Hand-held operation – Triton JOF 001 User Manual

Page 7

7

GB

Functions / Hand-Held Operation

HAND-HELD OPERATION

• Put on all safety equipment required to use this tool

• Ensure your workpiece is

securely clamped to prevent

any movement during

operation

• Hold the router firmly using

both hands to control the

router and keep an even

pressure and movement

when cutting

• Never operate the router freehand without some form

of guide. Guidance can be provided by a bearing guided

cutter, the fence guide supplied, or a straight edge

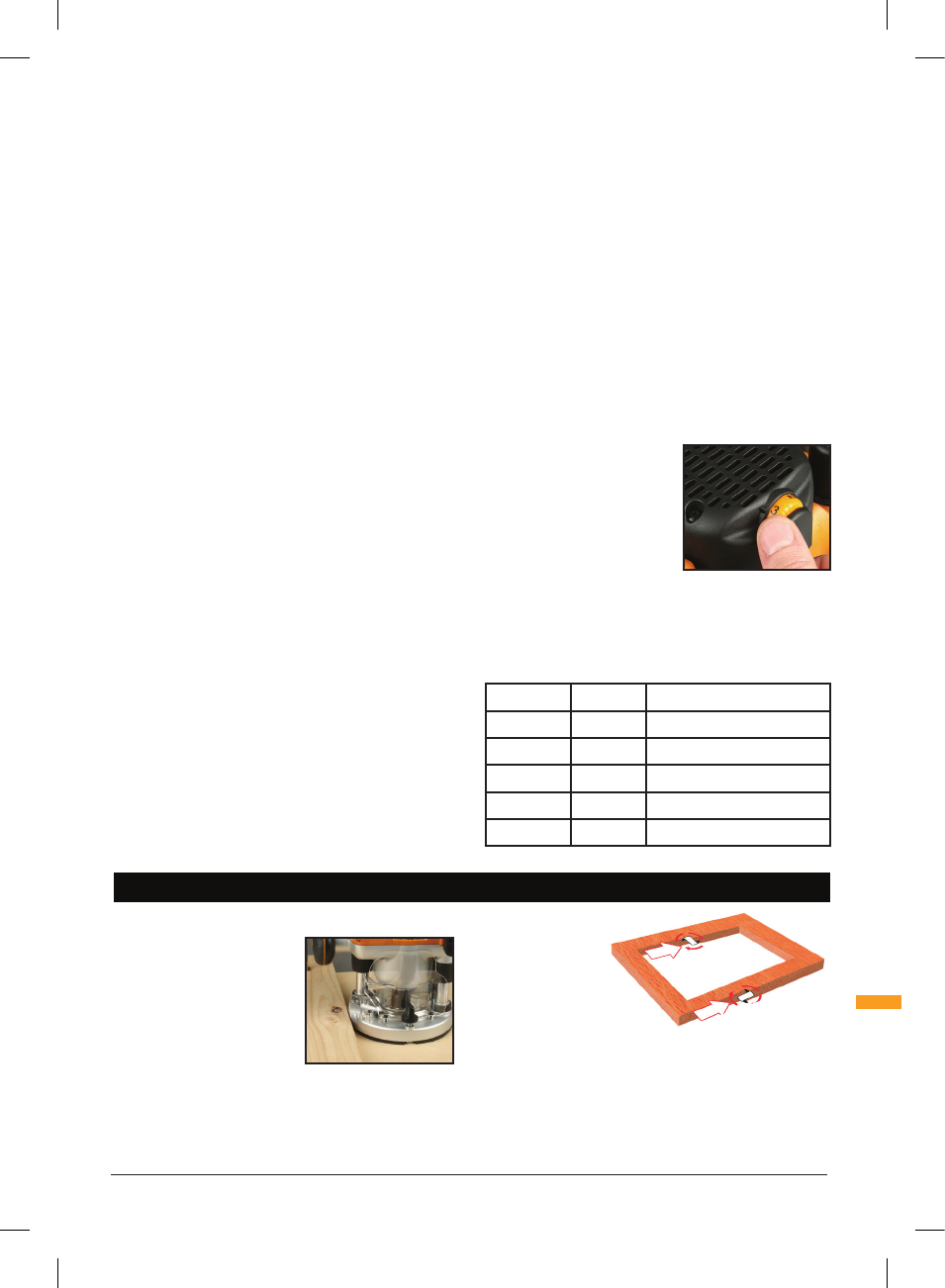

• Always feed against

the direction

of cutter

rotation. The

cutter rotates

clockwise (as

indicated by the arrows

on the base adjacent to

the

baseplate

mounting knobs)

• Do not operate the router upside down unless securely

mounted in a well guarded router table (for example,

the Triton Router Table)

2. Insert the router bit fully into the collet, then use the

spanner to tighten the collet so that it holds the bit firmly

3. Hold the body of the machine securely and disengage

the plunge lock lever. This will release the collet lock

and the power lock out cover

DUST EXTRACTION

Dust Port

• The Triton JOF Router is equipped with a Dust

Extraction Port (6) for chip extraction above the cut.

It accepts 38mm (1-½") O.D. hose, supplied with the

Triton Dust Collector (DCA300)

• The hose screws into position via a left hand thread

(anticlockwise)

DEPTH STOP & TURRET

• The Depth Stop (11) and Turret (9) enable accurate pre-

setting of two different cut depths

Zeroing the router

1. Fit the router bit you require and place the router, right

side up, on the work bench

2. Rotate the Turret (9) until the fixed post is beneath the

depth stop

3. Loosen the Depth Stop Lock Knob (11) so that the

depth stop is fully released

4. Release the Plunge Lock Lever (7), then plunge the

router until the tip of the bit is in contact with the

surface of the work bench

5. Now tighten the depth stop lock knob so that the depth

stop is locked in its current position

Pre-setting the cut depths

1. The top of the fixed post now provides an accurate

datum, and the depth of cut can be set by reference to

the graduations printed on the side of the fixed post

2. To set a cut depth, rotate the thumbwheel on one of the

Turret Stops (9) until the top of the thumbwheel aligns

with the depth of cut required (as shown on the fixed

post) For example, for a cutting depth of 3mm, rotate

the thumbwheel until the top is aligned with the 3mm

mark on the fixed post.

3. To pre-set a second depth, repeat the procedure with

the second thumbwheel

Plunging to pre-set depth

• Rotate the turret until the thumbwheel at the required

depth is positioned beneath the depth stop

• Now, when you plunge the router, the depth stop will

hit the thumbwheel and retain the router at the precise

depth required

VARIABLE SPEED CONTROL

• Router speed settings are not critical - generally the

highest speed which does not result in burn marks on

the workpiece should be used. Where stated, always

follow the cutter manufacturer's maximum speed

limitations

• Generally, higher speeds are

used for timber and MDF,

lower speeds for synthetic

materials

• Operating at reduced speed

increases the risk of damage

to the router as a result of

overload. At low speeds use

very slow feed rates and/or

multiple shallow cuts

• The Speed Controller (1) is marked 1 to 5, corresponding

approximately with the speeds and cutter diameters

below. Turn the dial to select the speed required

Setting

RPM

Cutter Diameter

5

20,000

Up to 25mm (1")

4

18,000

25 – 50mm (1" – 2")

3

14,500

50 – 65mm (2" – 2-

1

⁄

2

")

2

11,000

Over 65mm (2-

1

⁄

2

")

1

8,000

Use only if burning

925837_Z1MANPRO1.indd 7

13/11/2013 16:46