Tweco 300 TS Arcmaster(April2006) User Manual

Page 31

25

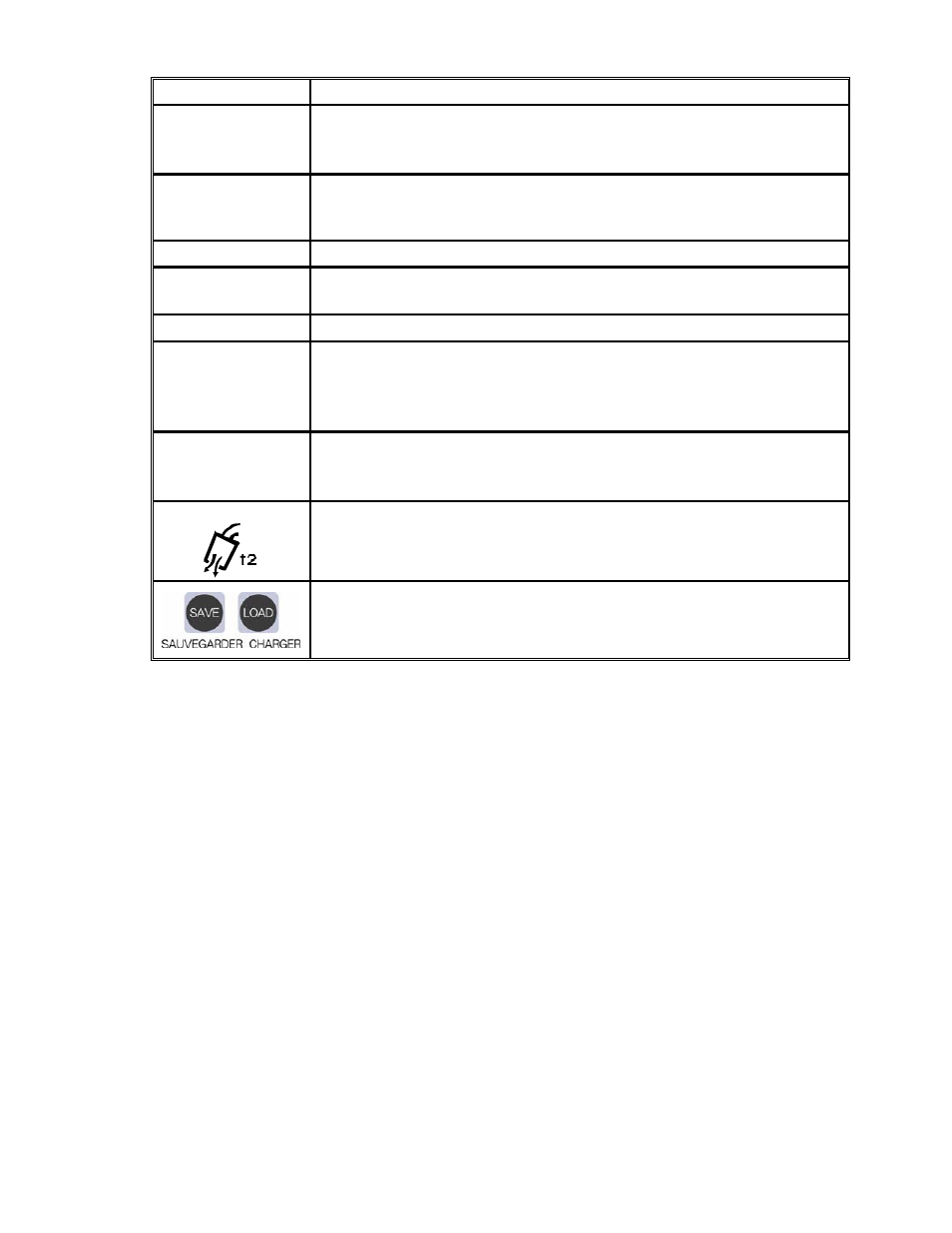

Parameter

Description

WELD

This parameter sets the TIG WELD current in

STD

,

SLOPE

,

REPEAT

and

SPOT

modes when

PULSE

is OFF. This parameter also sets the STICK

weld current.

BASE

(Background

Current)

This parameter sets the Background current when in Pulse TIG mode.

SPOT TIME

This parameter sets the duration of the

SPOT TIME

in

HF TIG

mode only.

PULSE WIDTH

This parameter sets the percentage on time of the

PULSE FREQUENCY

for

PEAK weld current when the

PULSE

is ON.

PULSE FREQ.

This parameter sets the

PULSE FREQUENCY

when the

PULSE

is ON.

DOWN SLOPE

This parameter operates in TIG modes only and is used to set the time for the

weld current to ramp down, after the torch trigger switch has been pressed,

to

CRATER CUR.

This control is used to eliminate the crater that can form at

the completion of a weld.

CRATER CUR.

This parameter operates in

SLOPE

or

REPEAT

(4T) TIG modes only and is

used to set the finish current for TIG. The CRATER Current remains ON until

the torch trigger switch is released after it has been depressed.

POST-FLOW

This parameter operates in TIG modes only and is used to adjust the post gas

flow time once the arc has extinguished. This control is used to dramatically

reduce oxidation of the tungsten electrode.

The SAVE/LOAD buttons are used to save and retrieve a total number of 5

programs into the 300 TS memory.

Table 4 – Weld Parameter Descriptions for ArcMaster 300 TS