Solid wire flux cored wire, Fabricator 210 – Tweco 210 MIG Thermal Arc Fabricator User Manual

Page 48

FABRICATOR 210

OPERATION

4-10

Manual No. 0-4855

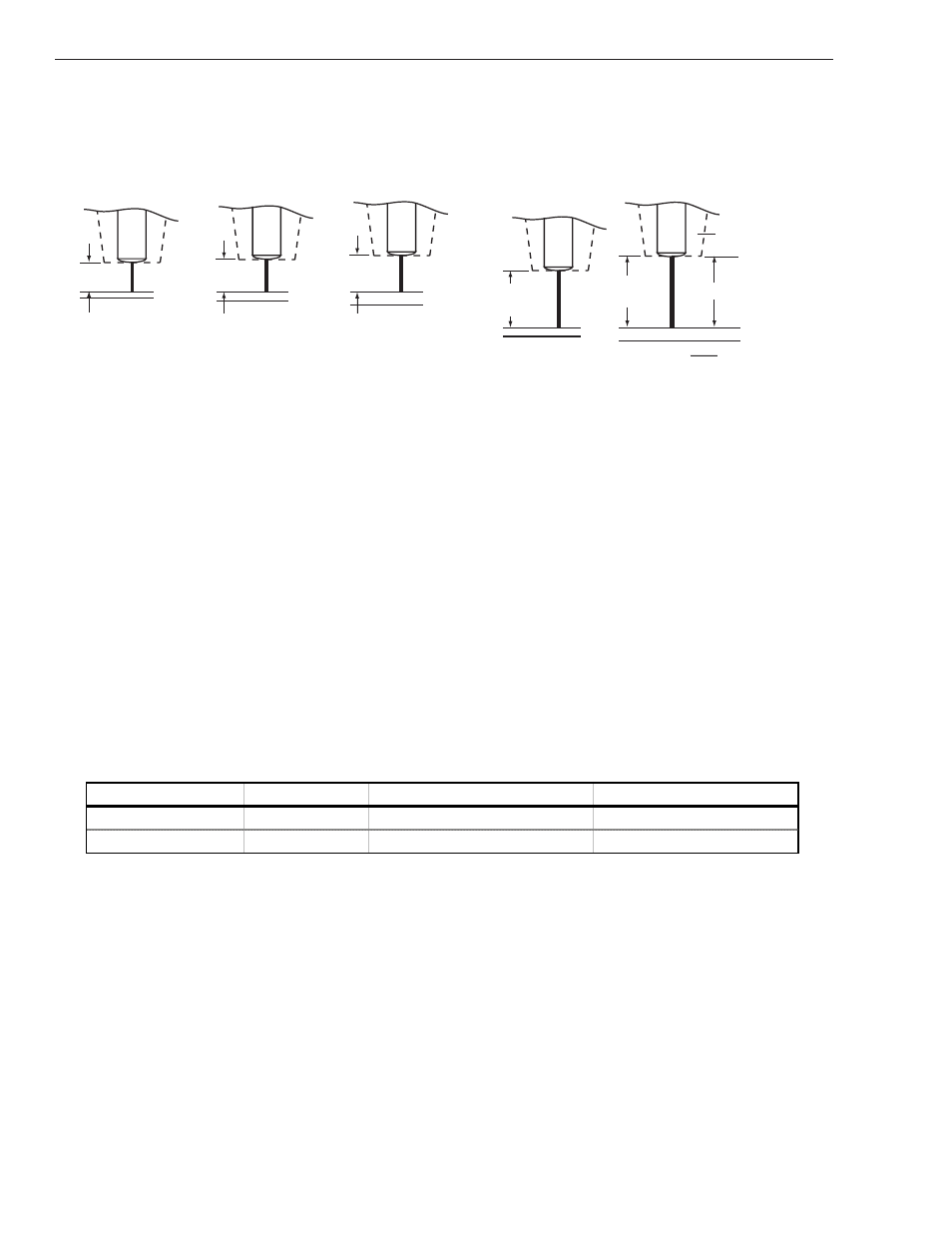

Distance from the MIG Gun Nozzle to the Work Piece

The electrode stick out from the MIG gun nozzle should be between 5/64" (2.0mm) to 13/64" (5.0mm). This distance

may vary depending on the type of joint that is being welded.

Contact

Ti

p

Gas

Nozzle

Solid Wire

Flux Cored Wire

.023”

(.6mm)

1/4” (6.4mm)

5/16” (7.9mm)

3/8” (9.5mm)

9/16”

(14.3mm)

11/16”

(17.5mm)

.030”

(.8mm)

.035”

(.9mm)

.035”

(.9mm)

.045”

(1.1mm)

Art # A-07186

Wire Diameter

Distance: ±1/16”

Figure 4-16: Optimum Contact Tip to Work Distances

Electrode Wire Size Selection

The choice of electrode wire size in conjunction with shielding gas used depends on:

- Thickness of the metal to be welded,

- Type of joint,

- Capacity of the wire feed unit and power supply,

- The amount of penetration required,

- The deposition rate required,

- The bead profile desired,

- The position of welding and

- Cost of the electrode wire.

Weld metal deposition rate is proportional to current density. Current density is defined as the current per cross

sectional area of the electrode wire and is normally expressed as amps per mm

2

. An example is in Table 4-3 below.

Electrode Wire Size Current (Amps) Current Density(Amps/mm2) Deposition Rate(lbs/hour)

.035”( 0.9mm)

200

314

7.0

.045”(1.2mm)

200

177

6.2

Table 4-3: Wire Deposition Rate