a 120-volt AC motor with a relay

interface for controlling the start and stop cycle

through the robotic controller.

Unit is enclosed in a heavy-gauge aluminum tube,

with the head assembly machined from solid

aluminum.

Industrial components provide years of reliable

service.

The unit is able to cut the following wire sizes:

Steel Wire

From .023” (0,6mm) to 5/64” (2,0mm)

Aluminum

Wire

From .030” (0,8mm) to 3/32” (3,2mm)

Flux Cored

Wire

From .030” (0,8mm) to 3/32” (3,2mm)

Metal Cored

Wire

From .030: (0,8mm) to 3/32” (3,2mm)

•

•

•

•

•

5.00”

(127mm)

17.00”

(432,5mm)

7.50”

(190,5mm)

5.00”

(126,4mm)

Figure 1