Drag-gun™ lt – Tweco 15C Drag-Gun LT User Manual

Page 22

Operation

4-2

Manual 0-4965

Drag-gun™ lt

Connect Work Cable

Make a solid work cable

connection to the work-

piece or cutting table

A-02022

Torch Operation

• Wear gloves and protective goggles.

• Do not place bare hand on work piece.

1. For drag cutting, keep the torch in con-

tact with the work piece.

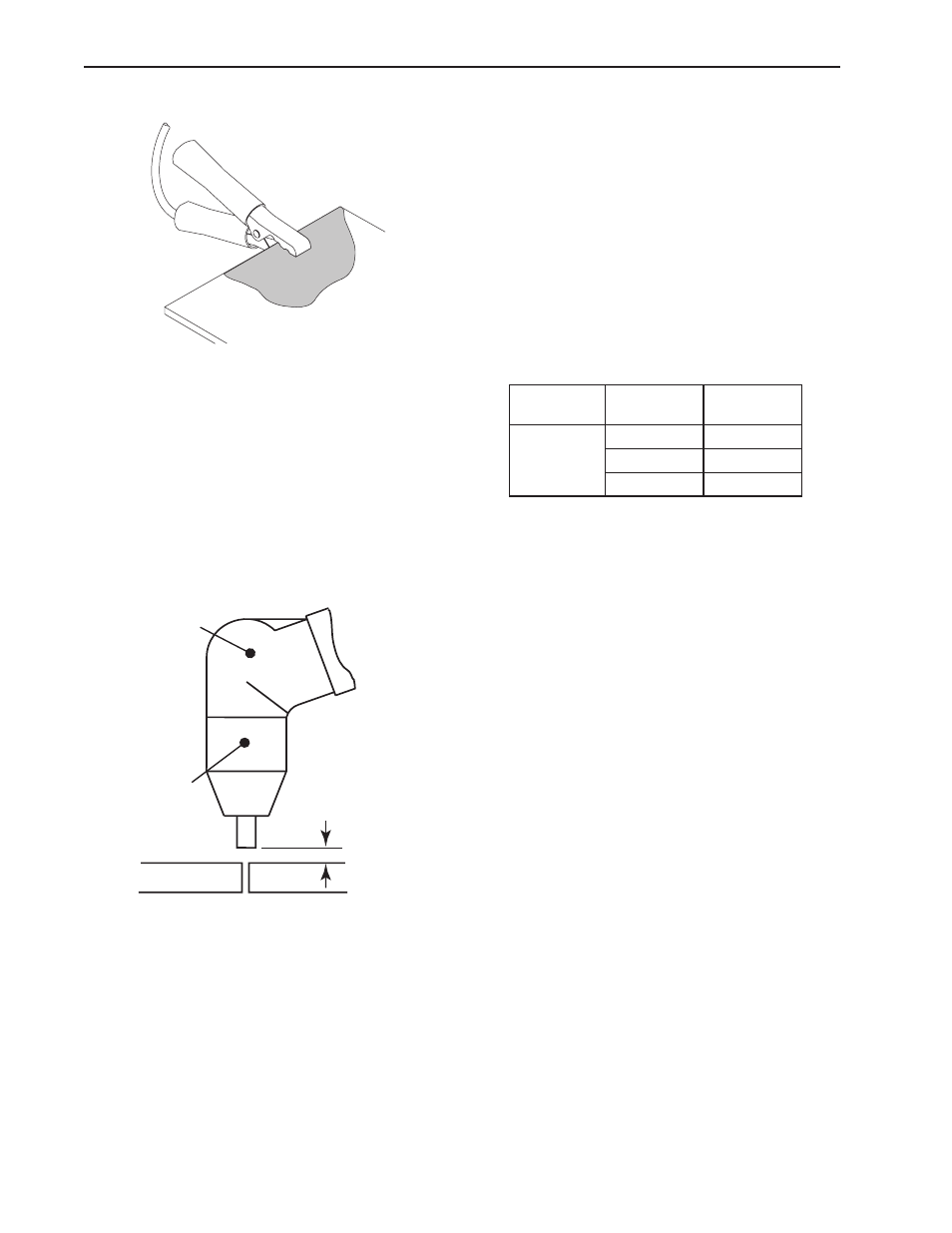

2. For standoff cutting, hold the torch 1/8

- 3/8 in (3-9 mm) from the work piece as

shown below.

A-00024

Shield Cup

Torch

Standoff

Distance 1/8" - 3/8"

3. With the torch in starting position, press

and hold the Torch Trigger. The pilot arc

will come on and remain on until the cut-

ting arc starts.

4. Once on, the cutting arc remains on as

long as the Torch Trigger is held down.

5. To shut off the torch simply release the

Torch Trigger. When the trigger is re-

leased a gas post-flow will occur. If the

Torch Trigger is pushed during the post-

flow, the pilot arc will restart immediately

and the cutting arc will restart when the

torch is brought within range of the work

piece.

Typical Cutting Speeds

Cutting speeds vary according to torch output,

the type of material being cut, and operator skill.

Speeds shown are typical for this cutting system

using air plasma to cut materials shown.

Material

Material

Inches Per

Mild Steel

1/8”

25.0

3/16”

16.0

1/4”

slow speeds