Safety instructions thermal arc 161 s – Tweco 161 S Inverter Arc Welder User Manual

Page 11

SAFETY INSTRUCTIONS

THERMAL ARC 161 S

Manual 0-5199

1-5

Safety Instructions

C Ventilation

!

WARNING

Ade quately ventilate welding, heating, and cutting work

areas to prevent accumulation of explosive or toxic

concen trations of gases. Certain combinations of metals,

coatings, and gases generate toxic fumes. Use respira-

tory protection equipment in these circumstances. When

welding/brazing, read and understand the Material Safety

Data Sheet for the welding/brazing alloy.

D Personal Protection

Gas flames produce infrared radiation which may have a harm ful effect

on the skin and especially on the eyes. Select goggles or a mask with

tempered lenses, shaded 4 or darker, to protect your eyes from injury

and provide good visibility of the work.

Always wear protective gloves and flame-resistant clothing to protect skin

and clothing from sparks and slag. Keep collars, sleeves, and pockets

buttoned. DO NOT roll up sleeves or cuff pants.

When working in a non-welding or cutting environment, always wear

suitable eye protection or face shield.

!

WARNING

Practice the following safety and operation precautions

EVERY TIME you use pressure regulation equipment.

Deviation from the following safety and operation

instructions can result in fire, explosion, damage to

equipment, or injury to the operator.

E Compressed Gas Cylinders

The Department of Transportation (DOT) approves the design and

manufacture of cylinders that contain gases used for welding or cut-

ting operations.

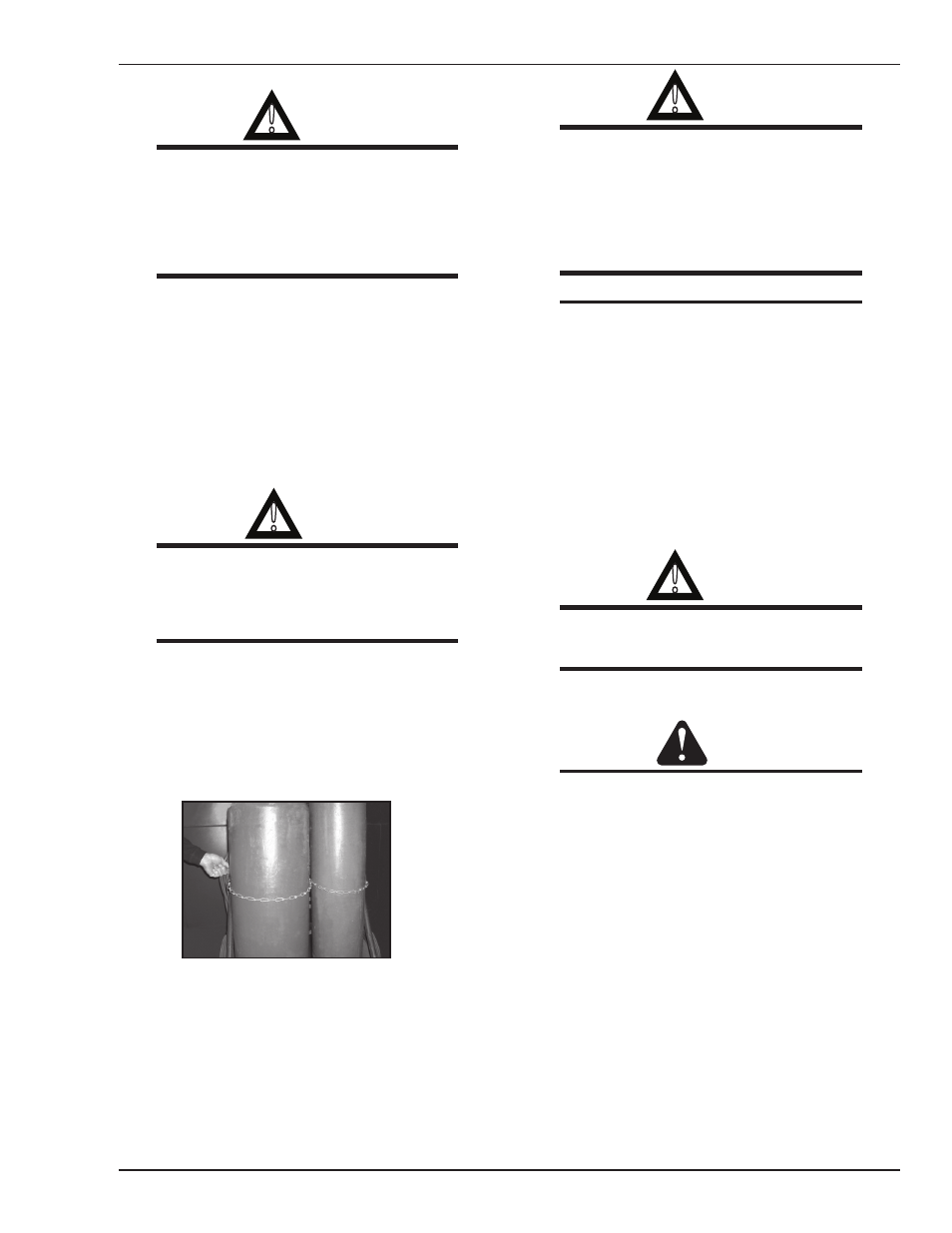

1. Place the cylinder (Figure 1-1) where you will use it. Keep the

cylinder in a vertical position. Secure it to a cart, wall, work bench,

post, etc.

Figure 1-1: Gas Cylinders

!

WARNING

Cylinders are highly pressurized. Handle with care.

Serious accidents can result from improper handling

or mis use of compressed gas cylinders DO NOT drop

the cylinder, knock it over, or expose it to excessive

heat, flames or sparks. DO NOT strike it against other

cylinders. Contact your gas supplier or refer to CGA P-1

“Safe Handling of Compressed Gases in Containers”

publication.

NOTE

CGA P-1 publication is available by writing the Com-

pressed Gas Association, 4221 Walney Road, 5th Floor,

Chantilly,VA 20151-2923

2. Place the valve protection cap on the cylinder whenever mov ing

it, placing it in storage, or not using it. Never drag or roll cylinders

in any way. Use a suitable hand truck to move cylin ders.

3. Store empty cylinders away from full cylinders. Mark them

“EMPTY” and close the cylinder valve.

4. NEVER use compressed gas cylinders without a pressure reducing

regulator attached to the cylinder valve.

5. Inspect the cylinder valve for oil, grease, and damaged parts.

!

WARNING

DO NOT use the cylinder if you find oil, grease or dam-

aged parts. Inform your gas supplier of this condition

immediately.

6. Momentarily open and close (called “cracking”) the cylinder valve

to dislodge any dust or dirt that may be present in the valve.

CAUTION

Open the cylinder valve slightly. If you open the valve

too much, the cylinder could tip over. When cracking

the cylinder valve, DO NOT stand directly in front of

the cylinder valve. Always perform cracking in a well

ventilated area. If an acetylene cylinder sprays a mist

when cracked, let it stand for 15 minutes. Then, try to

crack the cylinder valve again. If this problem persists,

contact your gas supplier.