09 install wire into the welding gun, Install wire into the welding gun -5, Installation firepower fp-95 – Tweco FP-95 Mini MIG User Manual

Page 25

INSTALLATION

FIREpOwER Fp-95

Installation

3-5

Manual 0-5122

3.09 Install Wire into the Welding Gun

1. Plug the Welding Power Source into the 120VAC

receptacle.

WARNING

ELECTRIC SHOCK CAN KILL! With the gun

switch (located on the gun) activated, weld-

ing power is applied to the output terminals,

feedroll, ground clamp, gun cable connection

and welding wire. Do not touch these parts

with the gun switch activated.

2. Turn the welding machine ON with the front panel

Voltage Power Switch set to "Min"

MIN

MAX

Art # A-09073

Figure 3--7: Power ON

3. Set the wire feed speed to half-way or "5".

MIN

MAX

Art # A-09073

Figure 3-8: Wire Speed Half-way

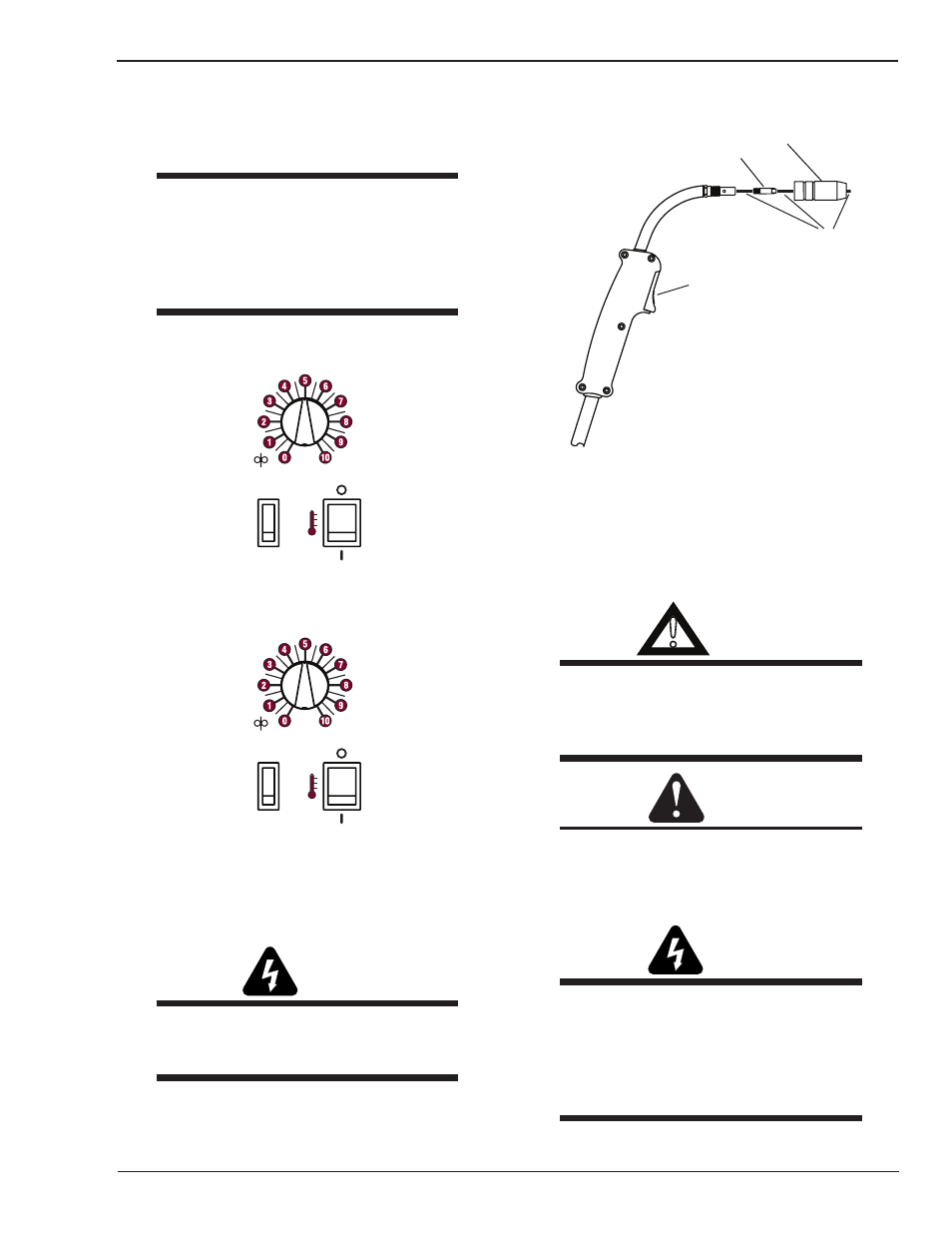

4. Straighten the gun cable. Remove the nozzle and

contact tip from the MIG welding gun (see Section

2.08).

WARNING

If ground connection clamp is in place on the

workpiece the electrode wire is electrically

“hot” when the gun switch is activated.

5. Activate the gun switch until the wire feeds

out past the gun nozzle and deactivate the gun

switch.

Contact Tip

Nozzle

Gun Switch

Wire

Art # A-09074

Figure 3-9: Feed Wire Through Gun

6. Set the Voltage Power Switch to "OFF" and unplug

the supply cord.

7. Replace the contact tip and nozzle. Cut the wire

within ¼” (6mm) from the nozzle.

!

WARNING:

The drive rollers, when moving, may crush the

fingers. Periodically, check the drive rollers.

Replace them when they are worn and com-

promise the regular feeding of the wire.

CAUTION:

The FP-95’s welding torch is a “live” contact

torch and is ALWAYS in the power on position.

Wear eye protection at all times when handling

this torch.

WARNING

ELECTRIC SHOCK CAN KILL! With the gun

switch (located on the gun) activated, weld-

ing power is applied to the output terminals,

feedroll, ground clamp, gun cable connection

and welding wire. Do not touch these parts

while the gun switch is activated.